- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

DM-6715

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

DeepMaterial

-

Model Number:

-

DM-6715

-

Type:

-

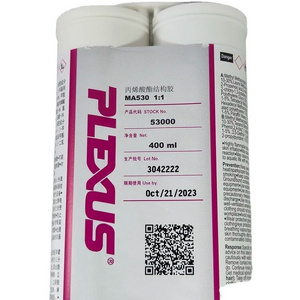

Best Double-Component Acrylic Adhesive

-

Product name:

-

Best Double-Component Acrylic Adhesive

-

Material:

-

One-component potting materials

-

Storage temperature:

-

-20-8℃

-

Curing method:

-

Heat curing

-

Use:

-

most metals, ceramics, rubber, plastics, wood

-

Color:

-

Lilac colloid

-

Product Description:

-

two-component low-odor acrylic structural adhesive

-

Curing system:

-

.At room temperature (23°C)

-

Feature:

-

high shear, high peeling, and good impact resistance

-

Glue type:

-

Epoxy resin-based

Quick Details

-

CAS No.:

-

DM-6715

-

Other Names:

-

Best Double-Component Acrylic Adhesive

-

MF:

-

NONE

-

EINECS No.:

-

DM-6715

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

DeepMaterial

-

Model Number:

-

DM-6715

-

Type:

-

Best Double-Component Acrylic Adhesive

-

Product name:

-

Best Double-Component Acrylic Adhesive

-

Material:

-

One-component potting materials

-

Storage temperature:

-

-20-8℃

-

Curing method:

-

Heat curing

-

Use:

-

most metals, ceramics, rubber, plastics, wood

-

Color:

-

Lilac colloid

-

Product Description:

-

two-component low-odor acrylic structural adhesive

-

Curing system:

-

.At room temperature (23°C)

-

Feature:

-

high shear, high peeling, and good impact resistance

-

Glue type:

-

Epoxy resin-based

PRODUCT DESCRIPTION

PRODUCT FEATURE

-

Fast cure

-

One component

-

Cures in shadowed areas

-

Easy dispensability without stringing

-

Fluorescent under UV light

APPLICATION

-

For assembly process of electron product, especially protection of WLCSP and BGA oncircuit board

-

Suitable for glass, metal, PC substrate adhesion in industrial applications, typicalapplication is mainly used for electronic components of moisture-proof protection.

PHYSICAL PROPERTIES

|

Chemical composition

|

polymer |

| Number of components | single-component |

| Technical characteristics | fast curing, UV-polymerized |

| Applications |

It is a two-component low-odor acrylic structural adhesive, which produces less odor than traditional acrylic adhesives when applied. At

room temperature (23°C), the operating time is 5-8 minutes, the curing position is 15 minutes, and it is usable in 1 hour. After being fully

cured, it has the characteristics of high shear, high peeling, and good impact resistance. Suitable for bonding most metals, ceramics,

rubber, plastics, wood.

|

| Working temperature |

100 °C, 120 °C (212 °F) |

1. What’s the minimum order quantity(MOQ)?

- Minimum 1 unit, small batch and large volumes are acceptable.

2. When can I get the quotation?

- We usually respond within 24 hours on working days receiving your messages.

After we receive the TDS report or sample, we will forward to you with quotation within one week.

3. Which is the safe payment method to trade?

- We accept T/T, LC, Paypal, Trade Assurance and Secure payment on Alibaba platform.

4. How long does it take to deliver?

- For standard adhesive, it will be 7 days for manufacturing.

- For non-standard adhesive, it will be negotiated customized according to your requirements.

5. What’s the shipping method?

- We are able to ship worldwide where Ocean shipping or Air shipping can reach.

- We have a professional packaging team. Products will be packed safely and protectively.

Our Factory specializing in adhesives for semiconductor and electronic applications and surface protection materials for chip packaging and testing. Based on the core technology of adhesives, DeepMaterial has developed adhesives for chip packaging and testing, circuit board-level adhesives, and adhesives for electronic products. Based on adhesives, it has developed protective films, semiconductor fillers, and packaging materials for semiconductor wafer processing and chip packaging and testing. To provide electronic adhesives and thin-film electronic application materials products and solutions for communication terminal companies, consumer electronics companies, semiconductor packaging and testing companies, and communication equipment manufacturers,to solve the above-mentioned customers in process protection, product high-precision bonding, and electrical performance. Domestic substitution demand for protection, optical protection, etc.