- Product Details

- {{item.text}}

Quick Details

-

Power:

-

10KW

-

Dimension(L*W*H):

-

2100*600*2200MM

-

Weight:

-

550 KG

-

Product name:

-

Falling Film Evaporator

-

Capacity:

-

100-1000L/h

-

Material:

-

SS316L Or SS304

-

Function:

-

Remove solvent

-

Certification:

-

CE ,ISO

-

Vacuum degree:

-

0.001 Mbar

-

Evaporation Flask:

-

20L receiving flask

-

Rotor pump:

-

0.6-2.0T/H

-

Sealing:

-

PTFE Vacuum Sealing

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

DOVMX

-

Voltage:

-

220V/50-60HZ

-

Power:

-

10KW

-

Dimension(L*W*H):

-

2100*600*2200MM

-

Weight:

-

550 KG

-

Product name:

-

Falling Film Evaporator

-

Capacity:

-

100-1000L/h

-

Material:

-

SS316L Or SS304

-

Function:

-

Remove solvent

-

Certification:

-

CE ,ISO

-

Vacuum degree:

-

0.001 Mbar

-

Evaporation Flask:

-

20L receiving flask

-

Rotor pump:

-

0.6-2.0T/H

-

Sealing:

-

PTFE Vacuum Sealing

Product Description

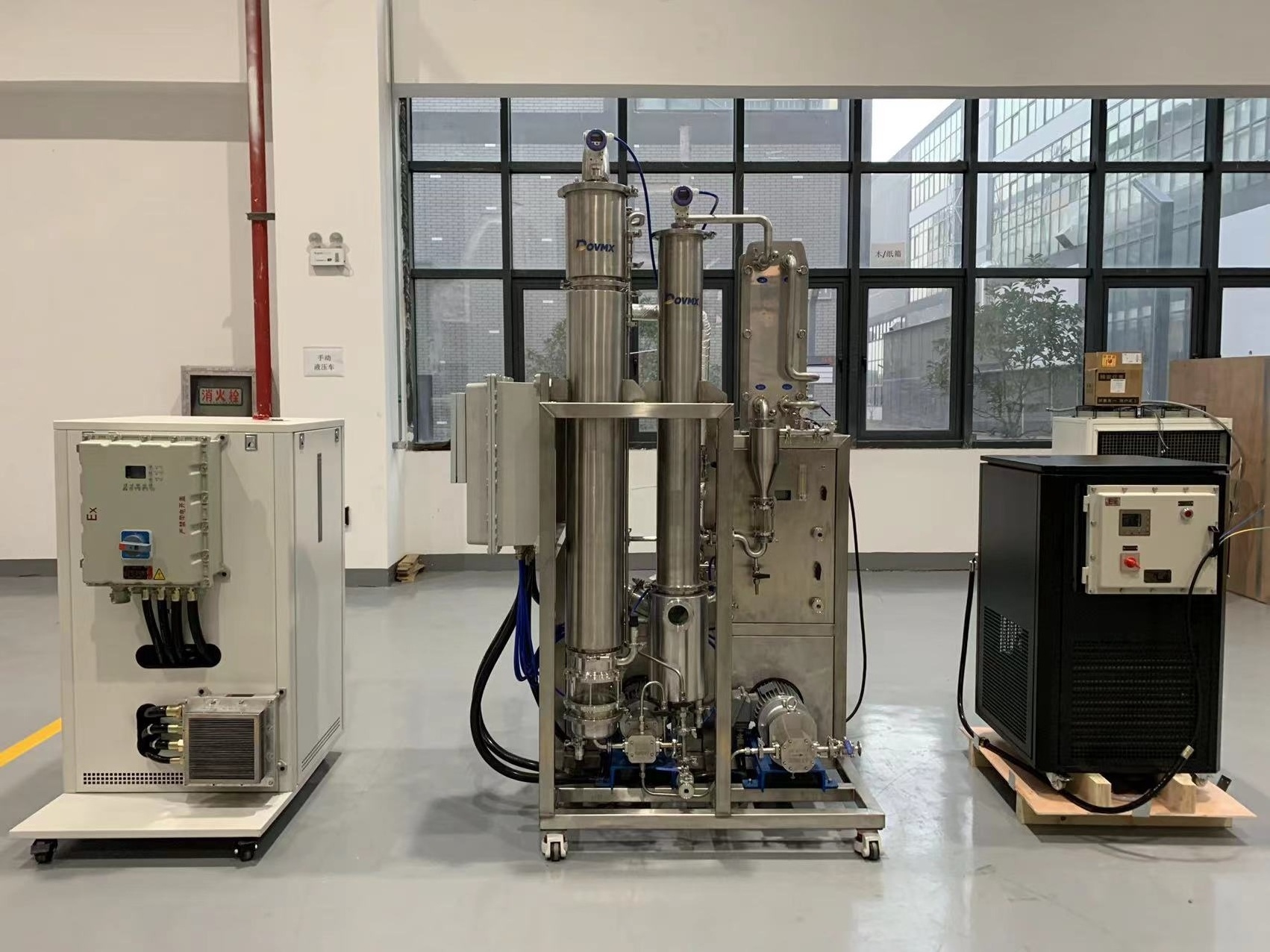

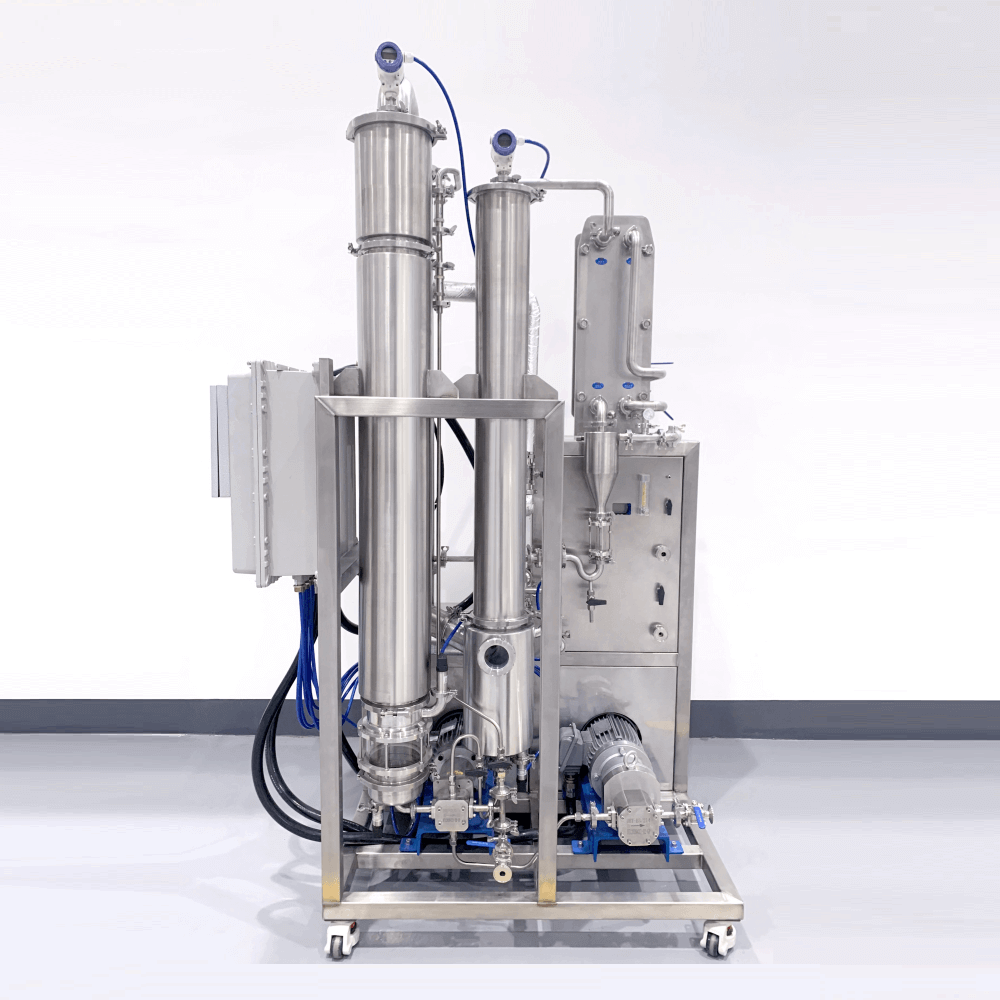

Stainless steel high efficient vacuum 100L/h single effect falling film evaporator for ethanol recovery

