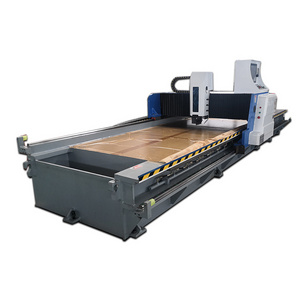

2,This machine beam is fixed,has feeding system,worktable levelness is within

±0.03mm.

3Blade rack move right and left by synchronous belt,V-cutting process is very stable,and the cutting surface is smooth.