Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

OICNC31-230829

-

Brand Name:

-

OI

-

Product Name:

-

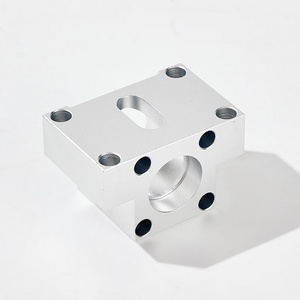

Custom CNC Machined Parts CNC Machining Services

-

Material:

-

Aluminum, Stainless Steel, Brass, Copper, Titanium

-

CNC Processes:

-

CNC Milling, CNC Turning, CNC Turning and Milling Hybrid Machine

-

Service:

-

OEM/ODM CNC Machining Service

-

Usage:

-

Auto Parts, Mechanical Assembly Parts, Spare Parts Components

-

Surface Treatment:

-

Anodizing, Polishing, Electroplating, Powder Coating, Sandblasting

-

Packing:

-

Bubble Bag + Standard Carton

-

Drawing Format:

-

DWG, DXF, PDF, SOLIDWORKS, PRT, STP, STEP, IGS, etc.

-

Certification:

-

ISO 9001:2015

-

MOQ:

-

1 Pcs

Quick Details

-

CNC Machining or Not:

-

Cnc Machining

-

Material Capabilities:

-

Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless steel, Steel Alloys, Titanium

-

Place of Origin:

-

Zhejiang, China

-

Model Number:

-

OICNC31-230829

-

Brand Name:

-

OI

-

Product Name:

-

Custom CNC Machined Parts CNC Machining Services

-

Material:

-

Aluminum, Stainless Steel, Brass, Copper, Titanium

-

CNC Processes:

-

CNC Milling, CNC Turning, CNC Turning and Milling Hybrid Machine

-

Service:

-

OEM/ODM CNC Machining Service

-

Usage:

-

Auto Parts, Mechanical Assembly Parts, Spare Parts Components

-

Surface Treatment:

-

Anodizing, Polishing, Electroplating, Powder Coating, Sandblasting

-

Packing:

-

Bubble Bag + Standard Carton

-

Drawing Format:

-

DWG, DXF, PDF, SOLIDWORKS, PRT, STP, STEP, IGS, etc.

-

Certification:

-

ISO 9001:2015

-

MOQ:

-

1 Pcs

Product Specification

|

Accurate CNC Machining, Prompt Response, Efficient Production

|

|

|

|

Product Name

|

Custom CNC Machined Parts CNC Machining Services

|

|

|

Quotation

|

Contact Us to Get a Quotation Within 24 Hours

|

|

|

Our Lead Times

|

Sample:5 Days, Mass Production:2 Weeks

|

|

|

Materials

|

Metal:

Aluminum, Stainless Steel, Copper, Iron, Titanium Alloy, Zinc Alloy, Magnesium Alloy.

Plastic:

Nylon, ABS, POM, PC, PP, PE, PETG, PEEK, PMMA, PVC, UHMW.

|

|

|

Surface Treatment

|

Anodizing, Polishing, Electroplating, Powder Coating, Sandblasting, Magnetic Polishing, Spray Painting, Drawing, Embossing, Electrophoresis, Screen Printing, Laser Engraving.

|

|

|

CNC Processes

|

3-Axis/4-Axis/5-Axis/6-Axis CNC Milling, CNC Turning, CNC Turning and Milling Hybrid Machine.

|

|

|

Maximal Part Size

|

3000 mm (118 in)

|

|

|

Minimal Part Size

|

2 mm (0.08 in)

|

|

|

Drawing Formats

|

DWG, DXF, PDF, SOLIDWORKS, PRT, STP, STEP, IGS, etc.

|

|

|

Certificated

|

ISO 9001:2015

|

|

Products Description

We Have 300+ CNC Lathes for Your Customized Needs

at Various Precision Levels.

CNC Turning

A Machining Process That Rotates a Workpiece While a Cutting Tool Removes Material from the Surface, Suitable for Cylindrical or Round-Shaped Parts Made of Various Materials Such as Metals, and Plastics, And Woods.

Advantages:

High Precision, Repeatability, And Efficiency in Mass Production.

