1. High power exhaust fan: 550W

2. Pump

3. Industrial water cooling system

4. Exhaust pipe

5. Equipment commonly used maintenance tools

- Product Details

- {{item.text}}

Quick Details

-

Control System Brand:

-

RuiDa

-

Cutting Area:

-

900*600MM

-

Cutting Thickness:

-

10mm (For Example: acrylic) As to material

-

Place of Origin:

-

Beijing, China

-

Brand Name:

-

Mintec

-

Weight (KG):

-

400 KG

-

Type:

-

Water Cooling CO2 Laser Cutting Machines

-

Product name:

-

Laser Cutter

-

After-sales Service Provided:

-

Online Support

-

Name:

-

Precision Fiber Laser Cutting Machine

-

Cutting materials:

-

Acrylic Wood Mdf Plywood Plactical

-

Laser-type:

-

Green Picosecond/Infrared Picosecond/CO2

-

After Warranty Service:

-

Support Online Support

-

Color:

-

Opitional

-

Keyword:

-

Co2 Laser Cuting Machine

-

Cooling system:

-

Water Chiller Cooling System

Quick Details

-

Laser Type:

-

CO2

-

Cutting Speed:

-

0-30000mm/min

-

Cooling Mode:

-

WATER COOLING

-

Control System Brand:

-

RuiDa

-

Cutting Area:

-

900*600MM

-

Cutting Thickness:

-

10mm (For Example: acrylic) As to material

-

Place of Origin:

-

Beijing, China

-

Brand Name:

-

Mintec

-

Weight (KG):

-

400 KG

-

Type:

-

Water Cooling CO2 Laser Cutting Machines

-

Product name:

-

Laser Cutter

-

After-sales Service Provided:

-

Online Support

-

Name:

-

Precision Fiber Laser Cutting Machine

-

Cutting materials:

-

Acrylic Wood Mdf Plywood Plactical

-

Laser-type:

-

Green Picosecond/Infrared Picosecond/CO2

-

After Warranty Service:

-

Support Online Support

-

Color:

-

Opitional

-

Keyword:

-

Co2 Laser Cuting Machine

-

Cooling system:

-

Water Chiller Cooling System

Product Description

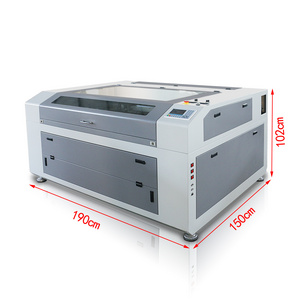

9060V adopts V-series transmission components, rail guide system, shaft movement components, mechanical components are more scientific and reasonable, which cutting performance is more perfect.

