By sea, by air, by express.

On-time delivery as well as a long-term warranty and after-sale service.

A strong ability to warehousing logistics and a strong factory as a backstop.

- Product Details

- {{item.text}}

Quick Details

-

MF:

-

ZrO2

-

EINECS No.:

-

215-227-2

-

Place of Origin:

-

Guangdong, China

-

Appearance:

-

White Powder

-

Application:

-

For making ceramics, refractory material,etc

-

Brand Name:

-

Shenghua

-

Model Number:

-

ZrO2

-

Product name:

-

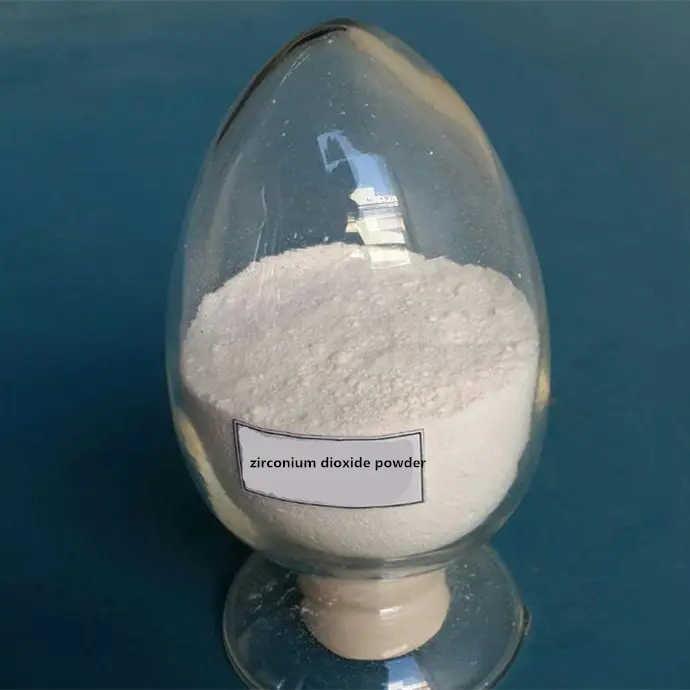

ZrO2 zirconium oxide powder

-

MOQ:

-

100 gram

-

Grade:

-

Industrail Grade

-

Package:

-

standard or customer's request

-

Sample:

-

Availiable

-

Feature:

-

small particle diameter, narrow distribution range, activity stable

-

Color:

-

White Color

-

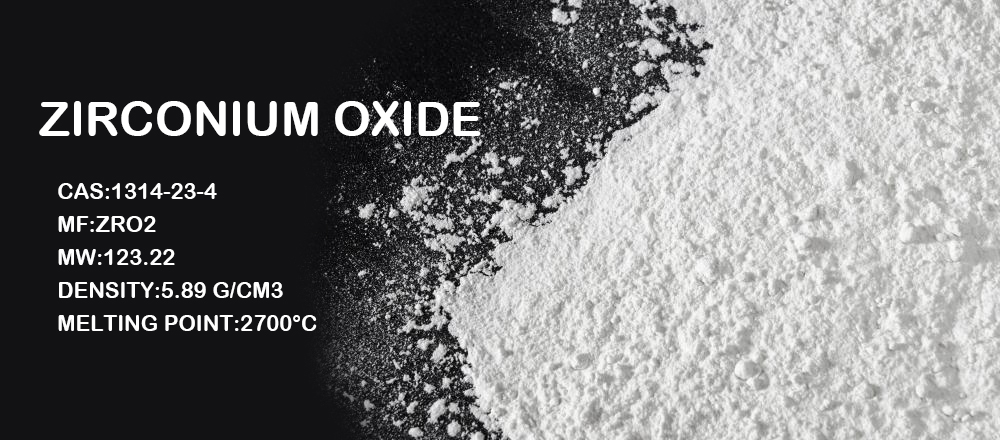

CAS:

-

1314-23-4

-

Keywords:

-

Zirconium Oxide Ceramic Powder

-

Shape:

-

Powder Material

Quick Details

-

CAS No.:

-

1314-23-4

-

Purity:

-

99%

-

Other Names:

-

ZrO2 zirconium oxide

-

MF:

-

ZrO2

-

EINECS No.:

-

215-227-2

-

Place of Origin:

-

Guangdong, China

-

Appearance:

-

White Powder

-

Application:

-

For making ceramics, refractory material,etc

-

Brand Name:

-

Shenghua

-

Model Number:

-

ZrO2

-

Product name:

-

ZrO2 zirconium oxide powder

-

MOQ:

-

100 gram

-

Grade:

-

Industrail Grade

-

Package:

-

standard or customer's request

-

Sample:

-

Availiable

-

Feature:

-

small particle diameter, narrow distribution range, activity stable

-

Color:

