To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services

will be provided.

- Product Details

- {{item.text}}

Quick Details

-

Hardness:

-

Mid Hard

-

Place of Origin:

-

Shandong, China

-

Length:

-

any

-

Grade:

-

DX51D, G250/G350/G550/DX51D/DX52D/DX53D

-

RAL Color:

-

Ral color

-

Product Name:

-

PPGI Coil

-

MOQ:

-

25Tons

-

Color:

-

RALColor

-

Surface:

-

Color Coated Steel Coil Ppgi

-

Keyword:

-

PPGI Coil Prepainted Steel Coil

-

Sample:

-

Avialable

-

Shape:

-

Coil Roll

-

Technique:

-

Hot Rolled

-

Surface Treatment:

-

Color Coating

Quick Details

-

Type:

-

Steel Coil

-

Thickness:

-

0.21-0.50mm

-

Coating:

-

Z121-Z180

-

Hardness:

-

Mid Hard

-

Place of Origin:

-

Shandong, China

-

Length:

-

any

-

Grade:

-

DX51D, G250/G350/G550/DX51D/DX52D/DX53D

-

RAL Color:

-

Ral color

-

Product Name:

-

PPGI Coil

-

MOQ:

-

25Tons

-

Color:

-

RALColor

-

Surface:

-

Color Coated Steel Coil Ppgi

-

Keyword:

-

PPGI Coil Prepainted Steel Coil

-

Sample:

-

Avialable

-

Shape:

-

Coil Roll

-

Technique:

-

Hot Rolled

-

Surface Treatment:

-

Color Coating

Product Description

The galvanized color-coated coil is to prevent the surface of the steel plate from corroding to prolong its service life, and a

layer of metal zinc is plated on the surface of the steel plate.

According to production and processing methods, it can be divided into 1) Hot dip galvanized steel coil. The sheet is in the

molten zinc bath with a layer of zinc flakes attached to its surface. At present, the continuous galvanizing process is mainly

used, that is, the steel plate is continuously rolled in the melt galvanizing tank made of galvanized steel plate; (2) Alloying of

galvanized steel. This kind of steel coil is made by hot dip method, but after grooving, it is heated to a temperature of about

500 ℃ immediately to form a zinc-iron alloy film. This galvanized sheet has good coating and weldability;

layer of metal zinc is plated on the surface of the steel plate.

According to production and processing methods, it can be divided into 1) Hot dip galvanized steel coil. The sheet is in the

molten zinc bath with a layer of zinc flakes attached to its surface. At present, the continuous galvanizing process is mainly

used, that is, the steel plate is continuously rolled in the melt galvanizing tank made of galvanized steel plate; (2) Alloying of

galvanized steel. This kind of steel coil is made by hot dip method, but after grooving, it is heated to a temperature of about

500 ℃ immediately to form a zinc-iron alloy film. This galvanized sheet has good coating and weldability;

Pretreatment (including chemical degreasing and chemical conversion treatment)

, and then coated with a layer or multilayer

organic coating, the substrate used for the pre-coated steel plate by GI Steel coils, GL steel coils and then baked and cured

after the formation of products. Topcoat can be divided into polyester, silicone modified polyester, high durability of polyester

(HDP), polyvinylidene fluoride (PVDF). In addition, we can also produce with PPGI/PPGL protective film, PPGI/PPGL printing steel,

PPGI/PPGL matte steel, such as the pre-coated steel. Prefabricated steel is widely used in construction, home appliances and

furniture

organic coating, the substrate used for the pre-coated steel plate by GI Steel coils, GL steel coils and then baked and cured

after the formation of products. Topcoat can be divided into polyester, silicone modified polyester, high durability of polyester

(HDP), polyvinylidene fluoride (PVDF). In addition, we can also produce with PPGI/PPGL protective film, PPGI/PPGL printing steel,

PPGI/PPGL matte steel, such as the pre-coated steel. Prefabricated steel is widely used in construction, home appliances and