|

Frame

|

◆ High strength rack design

◆ Reasonable case design concept |

|

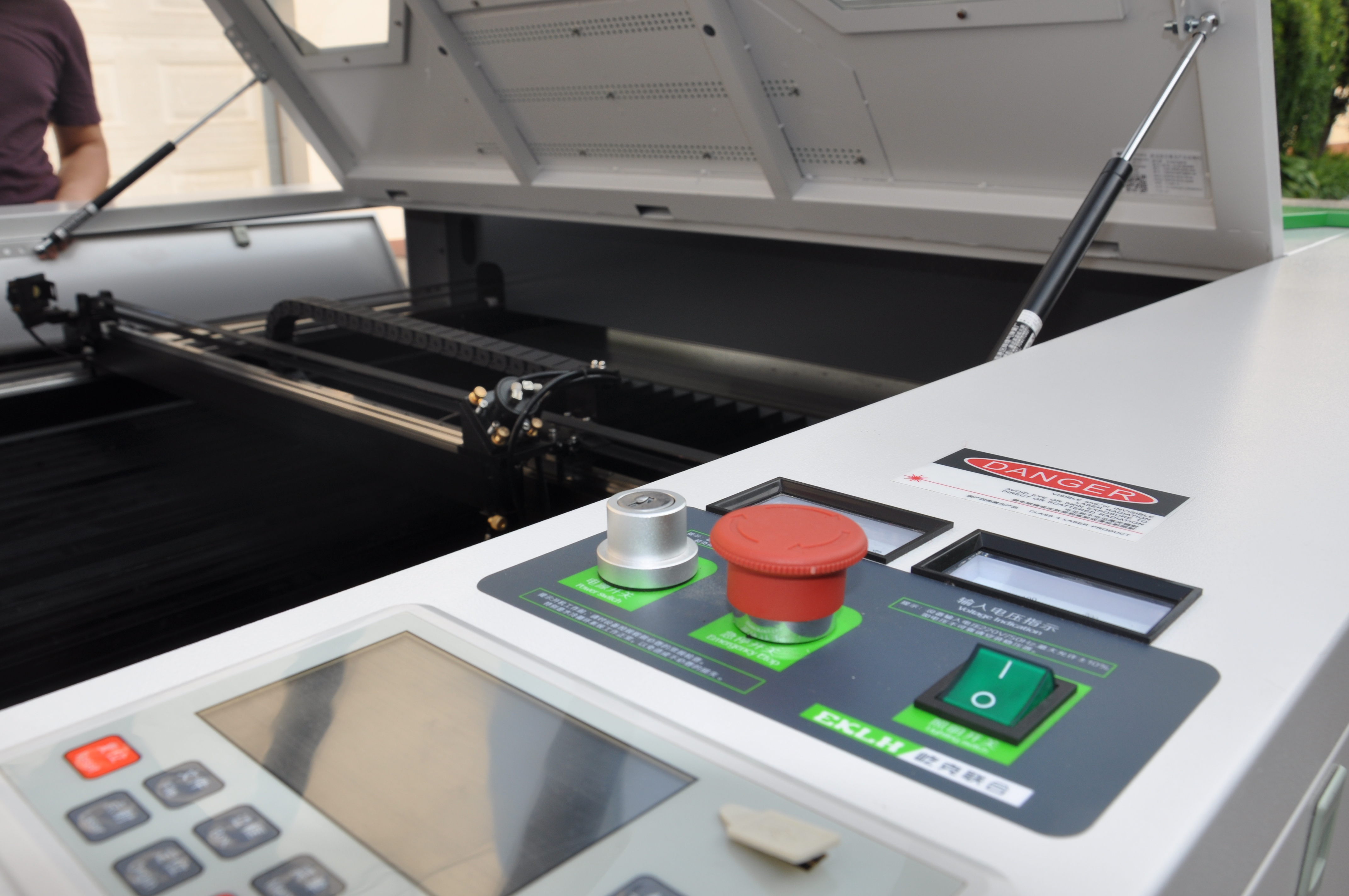

Control system

|

Ruida control system

|

|

Lenses

|

America II VI lenses

|

|

Drive and motor

|

Use leadshine or Syntron three-phase drive and three-phase motor, with high speed, high precision, low noise.

|

|

Transmission system

|

The transmission system adopts three Taiwan PMI square linear guide rail with imported bearing wheel

|

|

Laser tube

|

Standard CDWG H7 laser tube

|

|

Industrial Chiller

|

Industrial Chiller (compression refrigeration)

|

|

CCD

|

Matching CCD positioning edge patrol cutting function (Optional)

|

|

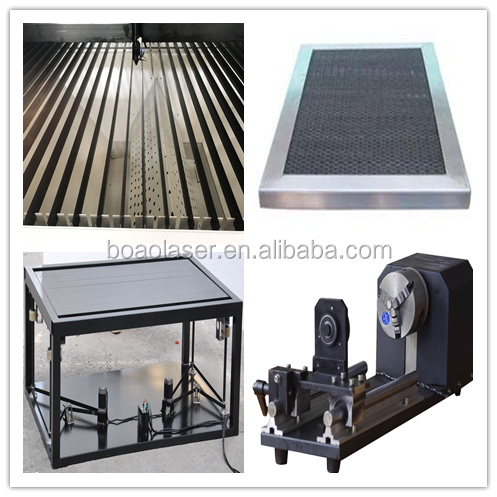

Three different working platform

|

Blade platform, Honeycomb platform or Independent electronic lifting platform(Supply only one platform for standard)

|

|

Rotation auxiliary device(Optional)

|

Used for machining regular cylindrical materials.

|

|

High performance laser power

|

Adopt the new high frequency high voltage switch mode, PWM master control technology, with stable performance, strong anti-interference ability, unique double FBT mode to ensure product stability.

|

|

Unique exhaust system

|

Bigger hole down and small hole up, which can absorb smoke and dust during processing effectively, more environmentally-friendly

|

The equipment is equipped with a full set of accessories to meet the needs of processing :

Title goes here.

