- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

Nickel chrome 80/20

-

Shape:

-

plate

-

Material:

-

ni cr alloy

-

Chemical Composition:

-

Ni,Cr, etc.

-

Using:

-

Nickel chrome 80/20 Nichrome sheet/plate

-

Certificate:

-

ISO9001 & ROHS&BV

-

Highest temperature:

-

above 1000 ℃

-

Melting point:

-

1380~1400 ℃

-

Finish:

-

oxidation

-

Model Number::

-

Nickel chrome 80/20

-

Conductor Material:

-

Nickel chrome 80/20 Nichrome sheet/plate

-

Conductor Type:

-

Other

Quick Details

-

Application:

-

flat irons, ironing machines, Heating,making electric heating elements

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Phoenix

-

Model Number:

-

Nickel chrome 80/20

-

Shape:

-

plate

-

Material:

-

ni cr alloy

-

Chemical Composition:

-

Ni,Cr, etc.

-

Using:

-

Nickel chrome 80/20 Nichrome sheet/plate

-

Certificate:

-

ISO9001 & ROHS&BV

-

Highest temperature:

-

above 1000 ℃

-

Melting point:

-

1380~1400 ℃

-

Finish:

-

oxidation

-

Model Number::

-

Nickel chrome 80/20

-

Conductor Material:

-

Nickel chrome 80/20 Nichrome sheet/plate

-

Conductor Type:

-

Other

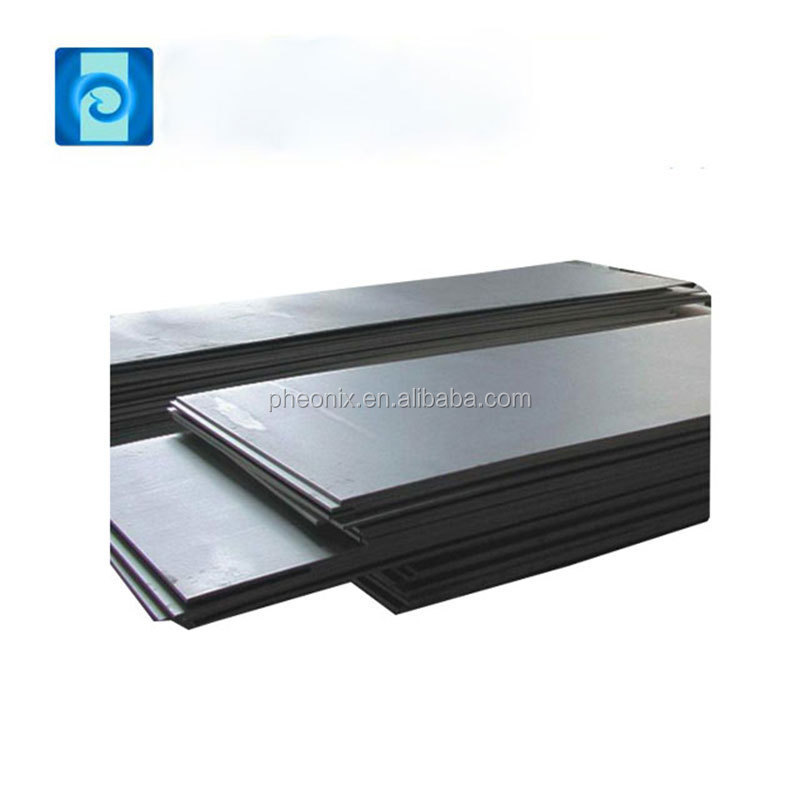

Nickel chrome 80/20 Nichrome sheet/plate

Nickel chrome 80/20 are characterized by high resistivity, good oxidation resistance and very good form stability. They have good ductility after using and excellent weldability.

Nickel chrome 80/20 are used for making electric heating elements in home appliances and industrial furnaces. Typical applications are flat irons, ironing machines, water heaters, plastic moulding dies, soldering irons, metal sheathed tubular elements and cartridge elements.

|

Grade |

Ni80Cr20 |

|

|

Properties |

||

|

Chemical composition % |

Ni |

Balance |

|

Cr |

20.0~23.0 |

|

|

Fe |

≤1.0 |

|

|

Highest service temperature °C |

1200 |

|

|

Melting point °C |

1400 |

|

|

Density g/cm3 |

8.40 |

|

|

Resistivity μΩ.m,20°C |

1.09 |

|

|

Elongation % |

≥20 |

|

|

Specific heat J/g.°C |

0.440 |

|

|

Thermal conductivityKJ/m.h.°C |

60.3 |

|

|

Coefficient of linear extensibility α×10-6/°C |

18.0 |

|

|

Microstructure |

Austenite |

|

|

Magnetic property |

nonmagnetic |

|

Our Advantages

Our Advantages

1 Leading manufacturer of nickel based alloy.

2 Over 20 years experience.

3 Effective and strong technical support.

4 Complete set of quality control system.

5 Professional R&D team and QA&QC inspectors.

6 12 National patents.

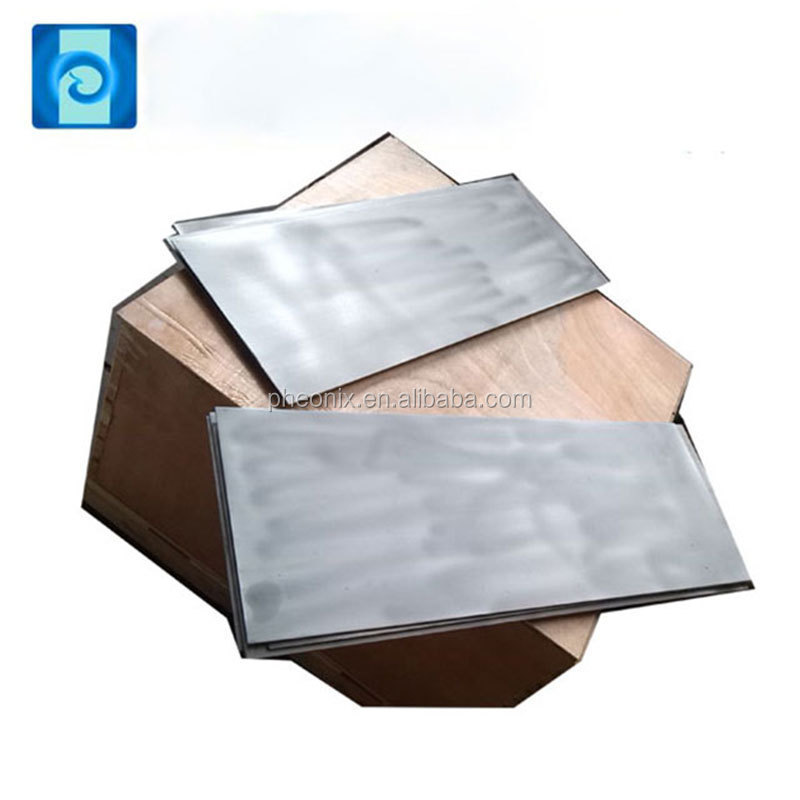

1.Packing

Standard export packing, carton with plywood case for safety

Wire: below dia 1.0mm, packed in spool; Above 1.0mm, packed in coil

Strip, Bar & Tube, Sheet: Packed in Nylon Polybag first

Welding wire: TIG, 5KGS / box, MIG, 15kgs /spool

The goods can be packed as the clients demand.

2.Delivery time:

We can do the order 45-50days upon receive the 30% deposit or L/C document .