Falling film evaporator is widely used for evaporation, concentration and concentration of water or organic solvent solution in food, chemical, light industry and other industries, and can be widely used for waste liquid treatment in the above industries. Especially suitable for heat sensitive materials, the equipment is continuously operated under vacuum and low temperature conditions, with high evaporation capacity, energy saving and consumption reduction, low operating costs, and can ensure the invariability of materials in the evaporation process.

The falling film evaporator includes a heating heat exchanger, which is formed with a feed inlet, and the heating heat exchanger is connected with the top of the integrated falling film evaporator; The bottom of the falling film evaporator is connected with a circulating pump, and the circulating pump is connected with a finished product tank; The heating cavity of the integrated falling film evaporator is communicated with an air inlet pipe and an air outlet pipe, and is communicated with a heater; The air outlet of the integrated falling film evaporator is connected with the heating chamber of the heating heat exchanger, the heating chamber of the heating heat exchanger is connected with the first cooling heat exchanger, the first cooling heat exchanger is connected with the transfer tank through the vacuum pump, the transfer tank is connected with the second cooling heat exchanger, and the second cooling heat exchanger is connected with the alcohol recovery tank.

Features of falling film evaporator

1. Low heating temperature

2. High evaporation speed

3. Short liquid residence time

4. Continuously feeding and discharging

5. Suitable for heat sensitive materials

6. Energy-saving

The materials are evenly distributed on the inner wall of the falling film tube from the top of the falling film chamber through the film distribution device, and flow from top to bottom in the form of a film by its own gravity and secondary steam flow. At the same time, the materials and secondary steam are evaporated by heat exchange with the heating steam on the outer wall of the falling film tube. The evaporated materials and secondary steam enter the separated type for gas-liquid separation. The materials are sent out through the discharge pump. If the material concentration does not meet the requirements, the steam volume is adjusted through the plunger valve, Ensure the concentration of outlet materials. The secondary steam enters the service condenser and is cooled with cooling water. The non condensable gas is sucked out by the vacuum pump, and the system is guaranteed to work under vacuum.

DOVMX automatic falling film evaporator is designed to let the mixed fluid flow down the pipe wall to form a continuous film, so as to uniformly and continuously evaporate. The separation of internally vaporized fluid, liquid (solution) and gas occurs in the pipeline. The system operates under vacuum to allow low temperature separation.

DOVMX falling film evaporator belongs to a movable device. According to the characteristics of CBD extraction, the liquid

inlet and steam are exchanged for heat, so as to save energy, improve the extraction efficiency, facilitate movement and reduce the complexity of operation.

The falling film evaporator includes a heating heat exchanger, which is formed with a feed inlet, and the heating heat exchanger is connected with the top of the integrated falling film evaporator; The bottom of the falling film evaporator is connected with a circulating pump, and the circulating pump is connected with a finished product tank; The heating cavity of the integrated falling film evaporator is communicated with an air inlet pipe and an air outlet pipe, and is communicated with a heater; The air outlet of the integrated falling film evaporator is connected with the heating chamber of the heating heat exchanger, the heating chamber of the heating heat exchanger is connected with the first cooling heat exchanger, the first cooling heat exchanger is connected with the transfer tank through the vacuum pump, the transfer tank is connected with the second cooling heat exchanger, and the second cooling heat exchanger is connected with the alcohol recovery tank.

Features of falling film evaporator

1. Low heating temperature

2. High evaporation speed

3. Short liquid residence time

4. Continuously feeding and discharging

5. Suitable for heat sensitive materials

6. Energy-saving

The materials are evenly distributed on the inner wall of the falling film tube from the top of the falling film chamber through the film distribution device, and flow from top to bottom in the form of a film by its own gravity and secondary steam flow. At the same time, the materials and secondary steam are evaporated by heat exchange with the heating steam on the outer wall of the falling film tube. The evaporated materials and secondary steam enter the separated type for gas-liquid separation. The materials are sent out through the discharge pump. If the material concentration does not meet the requirements, the steam volume is adjusted through the plunger valve, Ensure the concentration of outlet materials. The secondary steam enters the service condenser and is cooled with cooling water. The non condensable gas is sucked out by the vacuum pump, and the system is guaranteed to work under vacuum.

