- Product Details

- {{item.text}}

Quick Details

-

Marketing Type:

-

New Product 2023

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

CapsulCN

-

Voltage:

-

220V50HZ/110V60HZ

-

Dimension(L*W*H):

-

1600*1600*1600mm

-

Weight (KG):

-

620

-

Power (kW):

-

1.2

-

Model:

-

CED-8

-

Product name:

-

Automatic Electronic Counting Machine

-

Application:

-

Food Chemical Industry

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Operation:

-

Automatic Operation

-

Material:

-

Staninless Steel

-

Size of Bottle:

-

15-300ML

-

Certificate:

-

CE ISO

-

Keyword:

-

Electronic Bottle Counting Machine

-

Function:

-

Counting Bottling

Quick Details

-

Capacity (bottle/min):

-

30 - 50 bottle/min

-

Bottle Capacity (pcs/bottle):

-

1 - 99999 pcs/bottle

-

Capacity (pcs/h):

-

9999 pcs/h

-

Marketing Type:

-

New Product 2023

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

CapsulCN

-

Voltage:

-

220V50HZ/110V60HZ

-

Dimension(L*W*H):

-

1600*1600*1600mm

-

Weight (KG):

-

620

-

Power (kW):

-

1.2

-

Model:

-

CED-8

-

Product name:

-

Automatic Electronic Counting Machine

-

Application:

-

Food Chemical Industry

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Operation:

-

Automatic Operation

-

Material:

-

Staninless Steel

-

Size of Bottle:

-

15-300ML

-

Certificate:

-

CE ISO

-

Keyword:

-

Electronic Bottle Counting Machine

-

Function:

-

Counting Bottling

|

Model

|

CED-8

|

CED-16

(

TO BUY

)

|

||

|

Rate of production

|

10-30 bottles/min

|

10-70 bottles/min

|

||

|

(

Related to material variety, size, bottle specifications, and bottled volume

)

Please contact us for details

.

|

|

|

||

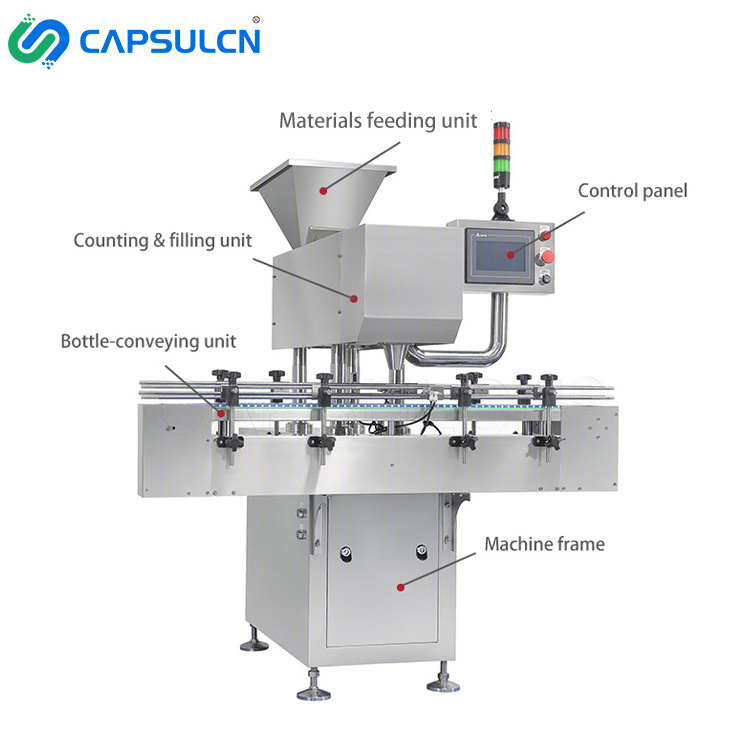

Product Description

8 Channels Automatic Sustainable Vibration Counting Machine

Electronic Counting Machine is mainly suitable for medicine, industry, chemical industry, food and other industries. This machine can be used independently, and can also form a linked production line with other supporting equipment such as

bottle unscrambler

,

paper stopper

,

capping machine

,

sealing

and

labeling machine

.

