- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

as demand

-

Weight (T):

-

5 T

-

Power (kW):

-

350

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

tianli

-

Voltage:

-

380

-

Dimension(L*W*H):

-

as demand

-

Weight (T):

-

5 T

-

Power (kW):

-

350

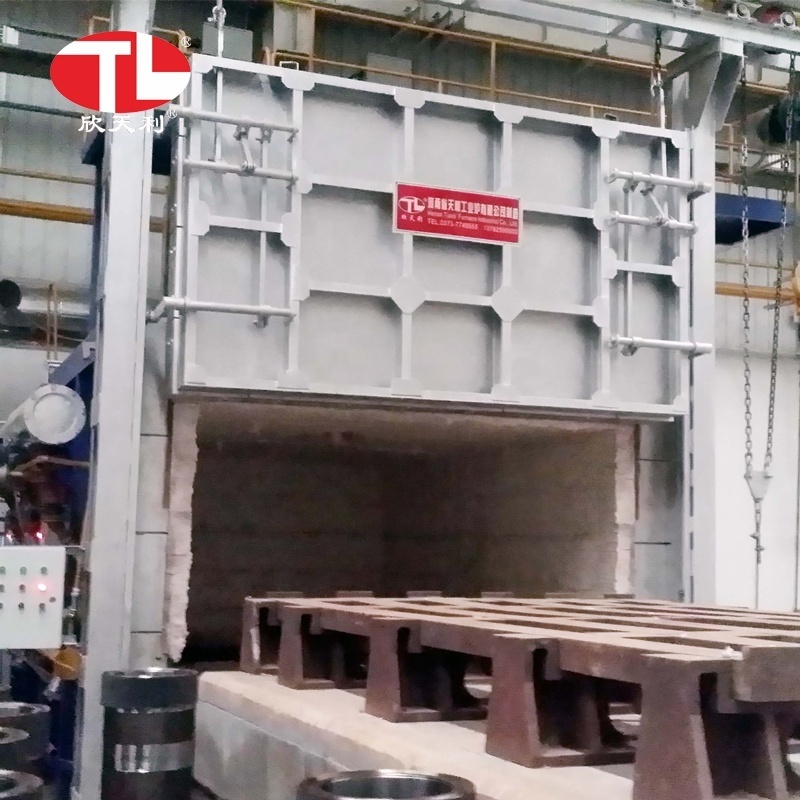

gas fired heat storage heating furnace for casting and forging industry:

An independent storage chamber or a storage burner that can preheat air or gas. For various types of heating furnace, can also be used for high temperature heat treatment furnace.

In essence, the regenerative heating furnace is the combination of the regenerative heat exchanger and the conventional heating furnace, mainly composed of the furnace body, heat storage room, reversing system, fuel, air supply and smoke exhaust system.

style="border: 0px; box-sizing: border-box; margin: 0px; padding: 0px; font-style: inherit; font-weight: inherit; font-size: 0px; line-height: 0px; vertical-align: baseline; width: 750px; height: 819px; overflow: hidden;">

Merit of gas fired heat storage heating furnace :

1. The furnace temperature is more uniform

2. The heating quality is greatly improved

3. The qualified rate of products has been greatly improved

4. Reactive combustion can also improve the flame radiation intensity, strengthen the radiation heat transfer, and increase the furnace output

5. Fuel selection range is more suitable for light oil, heavy oil, natural gas, liquefied petroleum gas and other fuels

6. Stove fuel consumption is greatly reduced. For the general large heating furnace, can be 25%~30%; for the heat treatment furnace, can be 30%~65%.

7. The low NOx content in the flue gas is conducive to environmental protection.

Installation and trial start

1. For small furnace ,we will finish the installation and debugging of the furnace in our factory .

2. For big equipment,like ,gas furnace ,bogie hearth furnace ,and large scale electric resistance ,we provide overseas installation and debugging services.

Related spare parts:

Spare parts including :Loading basket,muffle,Kanthal heating element,radiant tube heater,loading rack ,Refactory insulation fiber,insulation bricks and so on.