DOVMX automatic falling film evaporator is designed to let the mixed fluid flow down the pipe wall to form a continuous film, so as to uniformly and continuously evaporate. The separation of internally vaporized fluid, liquid (solution) and gas occurs in the pipeline. The system operates under vacuum to allow low temperature separation.

DOVMX falling film evaporator belongs to a movable device. According to the characteristics of CBD extraction, the liquid

inlet and steam are exchanged for heat, so as to save energy, improve the extraction efficiency, facilitate movement and reduce the complexity of operation.

1.Evaporation Temperature:40℃~70℃.

2.Steam Pressure:0~0.3Mpa Cooling Water circulation temperature (In20℃ Out 25℃)

3.Processing Ability:Cloud remove 80-95% alcohol from mixtrue liquid.

4.Machine Material:Contact part all SUS 304/316 stainless steel.

5.Machine Voltage:As customer required.220V 380V 440V 480V

6.Operator quantity required:1~2

7.Heating Method:Steam heating(Recommend)

8.Evaporation Mode:Liquid be film to increase the evaporation area by falling drop.

9.The main features:

The equipment system operates under negative pressure, with continuous feeding and discharging, heating and evaporation time is short, and it is suitable for evaporation and concentration of heat sensitive materials.

The material is evaporated under vacuum in a fully sealed system, and the concentrated liquid is pollution-free.

The top cover of the heater is equipped with quick-opening device for easy cleaning.

The equipment has compact structure, small floor area and simple operation

DOVMX falling film evaporator can recover 97.5% - 99% ethanol.

(One set DOVMX-FFE-100L is equivalent to five sets of 50L rotary evaporator)

vacuum single effect DOVMX falling film evaporator Features:

Processing capacity 100L-1000L/h

Continuous feeding and discharging operation

100% stainless steel construction

1 feed gear pump

2 discharge gear pumps

The powerful water ring vacuum pump is integrated with the circulating cooling system for continuous operation

Optimize heat exchanger process to maximize efficiency and energy efficiency

Good vacuum of the whole system

DOVMX falling film evaporator can recover 97.5% - 99% ethanol.

(One set DOVMX-FFE-100L is equivalent to five sets of 50L rotary evaporator)

vacuum single effect DOVMX falling film evaporator Features:

Processing capacity 100L-1000L/h

Continuous feeding and discharging operation

100% stainless steel construction

1 feed gear pump

2 discharge gear pumps

The powerful water ring vacuum pump is integrated with the circulating cooling system for continuous operation

Optimize heat exchanger process to maximize efficiency and energy efficiency

Good vacuum of the whole system

Specification

|

item

|

value

|

|

Applicable Industries

|

Manufacturing Plant, Food & Beverage Factory, Energy & Mining, Chemical industry, food industry, laboratory, Production workshop

|

|

Showroom Location

|

Canada, United Kingdom

|

|

Video outgoing-inspection

|

Provided

|

|

Machinery Test Report

|

Provided

|

|

Warranty of core components

|

1 Year

|

|

Core Components

|

Engine, Bearing, Gearbox, Motor, Pressure vessel, Gear, Pump

|

|

Condition

|

New

|

|

Power Source

|

Electric

|

|

Process

|

Drum Evaporator

|

|

Place of Origin

|

China

|

|

Brand Name

|

DOVMX

|

|

Voltage

|

220V/50-60HZ

|

|

Power

|

|

|

Dimension(L*W*H)

|

|

|

Weight

|

850KG

|

|

Warranty

|

1 Year

|

|

Key Selling Points

|

Automatic

|

|

|

|

Packing & Delivery

Ordinary installed accessories are fixed with tape paper, fragile glass accessories are packed with shockproof foam and cartons, and the whole equipment is fixed with shockproof foam, wrapped with plastic film and packed in wooden cases. Solid waterproof, moisture-proof and shockproof.

Hot Searches