- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

1.6*1.0*0.5m

-

Power (kW):

-

250 kW

-

Weight (KG):

-

6000 KG

-

Name:

-

Tire bead ring cutting machine

-

Color:

-

Blue/green or as your requirements

-

Brand name:

-

HVST

-

Capacity:

-

40pcs/h

-

Advantage:

-

Environmental friendly, energy saving

-

Dimension:

-

40GP or 20 GP container

-

tire range:

-

650-2000mm

-

Package:

-

Wooden boxes or customized

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

HVST

-

Voltage:

-

Customer Request

-

Dimension(L*W*H):

-

1.6*1.0*0.5m

-

Power (kW):

-

250 kW

-

Weight (KG):

-

6000 KG

-

Name:

-

Tire bead ring cutting machine

-

Color:

-

Blue/green or as your requirements

-

Brand name:

-

HVST

-

Capacity:

-

40pcs/h

-

Advantage:

-

Environmental friendly, energy saving

-

Dimension:

-

40GP or 20 GP container

-

tire range:

-

650-2000mm

-

Package:

-

Wooden boxes or customized

Product Description

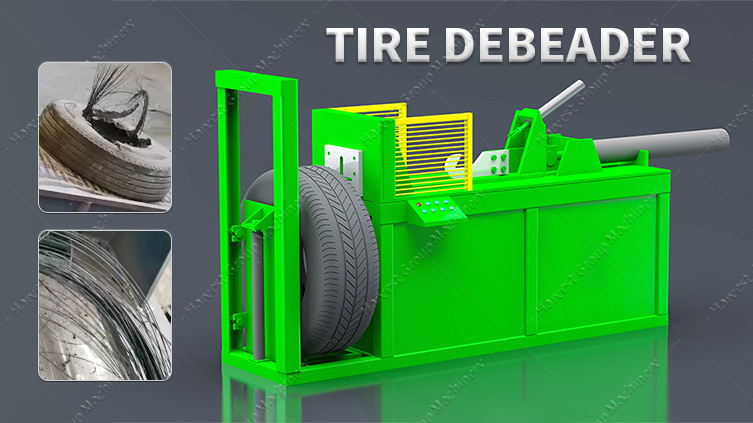

Hydraulic whole tire debeader draw out the wire steels from the tire bead.

Introduction

The tire debeader is composed of motor, hydraulic system, hook and frames. It’s used to draw out the wire rings from the tire rims, which will greatly protect the blade of the tire shredder. Working process: Place the tire at the cross opening, then pass the hook through the cross and grasp the inner ring of the tire, and then start the button to pull out the whole steel rings with the power of oil cylinder, to achieve smooth separation of tires and inner ring. A protective frame is equipped to effectively prevent unsafe factors in the debeading process.

The Flow chart of Tire Recycling Machine

Waste tire recycling machine tire recycling equipment price waste tire recycling plant for sale is used to crush waste tires into rubber blocks, granules and powder in different sizes.

The working process of waste tire recycling rubber powder production line:

Waste tire - Tire de beader- whole tire cutting - tire shredder - Rubber crushing - magnetic separator - fiber separator - Rubber powder

Double roller waste tire recycling crusher machine production line

Flow chart of tire recycling

(Fully-automatic Production Line):

Waste tire - Tire de beader- whole tire cutting - tire shredder - Rubber crushing - magnetic separator - fiber separator - Rubber powder

Flow chart of semi automatic tire recycling line

Whole tire--tire circle cutter--tire strip cutter--tire slice cutter--rubber crusher--Magnetic separator--Nylon fiber separator--rubber powder

Tire circle

to cut open the joint of tire bead and side wall

Tire strip

to cut tire into strip

Tire slice cutter

To cut strip into block

Host equipment,rubber crusher: is used to be grind the chunks into small mesh powder through the vibrating screen as you need.

Machines feature of rubber crusher

1)Roller structure: Our two rollers are both grooved, which increase the friction and then improve the output.

2)Roller material: The roller is made by Welding wear resistant alloy materials, 5Cr6MnMo. We can offer you 3 years warranty of the roller.

3)Crusher roller speed ratio:Roller speed ratio is 1:2.5, high speed and low noise

4)Bearing:there are 8 pieces bearing in the main crusher.

5)9.99% nylon and radial removing rate. keeping the final rubber powder is pure.

Magnetic separator: Separate the wire steel from the powder.

Nylon separator: separate the nylon fiber from the nylon tire

The Flow chart of Tire Recycling Machine

Waste tire recycling machine tire recycling equipment price waste tire recycling plant for sale is used to crush waste tires into rubber blocks, granules and powder in different sizes.

The working process of waste tire recycling rubber powder production line:

Waste tire - Tire circle cutter- tire strip cutter - tire slice cutter - Rubber crushing - magnetic separator - fiber separator - Rubber powder

Q1: Are you a factory or a trading company ?

A1: We are a manufacturer with 30 years production experience in tire recycling plant and nail making machines. We have export license, we can offer you the factory prices.

Q2: Can you guarantee the capacity as you mentioned ?

A2: Definitely yes, the grooved two rollers are specially designed to increase the output and ensure the working efficient.

Q3: are you sure the final rubber powder can be completely clean out of wire steel or nylon ?

A3: The final powder purity can reach 99.9%. we have magnetic separator which can separate the wire steel from the rubber powder.