- Product Details

- {{item.text}}

Quick Details

-

Core Components:

-

OTHER

Quick Details

-

Place of Origin:

-

SHANDONG

-

Weight (KG):

-

0.4

-

Brand Name:

-

LWEIER

-

Core Components:

-

OTHER

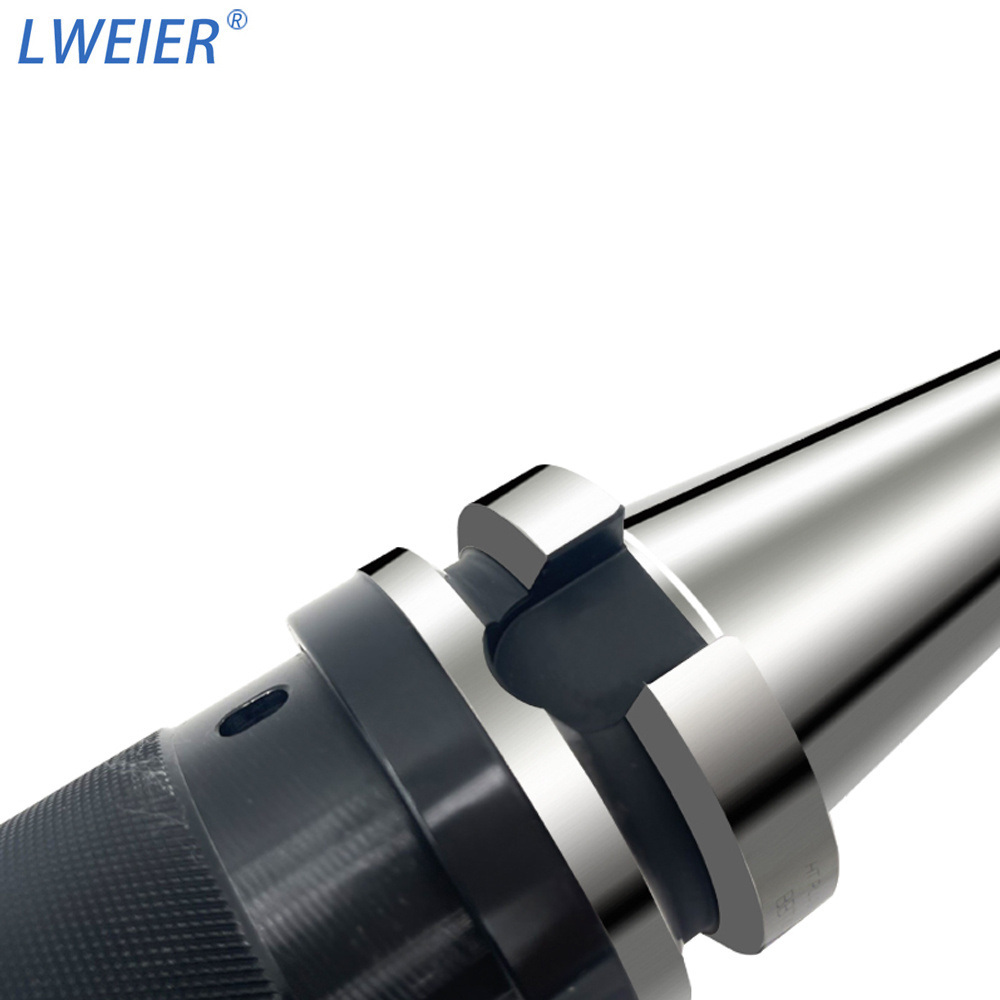

Products Description

Product Features

About this product

1

.

TOTAL FINISHING

:

Strictly control each process to ensure the accuracy of the product. All optical surface, corner arc transition,

bevel process design, effective protection of tool handle, high concen tricity and reduce the friction of the machine.

2. INTEGRATED DESIGN : The integrated design has strong clamping force, efficient processing and heat treatment, high thermal strength

and is not easy to deform and durable. It is suitable for drilling and threading cutting centers/CNC machining centers and is

convenient, stable and more precise.

3.EASY TO INSTALL: Integrated self-drawing chuck tool holder, easy to install and use. Simple structure, convenient loading and

unloading, long service life. International standards, can be selected directly according to the model.

