- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

GREATCITY

-

Voltage:

-

380v50hz3 phase

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

2500 kg

-

Feeding width:

-

1000mm ,1200mm or customized

-

Name:

-

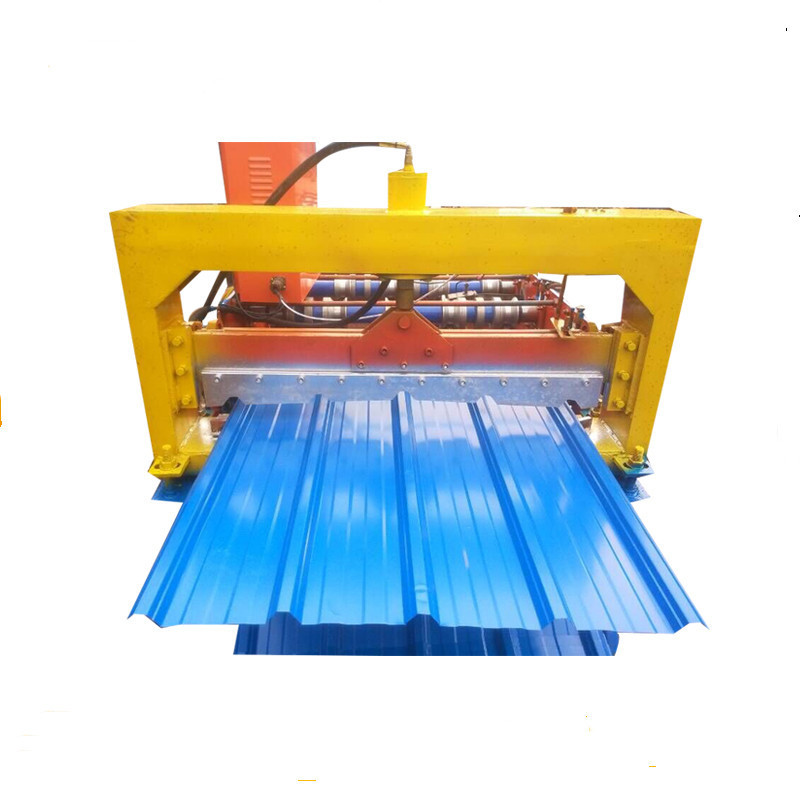

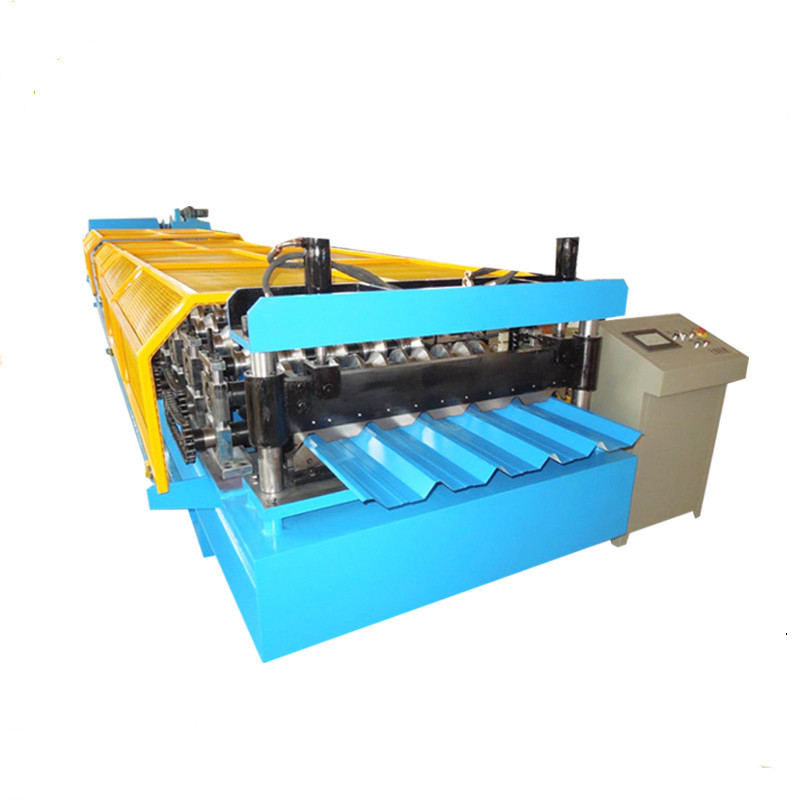

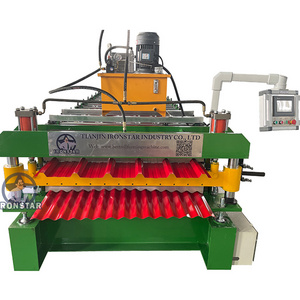

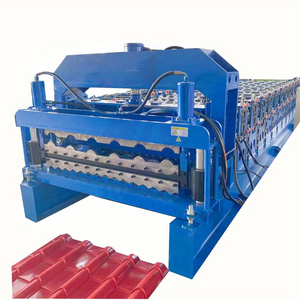

Double layer roof Roll forming machine

-

color:

-

blue/red/yellow/and so on

-

raw materials:

-

colord steel sheet or Galvanized steel sheet

-

voltage:

-

380v 50HZ 3PHASES or customized

-

Power:

-

4+3kw

-

work efficiency:

-

8-12m/miniute

-

usage:

-

roof, wall,floor

-

processed layer:

-

double

-

Cutting blade material:

-

Cr12 Quenched

-

Shaft material:

-

High Grade No.45 Forged

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Colored Steel

-

Production Capacity:

-

8-12m/minute

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

GREATCITY

-

Voltage:

-

380v50hz3 phase

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

2500 kg

-

Feeding width:

-

1000mm ,1200mm or customized

-

Name:

-

Double layer roof Roll forming machine

-

color:

-

blue/red/yellow/and so on

-

raw materials:

-

colord steel sheet or Galvanized steel sheet

-

voltage:

-

380v 50HZ 3PHASES or customized

-

Power:

-

4+3kw

-

work efficiency:

-

8-12m/miniute

-

usage:

-

roof, wall,floor

-

processed layer:

-

double