furniture

Specification

|

Thickness

|

0.13-1.0mm,Thickness tolerance:±0.02mm

|

|

Width

|

Less than750mm-1250mm,Width tolerance:-0/+3mm

|

|

Coil weight

|

3-6MT

|

|

Coil ID/OD

|

Coil ID:508±10mm ; Coil OD: 900-1200 mm

|

|

Paint Coating

|

15-25um

|

|

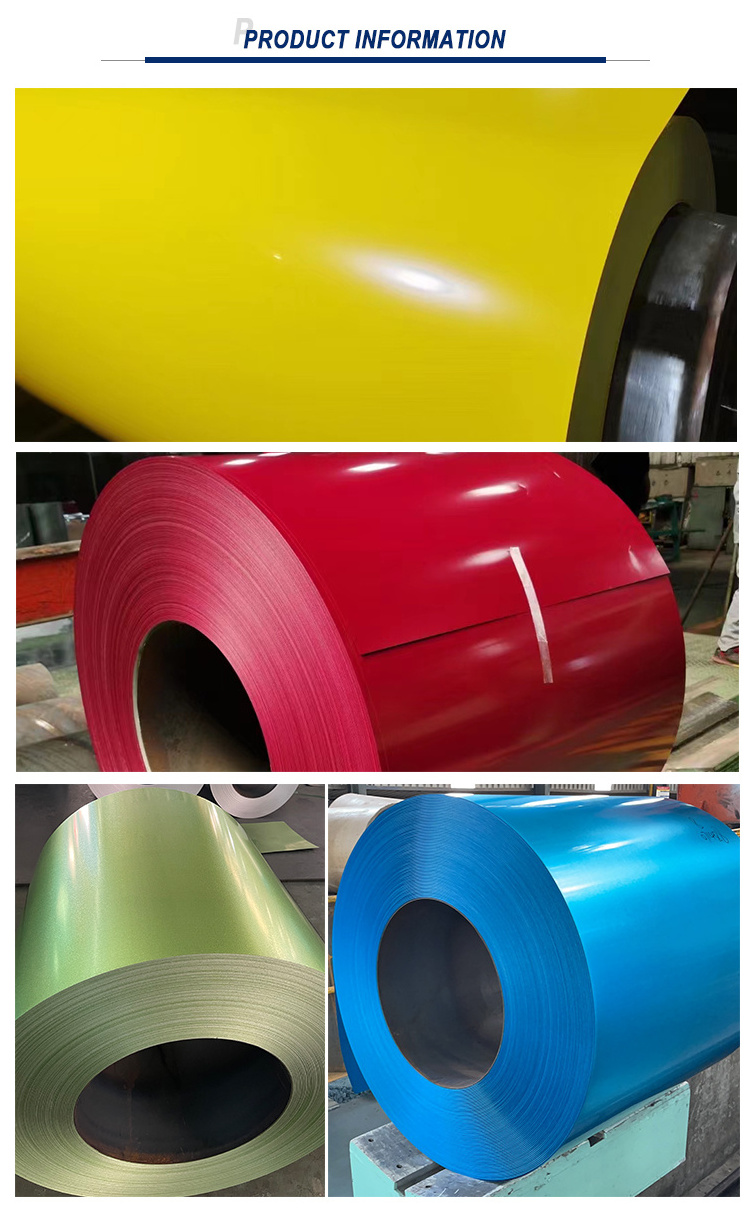

Colors

|

refer to RAL numbers or customer sample,common colors are sea blue, white grey and bright red.

|

|

Surface

|

top coating:10-25um;back coating :5-10 um

|

|

Gloss

|

The gloss can changeable by Customers' Request.we can also do some High gloss, with some sparkling granule in it.

|

|

Paint type

|

PE or PVDF

|

|

Standard

|

GB/T 12754-2006;ASTM A 755;EN 10169;JIS G 3312;AISI;BS;DIN

|

|

Grade

|

CGCC/SGCC/SGCH/SPCC

|

|

application:

|

1.Electrical appliance:

Central heating slice, lampshade, desk, bed, locker, bookshelf. 2.Workshop, agricultural warehouse, residential precast unit, corrugated roof, roller shutter door, rainwater drainage pipe, retailer booth 3.Carrying trade: Writing panel, garbage can, billboard, timekeeper, typewriter, 4.Furniture: exterior decoration of auto and train, clapboard, container, 5.Others : writing panel , garbage can , billboard , timekeeper , typewriter , instrument , panel , weight sensor , photographic equipment . |

Packing & Delivery

Packages

Application

1. Construction field: Color-coated steel coils are widely used in building roofs, wall panels, doors and windows, roof trusses, partition walls and ceilings. Color-coated steel coils not only have aesthetic properties, but also have good waterproof, fireproof and heat-insulating properties. They are an excellent building material.

2. Home appliance field: Color-coated steel coils are widely used to make home appliance casings, such as refrigerators, air conditioners, washing machines, microwave ovens, and electric ovens. Color-coated steel coils are wear-resistant, anti-corrosive, easy to clean and beautiful, and can meet the appearance and performance requirements of the home appliance industry.

3. Transportation field: Color-coated steel coils can be used to make body shells, roofs, chassis, frames and other components. Color-coated steel coils are lightweight, high-strength, corrosion-resistant, wear-resistant and beautiful, and can improve the safety and aesthetics of transportation vehicles.

4. Furniture field: Color-coated steel coils can be used to make office furniture, kitchen furniture, bookshelves, wardrobes and other furniture. Color-coated steel coils are beautiful, wear-resistant, easy to clean and corrosion-resistant, and can meet the requirements of the furniture industry for material appearance and performance.

5. Electronic equipment field: Color-coated steel coils can be used to make electronic equipment casings such as TV casings, audio casings, and computer casings. Color-coated steel coils have the characteristics of beautiful appearance, wear resistance, corrosion resistance and electromagnetic interference resistance, which can improve the safety and aesthetics of electronic equipment.

Hot Searches