-

White Color

-

CAS:

-

1314-23-4

-

Keywords:

-

Zirconium Oxide Ceramic Powder

-

Shape:

-

Powder Material

Products Description

Factory Grinding Ball 0.1mm-50mm Yttria Stabilized ZrO2 Zirconium Oxide/Zirconia Ceramic Beads/Balls

The content of zirconia in the beads is approximately 95% so it is usually called "95 Zirconium" or "Pure zirconia beads". With the rare earth yttrium oxide as stabilizer and the raw material of high whiteness and fineness, there will be no pollution to the grinding material.It is mainly used in the ultra-fine grinding and dispersion of materials requiring "zero pollution" and high viscosity and high hardness, such as: electronic ceramics, magnetic materials, zirconia, silicon oxide, zirconium silicate, titanium dioxide, medicine and food, pigments, dyes, ink, special chemical industry.

How to choose the grinding medium ?

The size selection of the grinding medium depends on the initial and final particle size of the grinding material.

01.Broken or easily broken materials: a slightly smaller diameter grinding medium can be selected.

02.Hard to break materials: with slightly larger diameter materials processing, more efficient.

03.The grinding ball size should be larger than the equipment separator or filter.

04.The distance between the dispersion plate and the grinding container wall should be more than 5 times the size of the grinding medium.

02.Hard to break materials: with slightly larger diameter materials processing, more efficient.

03.The grinding ball size should be larger than the equipment separator or filter.

04.The distance between the dispersion plate and the grinding container wall should be more than 5 times the size of the grinding medium.

Common specifications of zirconia beads:

|

φ0.12-0.18mm

|

φ0.18-0.23mm

|

φ0.22-0.28mm

|

φ0.28-0.35mm

|

φ0.35-0.45mm

|

|

|

φ0.4-0.6mm

|

φ0.6-0.8mm

|

φ0.8-1.0mm

|

φ1.0-1.2mm

|

φ1.2-1.4mm

|

|

|

φ1.4-1.6mm

|

φ1.6-1.8mm

|

φ1.8-2.0mm

|

φ2.0-2.2mm

|

φ2.2-2.4mm

|

|

|

φ2.4-2.6mm

|

φ2.6-2.8mm

|

φ2.8-3.0mm

|

φ3.0-3.2mm

|

φ3.2-3.4mm

|

|

|

φ3.8-4.0mm

|

φ4.0-4.3mm

|

φ4.3-4.8mm

|

φ4.8-5.3mm

|

φ4.8-6.3mm

|

|

|

φ5mm

|

φ6mm

|

φ7mm

|

φ8mm

|

φ10mm

|

|

|

φ12mm

|

φ15mm

|

φ17mm

|

φ20mm

|

φ25mm

|

|

|

φ30mm

|

φ40mm

|

φ50mm

|

Note: Other sizes can be customized

|

|

|

Featrue&Advantage:

* Uniform size

* Thermostability

* High hardness, and strength * Highly resistant to abrasion and corrosion

* Low cost * Excellent durability

* wear-resistance * Long service time

Application Scenarios

1. Bio-tech (DNA, RNA & protein extraction and isolation)

2. Chemicals including Agrochemicals e.g. fungicides, insecticides and herbicides

3. Coating, paints, printing and inkjet inks

4. Cosmetics (Lipsticks , Skin & sun protection creams)

5. Electronic materials and components e.g. CMP slurry, ceramic capacitors, lithium iron phosphate battery

6. Minerals e.g. TiO2, Calcium Carbonate and Zircon

7. Pharmaceuticals

8. Pigments and dyes

9. Flow distribution in process technology

10. Vibro-grinding and polishing of jewelrys, gemstones & aluminum wheels

11. Sintering bed with good thermal conductivity, can sustain high temperatures

2. Chemicals including Agrochemicals e.g. fungicides, insecticides and herbicides

3. Coating, paints, printing and inkjet inks

4. Cosmetics (Lipsticks , Skin & sun protection creams)

5. Electronic materials and components e.g. CMP slurry, ceramic capacitors, lithium iron phosphate battery

6. Minerals e.g. TiO2, Calcium Carbonate and Zircon

7. Pharmaceuticals

8. Pigments and dyes

9. Flow distribution in process technology

10. Vibro-grinding and polishing of jewelrys, gemstones & aluminum wheels

11. Sintering bed with good thermal conductivity, can sustain high temperatures

Customer Reviews

Every feedback from clients will be the motivation for us to continuously improve and develop!

Certifications and Exhibition

Packing and Shipping

Packing details:

Packing:

25kgs/Bag

Production capacity: 200000+

bags

/month

Promote shipping usually 7--14 days after receiving T/T deposit or L/C Original.

Shipping details:

Hot Searches