CNC Milling

A Machining Process That Uses Rotary Cutters to Remove Material from a Workpiece, Suitable for Flat or Irregularly Shaped Parts Made of Various Materials Such as Metals, Plastics, And Woods.

Advantages:

Versatility in Creating Complex Shapes, High Precision, Repeatability, And Efficiency in Mass Production.

|

CNC Orientation and Form General Tolerances

|

|

|

||

|

Part Length

|

Orientation and Form Tolerance

|

Angularity Tolerance

|

||

|

0 to 12"(300 mm)

|

±0.005"(0.125 mm)

|

Angularity ±0.5 degree

|

||

|

12"to 24"(600 mm)

|

±0.010"(0.250 mm)

|

Angularity ±0.5 degree

|

||

|

24"to 36"(900 mm)

|

±0.016"(0.400 mm)

|

Angularity ±1 degree

|

||

|

36"to 60"(1500 mm)

|

±0.031"(0.790 mm)

|

Angularity ±1 degree

|

||

|

Over 60"

|

±0.063"(1.600 mm)

|

Angularity ±1 degree

|

||

Available Finishes

Anodizing

Electrochemical Treatment That Forms an Oxide Layer to Enhance Hardness, Corrosion Resistance, And Glossiness, Suitable for Aluminum, Titanium.

Advantages:

Improved Hardness and Corrosion Resistance, Enhanced Appearance.

Polishing

Mechanical Treatment That Uses Abrasives or Polishing Agents to Achieve a Smooth and Shiny Surface, Suitable for Various Metals and Plastics.

Advantages:

Improved Brightness and Smoothness, Enhanced Appearance.

Sandblasting

Mechanical Treatment That Uses High-Pressure Sandblasting to Remove Dirt, Oxide Layers, Scratches, And Rust, Suitable for Various Metals and Plastics.

Advantages:

Improved Cleanliness and Roughness, Enhanced Appearance.

Electroplating

Electrochemical Treatment That Deposits a Metal Coating to Improve Surface Hardness, Suitable for Various Metals and Plastics.

Advantages:

Improved Hardness, Corrosion Resistance, Enhanced Appearance.

Spray Painting

Mechanical Treatment That Sprays Paint or Coating to Enhance Surface Functionality and Appearance, Suitable for Various Metals and Plastics.

Advantages:

Improved Color, Protection, And Wear Resistance, Enhanced Appearance.

Powder Coat

Sprays Electrostatically Charged Powder, Then Heats It to Create a Durable and Uniform Coating. Suitable for Aluminum, Stee, Magnesium.

Advantages:

Excellent Durability, Scratching, And Fading, As Well as Resistance to Chemicals, Corrosion.

Customer Reviews & Product Showcases

About Us

FAQ

Q1: How Can I Get a Quote?

Q6: What Should I Do if I Encounter Any Problems After Receiving the Product?

A1:

If You Are a Professional,

You Can Get a Quote by Sending Drawings and Requirements or Instructions. We Will Reply to You as Soon as Possible and Provide You with a Quote.

If You Are Not a Professional, You Can Tell Us Your Specific Needs. Our Professional Team Will Provide You with Multiple Customized Solutions Based on Your Needs and Provide You with a Quote.

If You Are Not a Professional, You Can Tell Us Your Specific Needs. Our Professional Team Will Provide You with Multiple Customized Solutions Based on Your Needs and Provide You with a Quote.

Q2: Are My Drawings Safe?

A2: Yes. We Can Sign a Confidentiality Agreement and Take Strict Measures to Protect Your Data.

Q3: What Is the Delivery Time?

A3: The Delivery Time Will Depend on the Order Quantity. We Usually Complete the Delivery Within 3-15 Days After Order Confirmation.

Q4: Can I Get a Sample to Check?

A4: Yes, You Can. You Only Need to Pay the Cost of the Sample, And We Will Refund It to You During Mass Production.

Q5: How Can I Customize a Part if I Can't Draw?

A5: No Problem. Tell Us Your Requirements and We Provide Design Services.

A6: You Can Provide Feedback to Our After-Sales Service Team Through Voice Calls, Video Conferences, Emails, And Other Methods. Our Team Will Reply to You Within 24 Hours and Provide You with the Best Solution Within a Week.

Hot Searches