- Product Details

- {{item.text}}

Quick Details

-

Color:

-

Grey

Quick Details

-

Place of Origin:

-

Shaanxi, China

-

Brand Name:

-

CHINA APS

-

Model Number:

-

JP-1108ST

-

Color:

-

Grey

Products Description

Bis size 540L customized size, Engine Parts Industrial Ultrasonic Cleaner , Fuel Pump Ultrasonic Cleaning Machine-------------Single Tank Series

Features:

1.Stainless steel tank has resistance to wear and long work life

2.Tank capacity: customized, with rinsing tank , drying tank

3. With Stainless steel basket

4.A large variety of different formulas designed for specific applications. Proper selection is crucial for acceptable cleaning activity and to prevent unwanted reactions with the work piece.

5. Industrial control chip microcontroller.flexible circuit boards control, more secure & stable

6.Temperature tunable from 20°C to 80°C

7. With drainage.

|

MODEL:

|

JP-360ST

|

JP-480ST

|

JP-600ST

|

JP-720ST

|

JP-1108ST

|

JP-1144ST

|

|||||

|

Tank Dimension (mm)

|

600*500*450

|

700*500*500

|

800*600*550

|

1000*600*600

|

1000x900x600

|

1200x1000x800

|

|||||

|

Tank total capacity

|

135L

|

175L

|

264L

|

360L

|

540L

|

960L

|

|||||

|

Ultrasonic transducer numbers

|

36pcs

|

48pcs

|

60pcs

|

72pcs

|

108pcs

|

144pcs

|

|||||

|

Ultrasonic power

|

1800W

|

2400W

|

3000W

|

3600W

|

0-5400W

|

7200W

|

|||||

|

Heater’s (Hot Plate) Power

|

4500W

|

6000W

|

6000W

|

9000W

|

18000W

|

27KW

|

|||||

|

Electronic generator

|

2 units KG1800

|

|

|

|

|

4 units KG1800

|

|||||

|

Ultrasonic frequency

|

40KHZ/28KHZ

|

|

|

|

|

|

|||||

|

Housing material

|

Stainless steel

|

|

|

|

|

|

|||||

|

Tank material

|

2MM SUS304

|

|

|

|

|

|

|||||

|

Timer control

|

1S-99H adjustable

|

|

|

|

|

|

|||||

|

Heating Temp

|

20-95C adjustable

|

|

|

|

|

|

|||||

|

Drain

|

1" Valve

|

|

|

|

|

|

|||||

|

Cleaning Tank’s Power requirement

|

AC 380V/415V , 3 ; 50/60Hz

|

|

|

|

|

|

|||||

|

Generator power requirement

|

AC 220V/380V 3phase

|

|

|

|

|

|

|||||

|

Accessory

|

With basket, lid, frame, wheel(with brake)

|

|

|

|

|

|

|||||

|

Optional

|

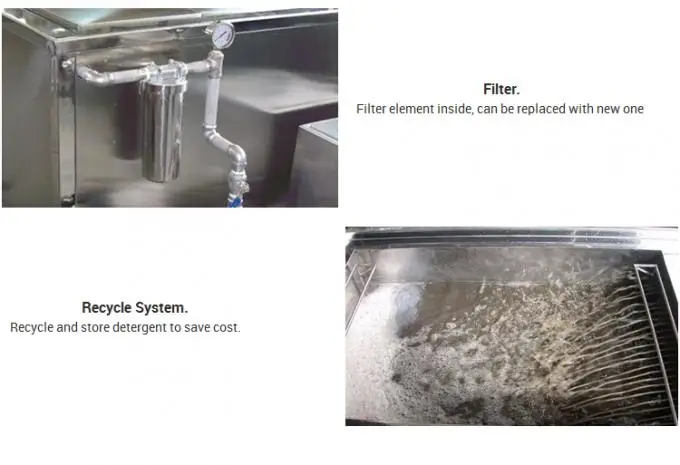

Oil filter system ,Lifting equipment

|

|

|

|

|

|

|||||

ultrasonic equipment for automotive parts radiators Feather

1 quickly and stable cleaning ,low breakdown ,good quality with factory price, professional testing ,quality assurance

2 Powerful transducer and clear circuit,top quality steel made for body, cover and base

3 Digital timer and heating control,Adjustable frequency

4 Stainless steel basket, with 500kgs load weight5 Powerful transducer, clear circuit 6 high-power integrated module

7 High efficiency and keep precision,

8 auto water level control inspection

9 high effective, low costs , PLC control, LCD contact screen

10 cleanness-degree high, The cleanness of consistent, On the surface no damage

11.original German transducer,above 90% output ultrasonic power

12.Quality assure 1 year,provide products as your requirement

Application of Ultrasonic Immersible Transducer

immersible ultrasonic transducers This series of products is suitable to cleaning work pieces of various industries;such as plating components cleaning before plating,electronic,hardware machinery parts,clock and watch parts,semiconductor sillcon chips,glass vessels,bijouterie,spectacle frame, etc.

· Pre-plating cleaning for parts to be plated, oil and dirt removing for metal mechanical. Parts, cleaning semi-conductor Si-chips, spectacle frames and glass vessels.

· Lens, sunglasses, short-sighted mirror and prism, the microscope, camera, glass equipment, etc.

• electroplating accessories, watch & clock accessories, metal accessories, terylene filter core, semiconductor silicon, tools, lens, spectacle frames, jewelry and glass containers...etc.

Ultrasonic Frequency Choices

Ultrasonic operating frequency is perhaps the single most important consideration when choosing an ultrasonic cleaning system. Each frequency has its own unique characteristics. Low frequencies are used for large, un-detailed parts with heavy contamination and produce un-even cleaning action in the fluid, while higher frequencies produce more evenly distributed cleaning action, and have the ability to penetrate small blind holes,

threaded areas, and other detail. More frequency choices 68kHz / 80kHz / 120kHz are available.

Choosing an ultrasonic frequency for a magnetostrictive system is easy, since there really is no choice at all. Magnetostrictive system designs typically operate at frequencies below 30kHz, making these systems unsuitable for most ultrasonic cleaning applications. Most parts being cleaned ultrasonically require the removal of lightly-bonded contaminants on the surface of precision parts, applications which are addressed

with 40kHz, 80kHz orCROSSFIRE Multiple Frequency Ultrasonics operating in this range. Low frequencies would produce in-consistent cleaning results on such parts, and parts may be damaged by cavitational erosion. Although Zenith manufactures 28kHz ultrasonic systems, they are rarely recommended for any ultrasonic cleaning applications, unless they are combined with 40kHz in a CROSSFIRE system. This is the direct result of the thousands of sample parts which have been test-cleaned ultrasonically at Zenith. Our Ultrasonic Testing Service is used to develop complete processes for our potential customers. Parts are submitted and tested in various ultrasonic frequencies and cleaning agents to determine the best process to use for a given application. Low frequency ultrasonic cleaning systems in the 25kHz-30kHz range never produce a better cleaning result than higher frequency systems do. In fact, it is exactly the opposite. Parts are cleaned more effectively in systems operating at 40kHz and above. Since these systems are less damaging to components, quieter in operation, and better at cleaning in fine detailed areas, these systems are usually recommended for any cleaning application.

Hot Searches