- Product Details

- {{item.text}}

Quick Details

-

Table Travel (Z) (mm):

-

2000

-

Marketing Type:

-

New Product 2023

-

Cutting Accuracy(mm):

-

0.02

-

Brand Name:

-

TOPRESS

-

Voltage:

-

380V/220V

-

Rated Power:

-

37KW

-

Dimension(L*W*H):

-

3000x2000x2000

-

Year:

-

2023

-

Weight (KG):

-

4400 KG

-

Name:

-

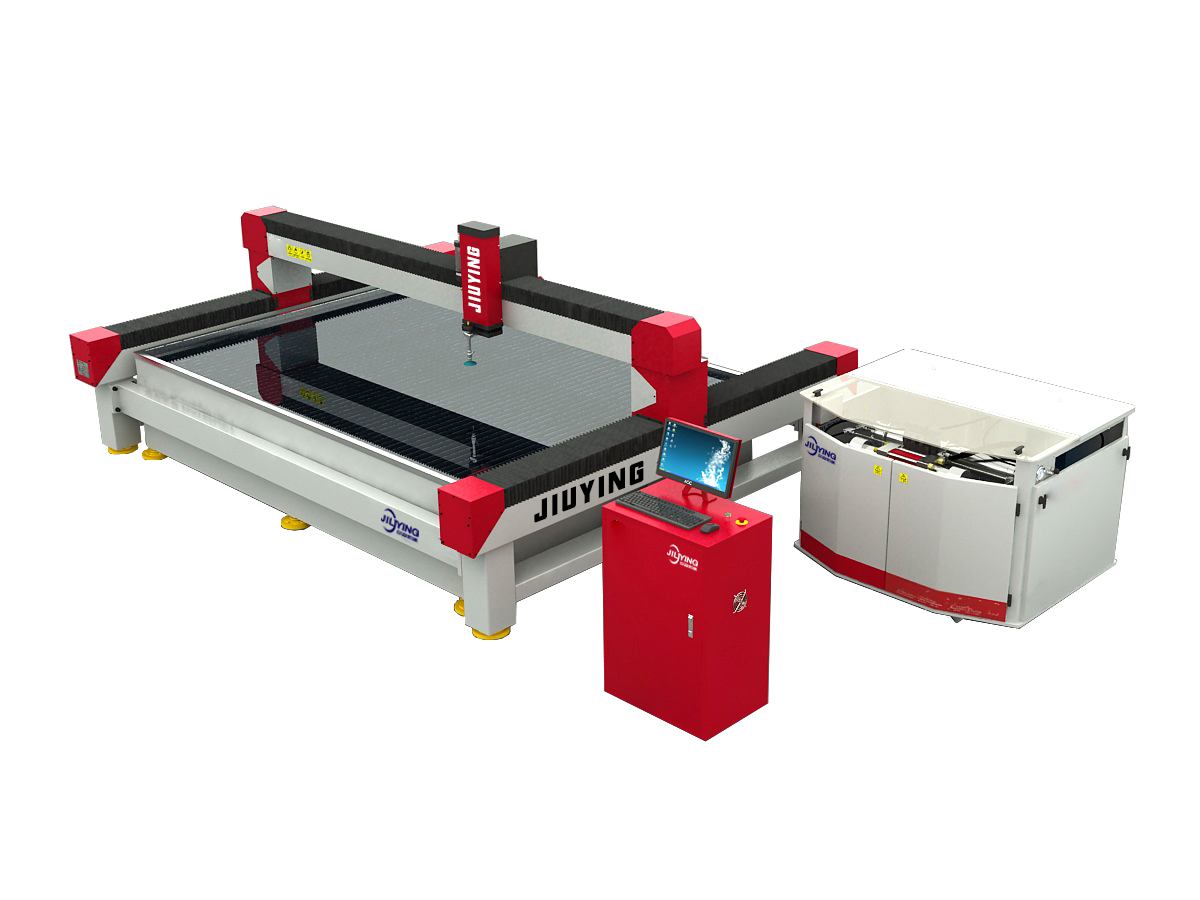

CNC Water Jet Cutting Machine

-

Application:

-

Industrial Metal Cutting

-

After-sales Service Provided:

-

Engineers

-

Type:

-

Water Cutting

-

Cutting material:

-

Stone.etc

-

Cutting mode:

-

Water Cold Cutting

-

Function:

-

High Pressure Water Cutting

-

Control system:

-

CNC Controller

-

Item:

