- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

none

-

Year:

-

2024

-

Power (kW):

-

80 kW

-

Weight (KG):

-

9000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

markets:

-

20 more countries

-

Reclaimed Rubber Production Machinery:

-

2014 High Quality Reclaimed Rubber Production Machinery

-

type:

-

Rubber Devulcanizer Machine

-

machine type:

-

Rubber Devulcanizer Machine

-

color:

-

as your require

-

main market:

-

all over the world

-

Weight:

-

none

-

Power(W):

-

90-110 kw

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

eenor

-

Voltage:

-

220-510 V

-

Dimension(L*W*H):

-

none

-

Year:

-

2024

-

Power (kW):

-

80 kW

-

Weight (KG):

-

9000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

markets:

-

20 more countries

-

Reclaimed Rubber Production Machinery:

-

2014 High Quality Reclaimed Rubber Production Machinery

-

type:

-

Rubber Devulcanizer Machine

-

machine type:

-

Rubber Devulcanizer Machine

-

color:

-

as your require

-

main market:

-

all over the world

-

Weight:

-

none

-

Power(W):

-

90-110 kw

High Quality Reclaimed Rubber Machine / Rubber Devulcanizer Machine

1. Boiler Burning coal

| model | YG-L350 |

| rated output: M cal/h | 30 |

| effciency | ≥65 |

| design pressure (Mpa) | 0.6 |

| maximum temp | 280 |

| circulating flow (m3/h) | 30 |

| capacity (m3) | 0.28 |

| pipe diameter (mm) | 80 |

| electricity consumption (kw) | 18 |

| consumption (kg/h) | 90(coal) |

| weight (kg) | 3500 |

