- Product Details

- {{item.text}}

Quick Details

-

Customized Machine:

-

Yes

-

Air Pressure:

-

0.5-1.0MPA

-

Voltage:

-

AC 220V/50Hz

-

Max. Power of Brazing Machine:

-

20KW

-

Influent temperature:

-

Less than 40℃

-

Power of Main Engine:

-

1.5KW

-

Cooling hydraulic pressure:

-

0.2Mpa

-

Dimension:

-

2100mm*900mm*2100mm

-

Application:

-

Welding

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

None

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Aituo

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support, Field installation, commissioning and training, Field maintenance and repair service, Video technical support

-

Customized Machine:

-

Yes

-

Air Pressure:

-

0.5-1.0MPA

-

Voltage:

-

AC 220V/50Hz

-

Max. Power of Brazing Machine:

-

20KW

-

Influent temperature:

-

Less than 40℃

-

Power of Main Engine:

-

1.5KW

-

Cooling hydraulic pressure:

-

0.2Mpa

-

Dimension:

-

2100mm*900mm*2100mm

-

Application:

-

Welding

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

None

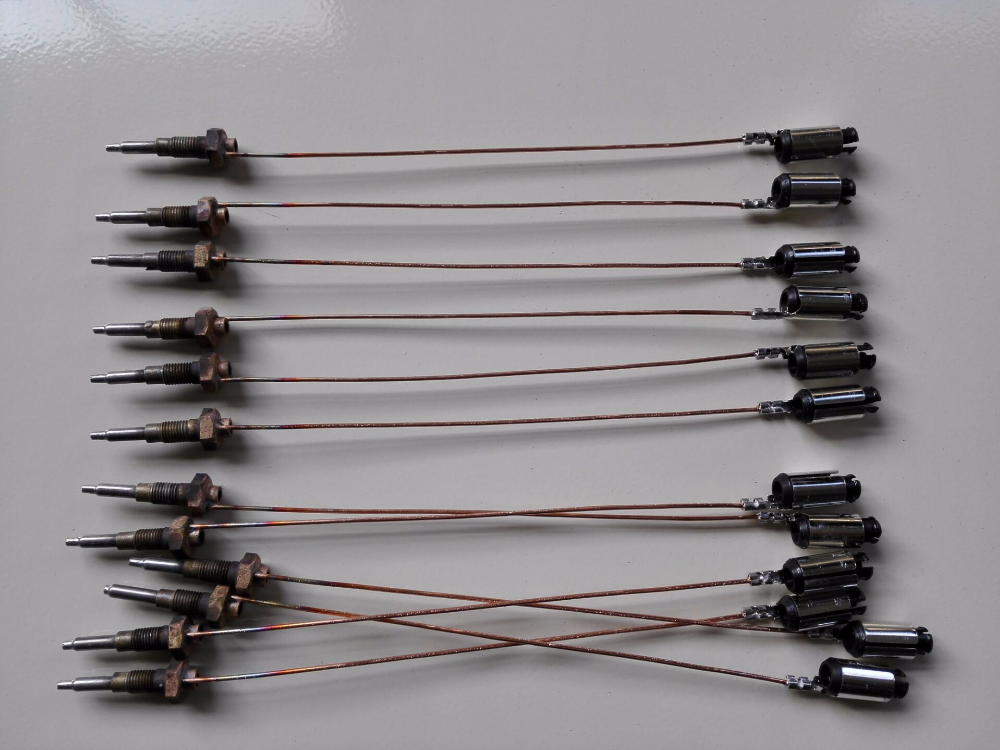

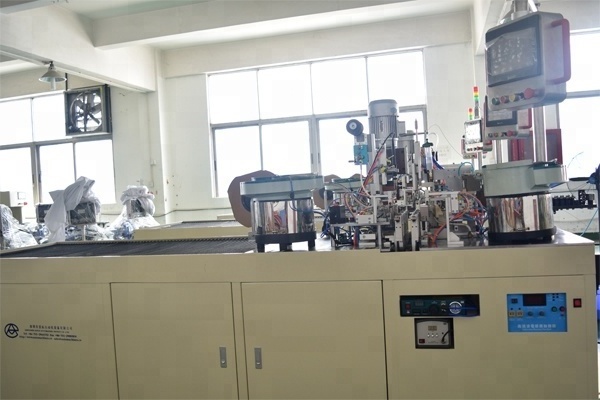

Automatic Brazing Machine is the newest automatic welding machine developed by our company.This machine apply to welding all kinds of copper work pieces.The high frequency brazing technique and robotic arm realize the welding between work pieces. It has advantages of wide range of application, good effect, high efficiency, cost saving and environmental etc.

The induction coil will generate strong alternating magnetic field when induction heating device outputs the electric current flows. Applying a magnetic field, the surface of work piece will generate vortex current and be heated rapidly. The soldering flux and material will be added when the work piece is being heated, the welding processing will finish after the soldering material dissolving and cooling.

Packaging:

All machines we sell will be packed with wood box, covered with steel tie on the surface in order to avoid damaging during

delivery.Before the shipment, we will provide you some pictures of the goods and the package. Or the machine can be packed per your request.

Shipping:

By Sea to the seaport (Door to Seaport service), around 30 days to arrive.

Shenzhen Aituo Automation Device Co., Ltd is a high-tech enterprise focusing on the research, development, production and sales of wire processing equipment and medical product production equipment. The headquarters and R&D base are located in the beautiful Changping jewelry industry Park; The company has strong technical and R&D capabilities, has an experienced technical team with strong R&D capabilities, has a number of patented technologies, and is recognized as a “high-tech enterprise” by the government. Over the years, the company has been adhering to the business philosophy of “Quality First, Integrity and Innovation, and Creating Value for Customers”. With high-quality products and perfect services, the company has won wide recognition from domestic and foreign customers. The main products include: full/semi-automatic ignition pin welding machine, full/semi-automatic thermocouple brazing machine, automatic USB/DC soldering machine, AUX soldering machine, chip/PCB soldering machine, medical pipe extrusion production line, etc., which can be customized by customers demand.

---Purchase guidance

Customized Machine for you

---After Sale Service

Don’t worry, we are here to help. AM provides life time after sale support to our customers including operation guidance, parts replacement, maintenance support. Please feel free to contact us!

--- Technical Support

In some cases, professional technical support will be needed , such as parameter meter set-up for difficult-to process wires. AM engineers are here for your assistance.

---OEM

AM provides OEM services to our customers.