- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V-440V

-

Dimension(L*W*H):

-

As per order

-

Weight:

-

125 KG

-

Motor:

-

Vertical Vibrating Motor

-

Material:

-

Carbon Steel/Stainless Steel 304/316L

-

Function:

-

Screening\separation\sorting\sieving

-

Layer(s):

-

1-5 Layers

-

Surface treatment:

-

Mirror Polishing & Sandblast & Paint

-

Screen Mesh:

-

5 - 500 Mesh

-

Motor type:

-

YZUL-series Vertical Vibrating Motor

-

Diameter:

-

400-2000mm

-

Capacity:

-

100Kg-10Tons/hour

-

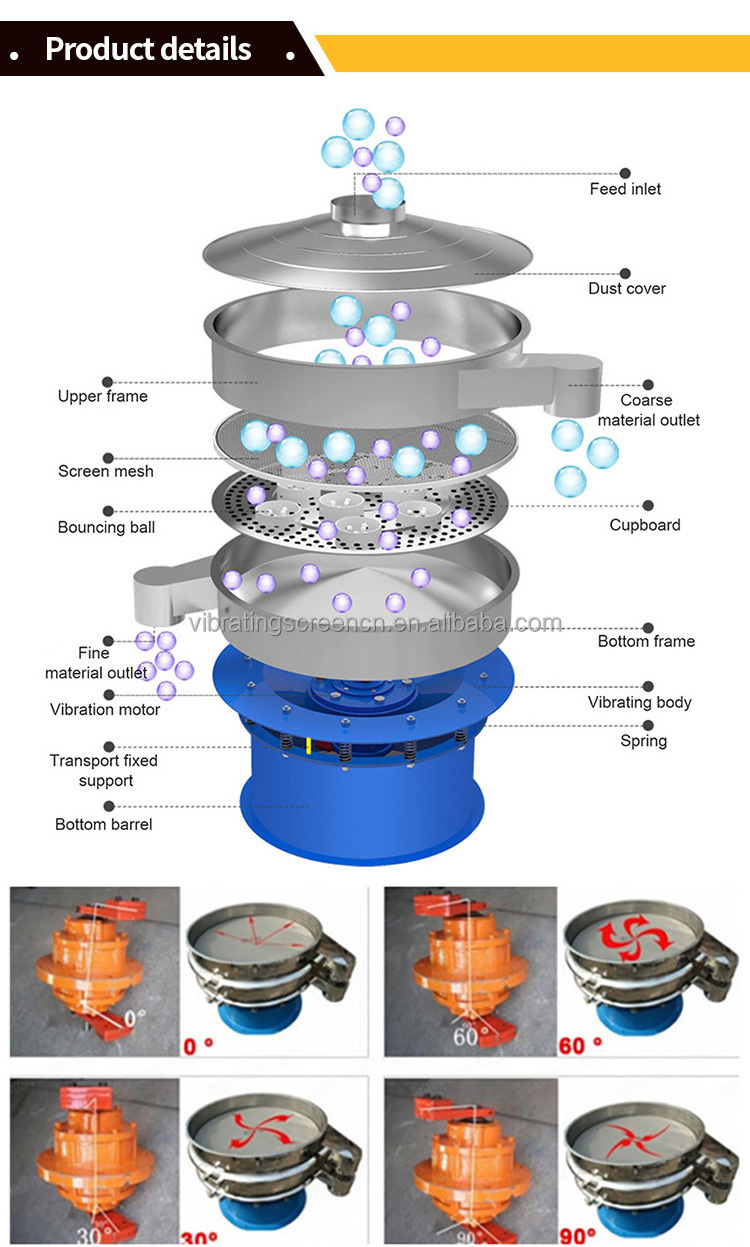

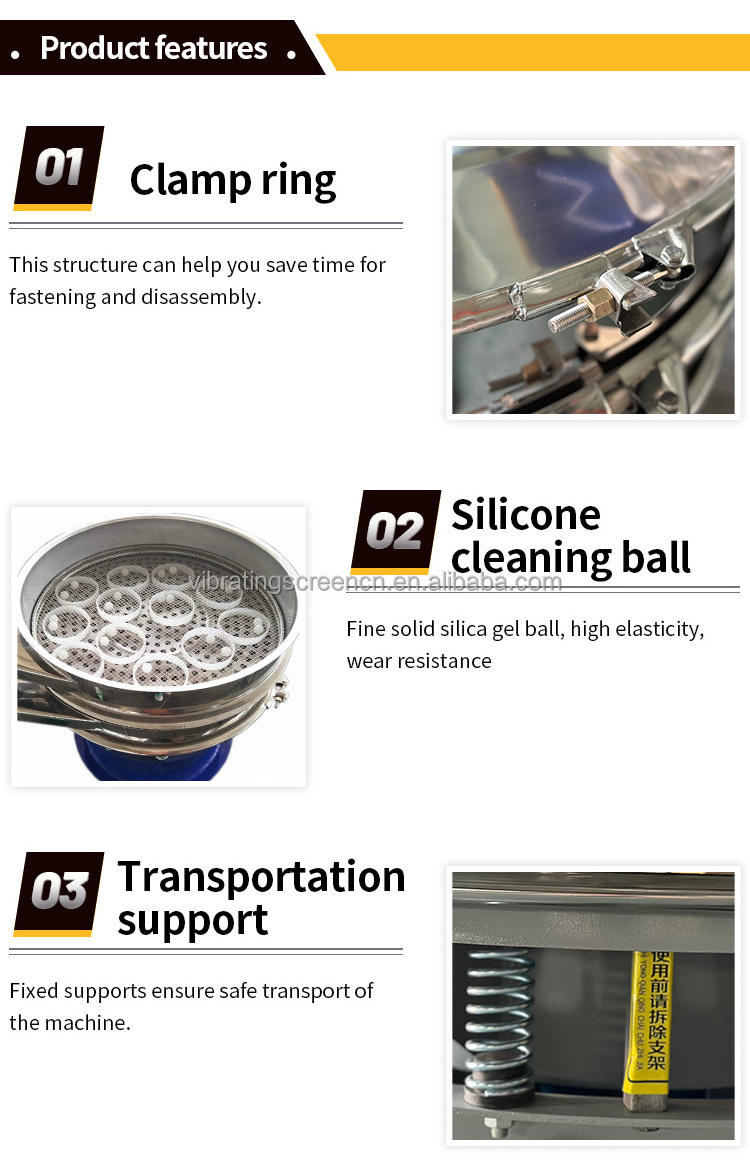

Cleaning system:

-

Bouncing Ball/Ultrasonic System

Quick Details

-

Type:

-

Circular/ Food processing

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

ZHONGCHENGYOU

-

Voltage:

-

220V-440V

-

Dimension(L*W*H):

-

As per order

-

Weight:

-

125 KG

-

Motor:

-

Vertical Vibrating Motor

-

Material:

-

Carbon Steel/Stainless Steel 304/316L

-

Function:

-

Screening\separation\sorting\sieving

-

Layer(s):

-

1-5 Layers

-

Surface treatment:

-

Mirror Polishing & Sandblast & Paint

-

Screen Mesh:

-

5 - 500 Mesh

-

Motor type:

-

YZUL-series Vertical Vibrating Motor

-

Diameter:

-

400-2000mm

-

Capacity:

-

100Kg-10Tons/hour

-

Cleaning system:

-

Bouncing Ball/Ultrasonic System

Rotary vibrating screen is a general vibration screening, filtration equipment, It has good application in the powder, granular and liquid materials. Our XZS series rotary vibrating screen is a new type of high-efficiency screening equipment developed based on years of production experience and combined with the actual situation of customers.

