• Enclosed to minimize odors and noise

• Very low wash water usage(1/8 compared with belt press)

• Very low power consumption(1/20 compared with centrifuge)

• High cake solids

• Minimal operator requirement

• Easy to operate and maintain

• Auto start-up, run and shutdown

• Touch screen operation optional

• Sludge Flow and Cake Monitoring System

• Available with many other options like Dairy, Palm Oil, etc.

- Product Details

- {{item.text}}

Quick Details

-

Material:

-

Wooden case

-

Weight:

-

800kg

-

Size:

-

1615*620*1055

-

Power:

-

0.3kw

-

Weight (KG):

-

800 kg

-

Product name:

-

Multi-disk Screw Press

-

Brand:

-

Jorsun

-

Operation:

-

Automatic Running

-

Application:

-

Sludge Dewatering

-

Certification:

-

CE ISO9001

-

Service life:

-

Over 15 years

-

Voltage & flange:

-

Customized

-

Function:

-

Sludge treatment

-

Design:

-

Customized

-

Shipment:

-

20GP, 40HQ, 40FR

Quick Details

-

Marketing Type:

-

Hot Product 2020

-

Place of Origin:

-

Shanghai

-

Brand Name:

-

Jorsun

-

Material:

-

Wooden case

-

Weight:

-

800kg

-

Size:

-

1615*620*1055

-

Power:

-

0.3kw

-

Weight (KG):

-

800 kg

-

Product name:

-

Multi-disk Screw Press

-

Brand:

-

Jorsun

-

Operation:

-

Automatic Running

-

Application:

-

Sludge Dewatering

-

Certification:

-

CE ISO9001

-

Service life:

-

Over 15 years

-

Voltage & flange:

-

Customized

-

Function:

-

Sludge treatment

-

Design:

-

Customized

-

Shipment:

-

20GP, 40HQ, 40FR

Product Overview

JMDS-Multi-disk screw press

Brief Introduction :

Jorsun multi-disk screw press solves the technical problems of previous generations of sludge dehydration equipment, such as easily blocked, unable to deal with low concentration sludge and oily sludge, high energy consumption, complex operation, etc.,and achieves the dehydration goal of high efficiency and energy saving. Under the condition of fully automatic operation, the dehydrator can realize high-efficiency flocculation, continuously complete sludge thickening and pressing dehydration, and finally return or discharge the collected filtrate.

It is widely used in municipal sewage treatment engineering and water treatment system of food, starch, oil, pharmaceutical, chemical, paper, leather and other industries etc.

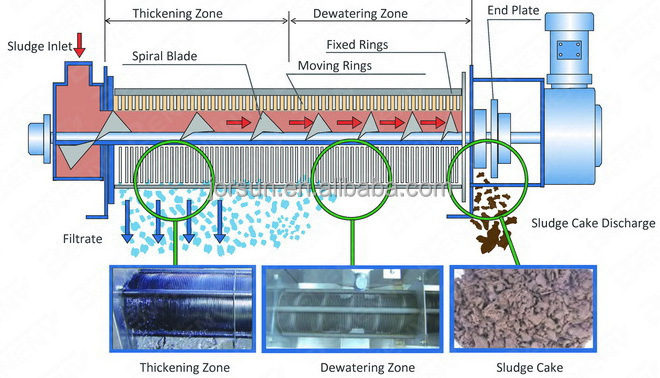

Dewatering Principle

The initial section of dewatering drum is the Thickening Zone, where the solid-liquid separating process takes place and where the filtrate will also be discharged. The pitch of the screw and the gaps between the rings decrease at the end of dewatering drum, hence increasing its internal pressure. At the end, the End Plate further increases the pressure, so as to discharge dry sludge cake.

The initial section of dewatering drum is the Thickening Zone, where the solid-liquid separating process takes place and where the filtrate will also be discharged. The pitch of the screw and the gaps between the rings decrease at the end of dewatering drum, hence increasing its internal pressure. At the end, the End Plate further increases the pressure, so as to discharge dry sludge cake.