-

Cutting blade material:

-

Cr12 Quenched

-

Shaft material:

-

High Grade No.45 Forged

High speed Double layer roof sheet roll forming machine manufacturer

Specification of roof sheet roll forming machine

All the technical parameters are also made as per the cutomers' requirements.

| 1.Weight capacity of decoiler | 4T |

| 2.Appearance Size(L*W*H) | 6500*1500*1500 |

| 3.Raw material /feeding sheet material | Colored steel & galvanized steel |

| 4.Roller material | 45# high grade steel |

| 5.Shaft material | 45# high grade steel |

| 6.Kind of drive | Chain drive |

| 7.Cutting system | Automatic hydyaulic cutting |

| 8.Cutting blade material | Cr 12 high grade steel |

| 9.Frame material | 300 H-high grade steel |

| 10.Control system | Totally automatic PLC control system |

| 11.Main power | 4kw |

| 12.Roller stations | 13 rows |

| 13.Speed of production | 8-12m/min |

| 14.Thickness of colored steel | 0.3-0.8mm |

| 15.Feeding width | 1000mm |

| 16.Effectiv width | 840/900mm |

| 15.Frame material | 300 H-steel |

roof sheet roll forming machine detailed show :

roof sheet roll forming machine

workflow

:

Decoiler→Flating→Feeding →Forming→Cut to length→Collection(finish goods)

Packing :export wooden case or Nude, with waterproof cloth and stow-wood.PLC industrial computer control system packed with waterproof cloth and card board for

roof sheet roll forming machine

Delivery time: about 15-20 days after receipt of the deposit.