Main features

①

Three-stage vibrators

:With 8-channel vibration, materials are distributed more evenly.

②

Reliable operation

:It runs stably and smoothly with low noise.

③

High dust resistance

:It adopts unique anti-dust photoelectric sensor.

④

Accurate counting

:Due to photoelectric sensor detection and imported large PLC counting, bottle-filling error meets the international standard.

⑤

Optional function

:If special components are added, it can possess functions such as rejecting unqualified

materials

and photoelectric detection alarming for lack of bottles or bottles being blocked.

⑥

Simple operation

:With intelligent design, various operating parameters can be set in advance, including at most 15 sets in memory.

⑦

Easy maintenance

:The operator only requires simple training as the disassemble, cleaning and replacement of parts are easy to carry out without the need of tools.

⑧

Sealed and dustproof

:It is equipped with a dust box to reduce dust pollution.

⑨

The platform height can be adjusted according to the bottle height.

⑩

The machine is equipped with a power supply voltage stabilizing system, so it can still work normally in areas with unstable power supply.

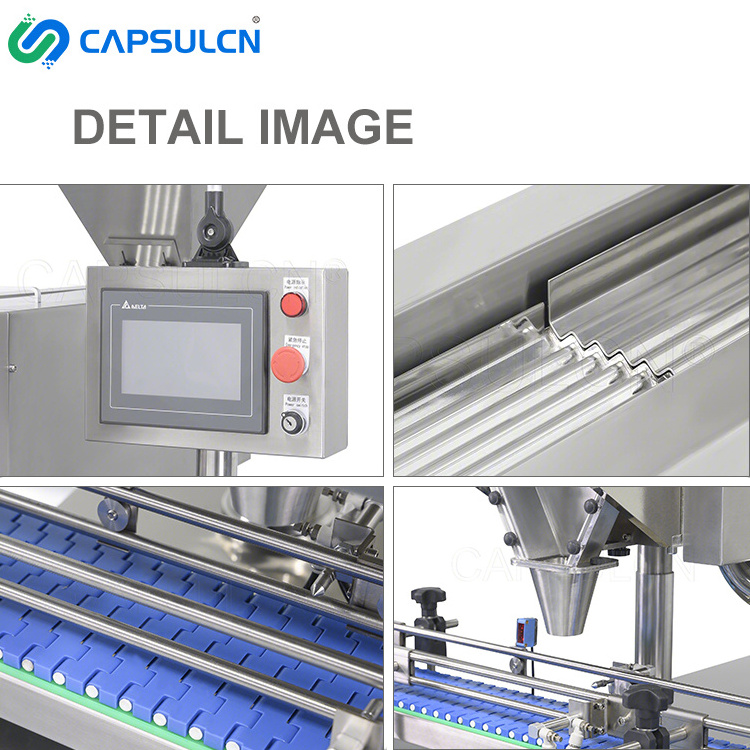

Details Images

Multi-channel vibration channel

According to different models, different specifications, viscous materials are separated and sorted, the vibration frequency can be adjusted, and the noise is low.

Customize the feeding port according to the bottle mouth

Smart "no bottle, no count";Automatic detection function.

PLC control panel

Various parameters and measurements can be set according to requirements, and the interface is simple and easy to operate.

Materials

feeding unit

Three-stage vibrators

Counting & filling unit

Bottle-conveying unit

Electrical control system

Discharge port/outlet height adjustment device

Supporting machines:C

ounting bottling production line

Why Choose Us

Pre-sale service

1.

Support product customization

, any requirements you need can be customized according to your requirements.

2. Sample test on our machine.

3. Provide business consulting and technical support, as well as a free professional packaging solution.

4. Make a machine layout for customers based on customers' factories.

After-sales service

1. Manual book.

2. Videos of installation, adjusting, setting, and maintenance, are available for you.

3. Online support, or face-to-face online communications, are available.

4.

The engineer overseas services

, are available. The tickets, visa, traffic, living, and eating, are for customers.

5. During the warranty year, without human-being broken, we will replace a new one for you.

Recommend Products

Hot Searches