FEATURES AT A GLANCE

|

Model

|

DS Standard handing capacity

|

|

Sludge handling capacity(m3/h)

|

|

|

|

|

|

||||||

|

|

Low concentration

|

High conentration

|

2000mg/l

|

4000mg/l

|

10000mg/l

|

20000mg/l

|

25000mg/l

|

50000mg/l

|

||||||

|

101

|

3

|

6

|

1.5

|

0.75

|

0.6

|

0.3

|

0.24

|

0.12

|

||||||

|

131

|

6

|

12

|

3

|

1.5

|

1.2

|

0.6

|

0.48

|

0.24

|

||||||

|

132

|

12

|

24

|

6

|

3

|

2.4

|

1.2

|

0.96

|

0.48

|

||||||

|

201

|

12

|

20

|

6

|

3

|

2

|

1

|

0.8

|

0.4

|

||||||

|

202

|

24

|

40

|

12

|

6

|

4

|

2

|

1.6

|

0.8

|

||||||

|

301

|

30

|

60

|

15

|

7.5

|

6

|

3

|

2.4

|

1.2

|

||||||

|

302

|

60

|

120

|

30

|

15

|

12

|

6

|

4.8

|

2.4

|

||||||

|

303

|

90

|

180

|

45

|

22.5

|

18

|

9

|

7.2

|

3.6

|

||||||

|

351

|

60

|

120

|

30

|

15

|

12

|

6

|

4.8

|

2.4

|

||||||

|

352

|

120

|

240

|

60

|

30

|

24

|

12

|

9.6

|

4.8

|

||||||

|

353

|

180

|

360

|

90

|

45

|

36

|

18

|

14.4

|

7.2

|

||||||

|

354

|

240

|

480

|

120

|

60

|

48

|

24

|

19.2

|

9.6

|

||||||

|

401

|

100

|

170

|

50

|

25

|

47

|

8.5

|

6.8

|

3.4

|

||||||

|

402

|

200

|

340

|

100

|

50

|

34

|

17

|

13.6

|

6.8

|

||||||

|

403

|

300

|

510

|

150

|

75

|

51

|

25.5

|

20.4

|

10.2

|

||||||

|

404

|

400

|

680

|

200

|

100

|

68

|

34

|

27.2

|

13.6

|

||||||

ABOUT JORSUN

·

Jorsun established in Shanghai 2004.

· Jorsun pursues the aim of “focus on separation,service for environment”. Committed to

· Jorsun pursues the aim of “focus on separation,service for environment”. Committed to

separation technology research and development, marketing,equipment manufacturing

and services.

· Jorsun main products and services include: XAF® series DAF, Lamella Clarifier,

· Jorsun main products and services include: XAF® series DAF, Lamella Clarifier,

integrated applications.There are more than 1,000 successful references in the worldwide

over 40 countries till now, such as paper,petrochemical, printing and dyeing,leather,

pharmaceuticals, iron and steel, electronics, food, rivers and community

landscape water

purification, WWTP advanced

treatment and recycled water reuse and some other

industries or fields.

·

Jorsun adheres to the integrity,profession, safety, innovation company value, to meet

customer demands ,has won more extensive customers.

· Jorsun is in pursuit of high quality, continuous innovation,determined to contribute more

· Jorsun is in pursuit of high quality, continuous innovation,determined to contribute more

to environmental protection,become a leader of separation in water fields.

FAQ

Q:How to buy your idea products?

A:You can provide us your water sources, water quality, flow rate and ground area (connect us for more details).

Q:How to pay?

A:TT and L/C are acceptable and TT will be more appreciated. 30% deposit before producing, 70% balance before loading by TT.

Q:What is the delivery time?

A:It depends on order quantities. Generally speaking, the delivery time will be within 4 to 6 weeks.

Q:How to pack the products?

A:We use standard package. If you have special package requirements, we will pack as required, but the fees will be paid by

customers.

Q:How to keep your equipments from corrosion?

A:We use the world-famous paint, like SigmaCoatings,PainBow,etc. What's more, we paint strictly according to the standard process.

Q:How do you manufacture your equipment?

A:Our machining technology includes laser/plasma cutting, automatic welding,CNC cutting and bending.

Q:How to install after the equipments arriving destination?

A:We will provide detailed illustrations to you. If it is necessary, we will send technicians to help you. However, the visa fee,

air tickets, accommodation, wages will be paid by buyers.

A:You can provide us your water sources, water quality, flow rate and ground area (connect us for more details).

Q:How to pay?

A:TT and L/C are acceptable and TT will be more appreciated. 30% deposit before producing, 70% balance before loading by TT.

Q:What is the delivery time?

A:It depends on order quantities. Generally speaking, the delivery time will be within 4 to 6 weeks.

Q:How to pack the products?

A:We use standard package. If you have special package requirements, we will pack as required, but the fees will be paid by

customers.

Q:How to keep your equipments from corrosion?

A:We use the world-famous paint, like SigmaCoatings,PainBow,etc. What's more, we paint strictly according to the standard process.

Q:How do you manufacture your equipment?

A:Our machining technology includes laser/plasma cutting, automatic welding,CNC cutting and bending.

Q:How to install after the equipments arriving destination?

A:We will provide detailed illustrations to you. If it is necessary, we will send technicians to help you. However, the visa fee,

air tickets, accommodation, wages will be paid by buyers.

Hot Searches