4.SERVICE WARRANTY: If you have any questions about tool holder drill chuck, our 24-hour support team will help you. If we can't

solve your problem, you can contact customer service for replacement.

bevel process design, effective protection of tool handle, high concen tricity and reduce the friction of the machine.

2. INTEGRATED DESIGN : The integrated design has strong clamping force, efficient processing and heat treatment, high thermal strength

and is not easy to deform and durable. It is suitable for drilling and threading cutting centers/CNC machining centers and is

convenient, stable and more precise.

3.EASY TO INSTALL: Integrated self-drawing chuck tool holder, easy to install and use. Simple structure, convenient loading and

unloading, long service life. International standards, can be selected directly according to the model.

4.SERVICE WARRANTY: If you have any questions about tool holder drill chuck, our 24-hour support team will help you. If we can't

solve your problem, you can contact customer service for replacement.

Efficient processing heat trestment

Has high thermal strength and oxygen resistance internal and external steel,not easy to deform durable and long life.

Selected three options to meet different processing needs

High precision black gold style

Alloy three claw

High precision platinum style

Suitable for drilling centers, CNC machining centers, stable clamping, better than ordinary drill chucks, higher accuracy, and

more convenient.

Head changing steps

|

1. Loosen the locking screw inside the pull studs and unscrew it a few times.

|

|

2. Find the M16 screw, screw it in through the pull pin hole, loosen the drill chuck, and then fully unscrew the locking screw.

|

|

3.It is not recommended to knock it out. The thread of the pulling nail hole is M16.

|

|

|

Detail display

Exhibition

Product Paramenters

Correct usage of clamping heads

1. The drill bit needs to be fully inserted to the bottom and cannot be clamped in place.

2. Before use, it must be locked tightly before use, otherwise it may slip and damage the claws.

3. It is prohibited to clamp the milling cutter. The milling cutter is generally subjected to force on the face and side milling, and the drilling chuck cannot withstand the force on the side milling

4. It is prohibited to clamp the reamer. The accuracy of the reamer is required to be high, and sometimes it needs to be expanded and ground, resulting in side stress. The drill chuck cannot achieve high accuracy and cannot withstand stress measurement.

5. It is prohibited to clamp the tap or polygonal handle position. The drill chuck can only clamp the circular handle and vertically processed cutting tools. If the force is not uniform, the claws are easily damaged.

Certifications

Transportation and Packaging

Handels beding ungen

1.Vorlaufzeit:innerhalb von 30 Tagen,Proben innerhalb 7 Tage.

2.Zahlung:T/T,L/C,western union

3.There is a certain discount for bulk purchases

versand

7 Tage lagernd,viele innerhalb von 30 tagen

* Customized non-standard products require negotiation

FAQ

Q: Are you a manufacturer? Do you have a factory?

A: We are professional manufacturers with more than 15 years of experience in the field of cutting tools.5 year of tungsten carbide export business. We have three sales stores in China, can provide you with one-stop shopping, meanwhile we have an excellent and professional sales team, we have strict desire on the quality of the carbide tools

.

Q: Delivery time?

A: Usually the exchange time is 3-5 days after receiving the advance payment. For customized products, 15-20 days after receiving the advance payment.

Q: How long can I expect to get the sample?

A: fter you pay the sample charge and send us confirmed files, the samples will be ready for delivery in 3-7 days. The samples will be sent to you via express and arrive in 3-5 workdays.

Q: what can you buy from us?

A: Carbide End Mills, Carbide Drills, Carbide Inserts, Carbide Thread Mills, Carbide Custom Tools, CNC Tool holders, CNC Cutter Heads, CNC Tools, etc..

Q: What's your delivery method?

A: Express, DHL, TNT, FEDEX, EMS, air and sea can be provided according to your requirements.

Q: Do you offer OEM?

A: Yes, we do.

Q: Do you produce special carbide tools?

A: We can, we can customize it according to your drawings and samples.

Q: What are your payment terms?

A: T/T30% as a down payment and 70% delivery time. Before you pay, we will show you pictures of the product and packaging.

Hot Searches