-

Water Jet Cutting Machine-001

-

Model:

-

JYWJ-2060

Quick Details

-

Place of Origin:

-

Liaoning, China

-

Table Travel (X) (mm):

-

3000

-

Table Travel (Y) (mm):

-

2000

-

Table Travel (Z) (mm):

-

2000

-

Marketing Type:

-

New Product 2023

-

Cutting Accuracy(mm):

-

0.02

-

Brand Name:

-

TOPRESS

-

Voltage:

-

380V/220V

-

Rated Power:

-

37KW

-

Dimension(L*W*H):

-

3000x2000x2000

-

Year:

-

2023

-

Weight (KG):

-

4400 KG

-

Name:

-

CNC Water Jet Cutting Machine

-

Application:

-

Industrial Metal Cutting

-

After-sales Service Provided:

-

Engineers

-

Type:

-

Water Cutting

-

Cutting material:

-

Stone.etc

-

Cutting mode:

-

Water Cold Cutting

-

Function:

-

High Pressure Water Cutting

-

Control system:

-

CNC Controller

-

Item:

-

Water Jet Cutting Machine-001

-

Model:

-

JYWJ-2060

Product description

Waterjet Cutting Machine Details

Experience precision and power with our advanced waterjet cutting machines. Renowned for reliability and high performance, our machines ensure exceptional quality for all your cutting needs. Fast delivery and robust support make them the ideal choice for your business.

Experience precision and power with our advanced waterjet cutting machines. Renowned for reliability and high performance, our machines ensure exceptional quality for all your cutting needs. Fast delivery and robust support make them the ideal choice for your business.

CANTILEVER WATER JET CUTTING MACHINE

Standard cantilever water cutting platform, the cutting platform adopts split cantilever design. The Y-axis side frame is made of welded concrete, which has a stable structure. The X-axis adopts one-time extruded 8mm aluminum alloy, which is light in weight and high in rigidity, and the weight is only half of that of traditional materials. Cantilever water jet cutting machine space for loading and unloading is large, and it can be loaded and unloaded from three sides, which is easy to operate and occupies a small area.

GANTRY WATER JET CUTTING MACHINE

Gantry water jet cutting machine is currently applicable to the most material cutting process; A wide range of cutting materials (metal, glass, stone, composite materials, etc.) Cold cutting, no thermal effect, no need for secondary processing Can cut any straight line, curve, graph, flexible and convenient The slit width is only 1-1.5mm, the cutting surface is smooth without burr, and the roughness is up to 3.2μm-1.6μm Workpiece without special clamping, easy to operate; Wide cutting range, metal cutting thickness up to 150mm.

MECHANICAL ARM WATER JETTING MACHINE

The rack can travel up to four meters, with CAM and other components driving the movement of other parts. It boasts a repeatable positioning accuracy of 0.2mm. The arm, measuring 565mm in length with a 75mm offset, can handle a maximum mass of 2kg.

Additionally, the grab mechanism can reach a maximum speed of 8200mm/s.

Additionally, the grab mechanism can reach a maximum speed of 8200mm/s.

WATER JET CUTTING MACHINE

Our CNC waterjet cutting machine offers no thermal deformation, preserving material integrity and avoiding physical and chemical changes. It is versatile, earning the reputation of a “universal cutting machine” for its suitability with various materials. The machine produces smooth, burr-free cuts that generally require no further processing, and its high precision is controlled by a numerical control system. With a narrow cutting seam of less than 1.2mm, it is efficient for nesting and saving materials. The process is environmentally friendly, producing no waste, and it is ideal for cutting difficult materials like aramid fiber, titanium alloy, and various composites.

Machine Details

Product Parameter

|

Maximum cutting range(mm)

|

3000x2000

|

2500x1500

|

2000x1500

|

1500x1500

|

1500x1000

|

800*800

|

|||||

|

The turret trip(mm)

|

0-200

|

|

|

|

|

|

|||||

|

Driveing speed /servo motor(mm/min)

|

0-10000

|

|

|

|

|

|

|||||

|

Cutting precision(mm)

|

0.2

|

|

|

|

|

|

|||||

|

Control precision(mm)

|

0.05

|

|

|

|

|

|

|||||

|

Air compressor pressure(mpa)

|

0.6-0.8

|

|

|

|

|

|

|||||

|

Grit size

|

600-100

|

|

|

|

|

|

|||||

|

Software

|

CNC

|

|

|

|

|

|

|||||

Our Factory

Application Field

Hot Searches