⭐

1. The moisture content of the unprocessed grains should be 13.5~5%;

⭐

2. Start the blower and then start the grinder. When the blower and the grinder

are both started, the work bin can be blanking.When the grinding head stock

bin has material, then we operate by the order of the combined grinding brake.

When we shut down the machine, we should shut down the grinder first, then

the blower. Flour milling process should be repeated;

- Product Details

- {{item.text}}

Quick Details

-

Power:

-

13.2 kW, 13.2 kW

-

Weight:

-

850 KG, 850 kg

-

Dimension(L*W*H):

-

2500*1500*3200 mm

-

Product name:

-

Corn Mill Production Line

-

Roller length:

-

350*220 mm

-

Capacity:

-

200 kg/h

-

Fast roller speed:

-

650 r/min

-

Machine size:

-

2500*1500*3200 mm

-

Operation:

-

Automtic

-

Used for:

-

Factory

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Xing

-

Voltage:

-

380 V, 380 V/50 Hz

-

Power:

-

13.2 kW, 13.2 kW

-

Weight:

-

850 KG, 850 kg

-

Dimension(L*W*H):

-

2500*1500*3200 mm

-

Product name:

-

Corn Mill Production Line

-

Roller length:

-

350*220 mm

-

Capacity:

-

200 kg/h

-

Fast roller speed:

-

650 r/min

-

Machine size:

-

2500*1500*3200 mm

-

Operation:

-

Automtic

-

Used for:

-

Factory

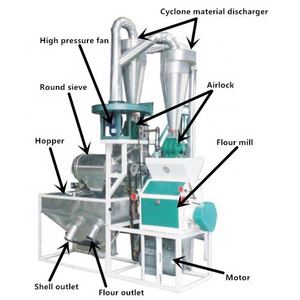

Product Overview

Corn Mill Production Line

This machine is mainly used in small size of coarse grain flour milling plants. It has the features of complete function, low noise, no dust, high degree of automation, convenient installation and low production cost. It grinds wheat into flour by the grinding roll of the grinder. Then the flour is winnowed and screened by the circular screen. At last, we package the flour and the bran separately.

FEATURES AT A GLANCE

⭐3. We can adjust the roll clearance

three

to

four

times successively until

it reaches

the flour

yield.

It can

adjust

the flow by adjusting

the

clearance

between

the flow plate and the

feeding

roll. Rotating

the hand wheel screw can

adjust

the

flow;

⭐ 4. High automation degree, reasonable structure, stable running, reliable features, low energy consumption, high efficiency, low production cost, good benefit, low noise, no dust, safety and sanitation, energy conservation and environmental protection,easyinstallation and convenient maintenance.

SIMILAR PRODUCTS

Details Images

Finished product

Packing and shipping:

Company information:

Our services:

1) Highly inspecting equipments in every working procedure, quality comes first; Fast & Safe Delivery;

2) Assisting our clients for foundation construction of equipment;

3) Dispatching engineers to install and debug equipment;

4) Training the first-line operators on site;

5) Regularly visit clients to solve production problems;

6) Providing life-long maintenance service;

7)Providing technical exchanging;

2) Assisting our clients for foundation construction of equipment;

3) Dispatching engineers to install and debug equipment;

4) Training the first-line operators on site;

5) Regularly visit clients to solve production problems;

6) Providing life-long maintenance service;

7)Providing technical exchanging;

FAQ:

10 ton per day wheat flour milling machine with low price

10 ton per day wheat flour milling machine with low price

10 ton per day wheat flour milling machine with low price

Hot Searches