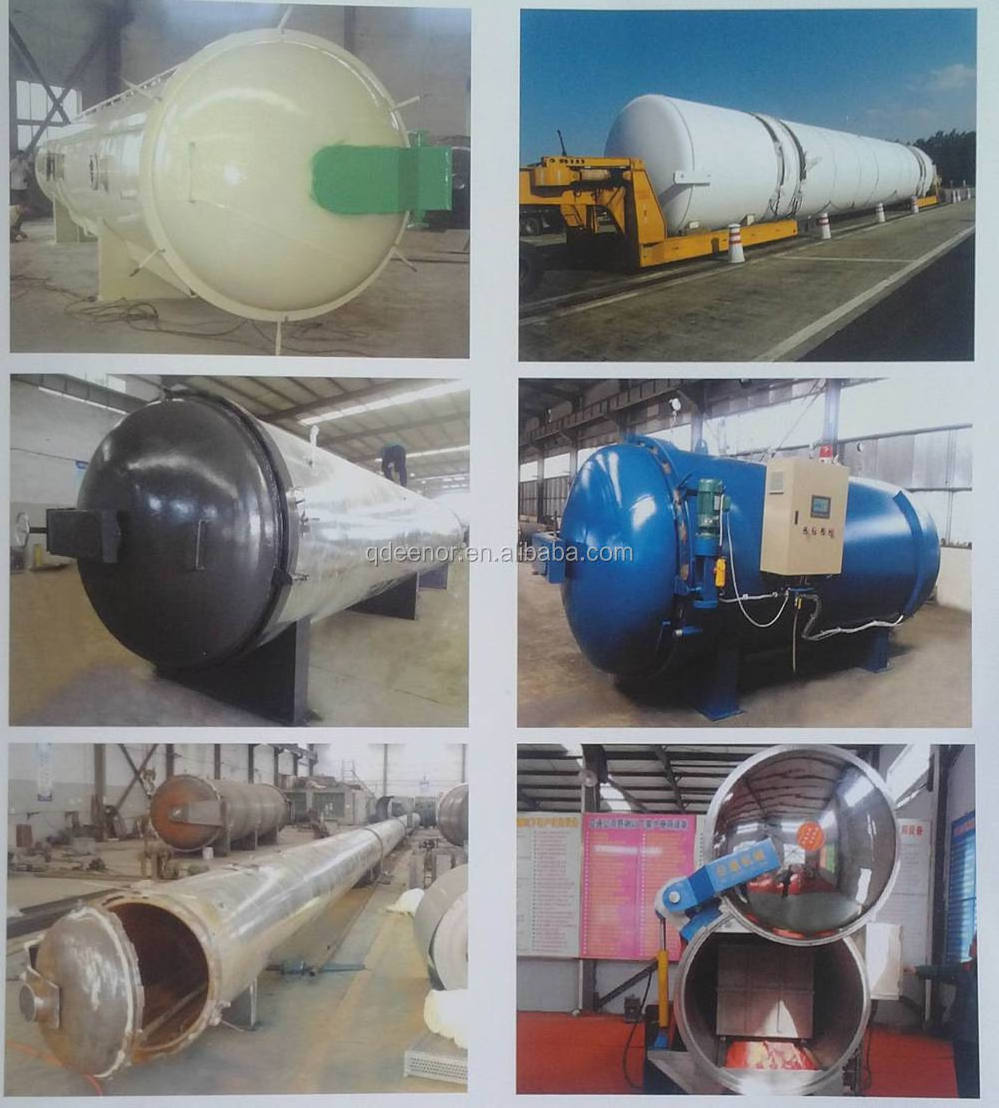

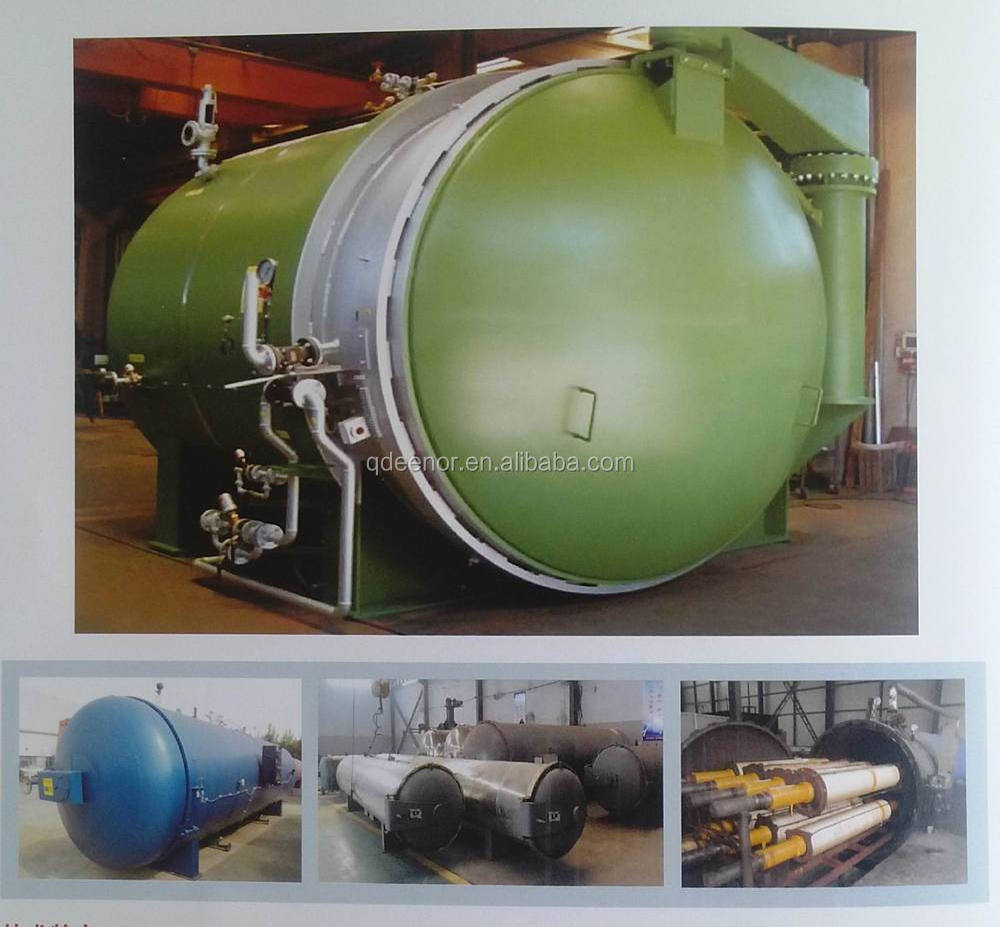

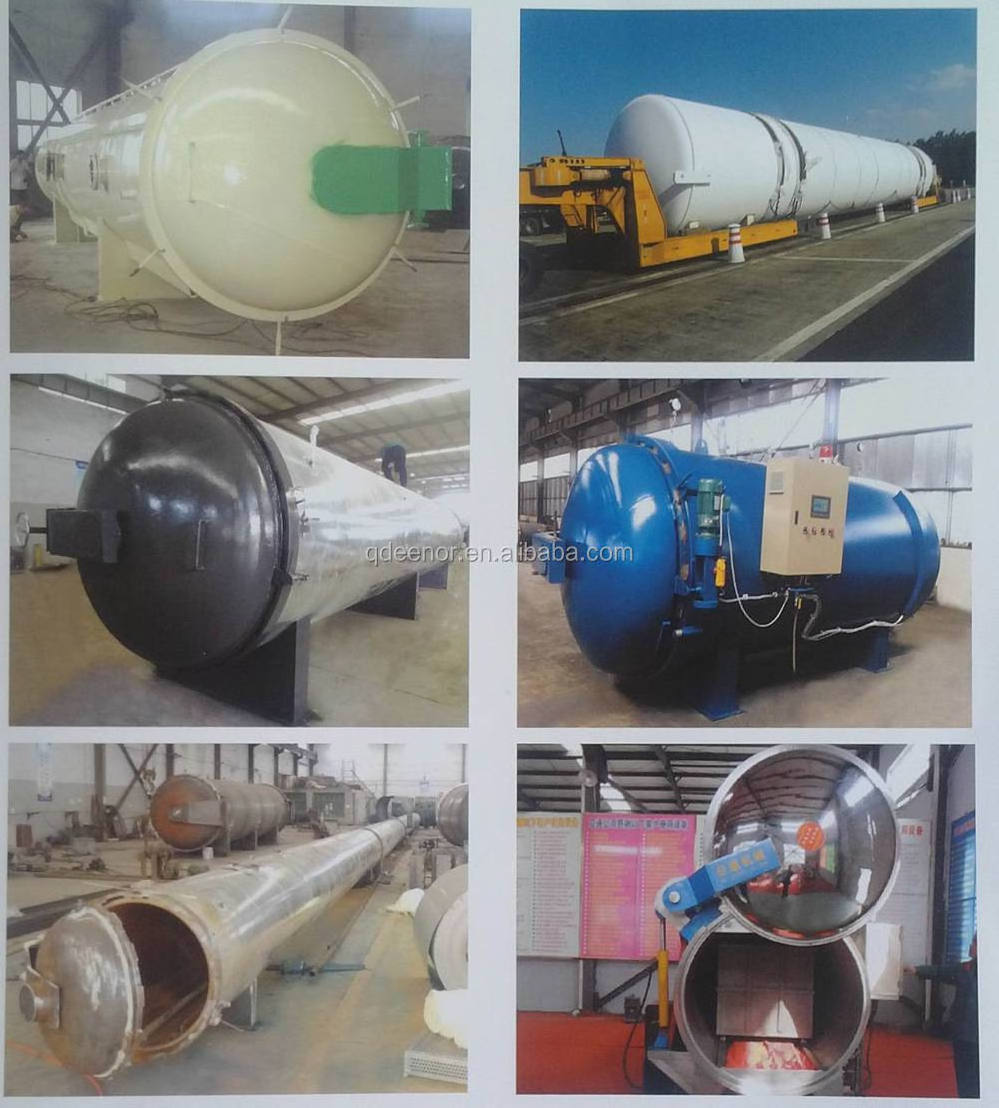

2. Dynamic desulfurization tank

| Model | DTG-Φ1400x1800A |

| Interior diameter of container (mm) | 1400 |

| Working length of container (mm) | 1800 |

| working pressure of container | 2.8 |

| Working temperature | 230 |

| Heating medium | steam |

| Major pressurized material | 16 mnr |

| Container classification | mr-2 |

| Rotaing speed of mixing shaft (r/min) | 16 |

| Heating method | oil heating |

| Main motor power (kw) | 15 |

| Feeding and discharging method | automatic |

| Total cubage (M3) | 3 |

| Overall dimensions (L*W*H) mm | 3800*2000*2060 |

| Weight (kgs) | 6500 |

3- Preliminary refining:

| Type | Xk-160 | Xk-250 | Xk-300 | Xk-400 | Xk-450 | Xk-560 | Xk-660 |

| Working diameter of rolls (mm) | 160 | 250 | 300 | 400 | 450 | 560 | 660 |

| Working length of rolls (mm) | 320 | 620 | 750 | 1000 | 1200 | 1530 | 2130 |

| Front roll surface speed (m/min) | 8.95 | 14.1 | 15.1 | 18.65 | 24.26 | 27.72 | 28.6 |

| Friction ratio | 1:1.35 | 1:1.17 | 1:1.27 | 1:1.27 | 1:1.27 | 1:1.2 | 1:1.24 |

| Max.nip (mm) | 4.5 | 8 | 8 | 10 | 15 | 15 | 15 |

| Capacity per.batch (kg) | 1-2 | 8-15 | 15-20 | 18-35 | 25-50 | 35-50 | 165 |

| Motor power (kw) | 5.5 | 18.5 | 22 | 37 | 55 | 90 | 245 |

4- RUBBER STRAINER:

| Type | XJL-150 rubber strainer |

| Screw diameter (mm) | 150 |

| Screw ratio (r/min) | 53 |

| Screw form | double-head equal-depth and isometry |

| Length-diameter ratio of screw (L/D) | 1:5.14 |

| Motor power (kw) | 37 |

| Production capacity (kg/h) | 300-350 |

| Steam pressure (Mpa) | 0.6-0.8 |

| Cooling water pressure | 0.2-0.4 |

5. RUBBER REFINER

| Type | XKJ-400 | XKJ-450 | XKJ-480 |

| Front roll diameter (mm) | 400 (waist-drum) | 450 (waist-drum) | 480 (waist-drum) |

| Rear roll diameter (mm) | 510 (waist-drum) | 510 (wasit-drum) | 612 (wasit-drum) |

| working length of rolls (mm) | 760 | 800/1000 | 800 |

| Front roll surface speed (m/min) | 24.98 | 48/32 | 22.97 |

| Friction ratio | 1:1.707 | 1:1.82 | |

| Max.nip | 10 | 10 | 15 |

| Production capacity (kg/h) | 400 | 475 | 500 |

| Motor power (kw) | 45 | 55 | 75 |

packing:

company:

FAQ:

1.Q:Are you a factory or trading company?

A:We are factory.

2.Q:Where is your factory?How can i visit ?

A:Our factory located in qingdao city.You can fly to qingdao liuting airport,then we can pick you up to our facotry to visit.Warm welcome visit us.

3.Q:How does your factory control the quality of machines and after sales service?

A:Our machines passed CE,BV,ISO,SGS certification,pls confirm the quality.All our machines have 1 year guarantee, will provide lifetime maintenance.

Why choose us?

We are ready to give them a turnkey solution, by designing the line according to their space, designing all electrical Installation, water installation, civil foundation, training their people and proving that they will get the targets for production according to the design.

The cost of the machinery they are paying is one off but the correct production design and machine configuration in order to get the production targets is the most important point. Even if somebody got the cheapest machine quotation, at the end of the day, what is count are the production quantity, quality and the durability of the machines so to cover the investment in the correct time.

A satisfies customer can bring you ten more customers but one disappointed customer can send away one hundred customers. Reputation in the market is the most important factor for keeping business healthy and in growing line.

Guarantee & After-sale service:

♥One year guarantee for whole machines

♥24 hours technical support by email

♥Calling or door - to -door service.

♥Provide videos for each machine.

How to contact us?

Send your inquiry details in the below.Click"Send"Now.

If you are intrested in our machine or have any doubt, pls contact me freely.