Technical Parameter

|

Model |

Layer |

Granularity (mm) |

Sieve mesh |

Effective Diameter (mm) |

Power(kw) |

|

XZS-400 |

1-4 |

<20 |

3-500mesh |

380 |

0.25 |

|

XZS-600 |

1-4 |

<20 |

3-500mesh |

600 |

0.55 |

|

XZS-800 |

1-4 |

<30 |

3-500mesh |

750 |

0.75 |

|

XZS-1000 |

1-4 |

<30 |

3-500mesh |

900 |

1.1 |

|

XZS-1200 |

1-4 |

<30 |

3-500mesh |

1100 |

1.5 |

|

XZS-1500 |

1-4 |

<50 |

3-500mesh |

1450 |

2.2 |

|

XZS-1800 |

1-4 |

<50 |

3-500mesh |

1750 |

3.0 |

FAQ

Q: What information do we need to help you choose a perfect machine?

1. Name and feature of the raw material

2.Aim of using: get rid of impurity, filtration, grading

3.granularity distribution

4.Handling capacity: kg /h, L/h

5.The raw material size: (mesh or mm)

6.The moisture of the material

7.The material of construction (stainless steel SUS 304 or 316, carbon steel Q 235 A)

8.How many layers you need?

9.The voltage , frenquency, phase (single or three)

Note: You'd better send us the relevent pictures or some materials you want to sift , it can assure us to recommend the suitable machine for you.

Q:Can I ask some special and customize design?

A: Yes, we can make a suitable machine for you according to your request.

Q:What is the real delivery time of your factory?

A: 7 to 15 days for general series products, meanwhile, batches products & customized products would need 30 days to 60 days based

on different situations.