- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Leizhan

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

width:1200--2600mm

-

Weight (KG):

-

120 kg

-

Transmission Angle:

-

0-25

-

Feeding ability:

-

60--600

-

Feeding speed:

-

10-12m/min

-

Conveying materials:

-

Waste paper, pulp board, other materials

-

Max.Limit of Material:

-

1200-2600mm

-

Name:

-

Conveyor chain for kraft paper production line

-

Application:

-

Paper industry

-

kinds:

-

Lift/Right

-

types:

-

BFW1200 BFW1400 BFW1600 BFW1800 BFW2000 BFW2200 BFW2400 BFW2600

Quick Details

-

Power:

-

5.5--55

-

Warranty:

-

1 Year

-

Width or Diameter:

-

Other

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Leizhan

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

width:1200--2600mm

-

Weight (KG):

-

120 kg

-

Transmission Angle:

-

0-25

-

Feeding ability:

-

60--600

-

Feeding speed:

-

10-12m/min

-

Conveying materials:

-

Waste paper, pulp board, other materials

-

Max.Limit of Material:

-

1200-2600mm

-

Name:

-

Conveyor chain for kraft paper production line

-

Application:

-

Paper industry

-

kinds:

-

Lift/Right

-

types:

-

BFW1200 BFW1400 BFW1600 BFW1800 BFW2000 BFW2200 BFW2400 BFW2600

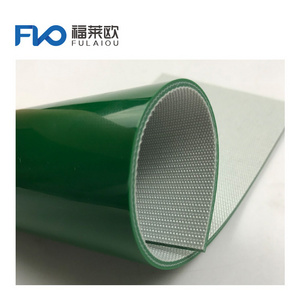

Industrial Conveyor Belt Machine Used for Paper Making Machine Paper Mill

Mainly used for conveying various kinds of bulk or bundled pulp board and waste paper etc.

With reasonable structure, adopt chain plate transmission, drive and conveying material trough plate movement, has large conveying capacity, low power consumption, less wear and tear, the advantages of reliable work, is currently the most ideal paper conveying equipment.

Main specification of BFW series chain conveyor :

|

Type |

BFW Chain Conveyor |

|||||||

|

Chain plate width (mm) |

1200 |

1400 |

1600 |

1800 |

2000 |

2200 |

2400 |

2600 |

|

Feeding c apacity (m 3 /h) |

60-220 |

80-255 |

95-300 |

110-345 |

140-390 |

160-430 |

200-500 |

240-600 |

|

Conveying m aterials |

waste paper/pulp board |

|||||||

|

Max. l imit of m aterial (mm) |

1000 |

1200 |

1400 |

1600 |

1800 |

2000 |

2200 |

2400 |

|

Motor power( k w) |

5.5 |

7.5 |

11 |

15 |

18.5 |

22-30 |

30-45 |

37-55 |

Basic structure of BFW series chain conveyor :

a.Head drive: electromotor, reducer, drive equipment, active sprocket device

b.Tail drive: tail shaft, Sprocket driven

c.Tension device

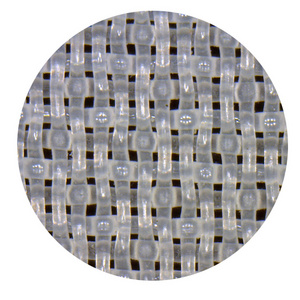

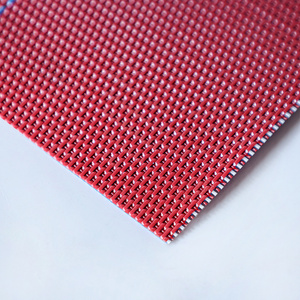

d.Chain plate parts

e.Frames

By our engineer or professional Installation company.

Usage and maintenance of BFW series chain conveyor :

1. Strive to even feeding material when operation, feeding maximum weight should be controlled in the specified scope

2. Stop or start when Stop or start is not suitable

3. Moderation of Traction chain should be reasonable. In the operation should be frequently check and adjust it

4. Reducer must add the lubricating oil after 7-14 days operation, later according to situation, three to six months once.

5. ll lubrication points should be timely injection lubricant

Working site