Product technical parameters

|

Laser type

|

CO2 sealed laser tube, water-cooled

|

|

Laser power

|

100W(standard),80W/130W/150W/180W/200W can be choosed

|

|

Working area

|

Single head 900*600mm or double head (700*900) *2

|

|

Weight

|

400KGS

|

|

Max. movement speed of machine

|

0-60000mm/min

|

|

Max. working speed

|

0-30000mm/min

|

|

Speed control

|

0-100%

|

|

Laser energy control

|

2 options: Software control/Manual adjustment

|

|

Laser tube cooling

|

Forced water cooling(Industrial chiller)

|

|

Machine resolution

|

0.025mm

|

|

Min. shaping character

|

Chinese 2mm , English 1mm

|

|

Max cutting depth

|

10mm (For Example: acrylic) As to material

|

|

setting positioning accuracy

|

±0.1mm

|

|

Power supply

|

AC220V±15% 50Hz

|

|

Total power

|

≤1500W

|

|

File format supported

|

BMP PLT DST AI DXF DWG

|

|

Driving

|

Stepper motor driving

|

|

setting positioning accuracy

|

0℃~45℃

|

|

Operating humidity

|

5%~95%

|

|

Max scanning accuracy

|

2500DPL

|

|

Carving table

|

Push-pull work platform two options-- honeycomb or blade platform (lifting platform)

|

|

Software language

|

Chinese English and so on

|

Packing&Shipping

We have 3 layers package:

1. Inside layer: the machine is covered by thickening plastic palstic waterproof;

2. Middle: the machine is covered by foam to protect the machine from the shaking;

3. Outside: adopt wood craft case.

Company Introduction

Exhibition features and factory photos

Good service

1. The machine is guaranteed for one year. As consumable—Laser tube is guaranteed according to the arrival time.

2. Provide adequate remote technical services through network communication (voice、text、pictures、video、 ).

3. Provide tutorial videos.

4. Provide overseas technical services (The buyer shall bear travel expenses)

2. Provide adequate remote technical services through network communication (voice、text、pictures、video、 ).

3. Provide tutorial videos.

4. Provide overseas technical services (The buyer shall bear travel expenses)

FAQ for CO2 laser machine

Q: Do I need two laser machine to engrave anf cut seperately?A: No, the laser machines we provise are capable of both engraving

and cutting . One machine alone cnan fulfill the two purposes.

Q: Does the laser machine can connected to a laptop or desktop computer to work?

A: Yes, the machine have professional port to conect computer and also can connected with other machines. It supports Window 2000,

Widdow XP, Window 7, Window 1o and other operating systeIn general ms.

Q: In generally, how long is the service life of a laser tube?

A: Generally, a laser tube's service life can reach 3500 hours to 10000 hours depending on the specific usage. For example, if it

works 8 hours per day, the detailsed data is as following:

1. If you set the power at 20%-30% of the total power, the service life is about 1-2 years.

2. If you set the power at 40%-50% of the total power, the service life is about 1 year.

3. If you set the power at 70%-80% of the total power, the service life is about 6-8 hours.

Q: How can I know the power of a laser tube has been exhausted?

A: The beam color of a new laser tube in operation is purple. When the power is gradually depleted, the color will become white.

Q: Is it better to increase blow to improve laser processing performance?

A: For some thick materials , it works. But, when caving some other materials, you need to blow less.

Q: How long will it take to learn to operate a laser machine?

A: If you are able to use some basic graphic design software, it will only take a few hours to maser the operation. You just need

to do some simple tests on different processing materails to know how to set the correct speed and laser power.

Q: If a laser machine in operation harmful to our bodies?

A: It's not harmful as long as the laser is not exposed directly to skin and eyes.

Q: Do I need two laser machine to engrave anf cut seperately?A: No, the laser machines we provise are capable of both engraving

and cutting . One machine alone cnan fulfill the two purposes.

Q: Does the laser machine can connected to a laptop or desktop computer to work?

A: Yes, the machine have professional port to conect computer and also can connected with other machines. It supports Window 2000,

Widdow XP, Window 7, Window 1o and other operating systeIn general ms.

Q: In generally, how long is the service life of a laser tube?

A: Generally, a laser tube's service life can reach 3500 hours to 10000 hours depending on the specific usage. For example, if it

works 8 hours per day, the detailsed data is as following:

1. If you set the power at 20%-30% of the total power, the service life is about 1-2 years.

2. If you set the power at 40%-50% of the total power, the service life is about 1 year.

3. If you set the power at 70%-80% of the total power, the service life is about 6-8 hours.

Q: How can I know the power of a laser tube has been exhausted?

A: The beam color of a new laser tube in operation is purple. When the power is gradually depleted, the color will become white.

Q: Is it better to increase blow to improve laser processing performance?

A: For some thick materials , it works. But, when caving some other materials, you need to blow less.

Q: How long will it take to learn to operate a laser machine?

A: If you are able to use some basic graphic design software, it will only take a few hours to maser the operation. You just need

to do some simple tests on different processing materails to know how to set the correct speed and laser power.

Q: If a laser machine in operation harmful to our bodies?

A: It's not harmful as long as the laser is not exposed directly to skin and eyes.

Hot Searches