Zhangjiagang Sky Machine Co.,Itd is located at Leyu Economic Development Zone of Zhangjiagang City.Our Company was founding

in 2008.We committed to do the World’s most competitive liquid drink packaging manufacture suppliers.Focus on providing customers with safe,energy,saving,efficient equipment.And high quality,fast and personalized service. We sincerely invite businesses aroundthe world to build a professional relationship with us based on trust,benefits and the promising possibility for future development.

- Product Details

- {{item.text}}

Quick Details

-

Bottle Volume(ml):

-

500 ml

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

SKY MACHINE

-

Year:

-

2019

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

1800*3200*1900mm

-

Hollow part volume:

-

Adjustable

-

Power (kW):

-

27.5

-

Weight (KG):

-

1750 KG

-

Product name:

-

Bottle Blowing Machine

-

Suitable bottle:

-

Drink Bottle

-

Key words:

-

Blowing Mold Machine

-

Capacity:

-

Customzied

-

PLC:

-

MITISUBISHI

-

Bottle type:

-

Round

-

Production Capacity (BPH):

-

6000 BPH

-

After-sales Service Provided:

-

Provided

Quick Details

-

Neck Diameter(mm):

-

28 mm

-

Max.Bottle Diameter(mm):

-

180 mm

-

Max.Bottle Height(mm):

-

360 mm

-

Bottle Volume(ml):

-

500 ml

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

SKY MACHINE

-

Year:

-

2019

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

1800*3200*1900mm

-

Hollow part volume:

-

Adjustable

-

Power (kW):

-

27.5

-

Weight (KG):

-

1750 KG

-

Product name:

-

Bottle Blowing Machine

-

Suitable bottle:

-

Drink Bottle

-

Key words:

-

Blowing Mold Machine

-

Capacity:

-

Customzied

-

PLC:

-

MITISUBISHI

-

Bottle type:

-

Round

-

Production Capacity (BPH):

-

6000 BPH

-

After-sales Service Provided:

-

Provided

Product Application

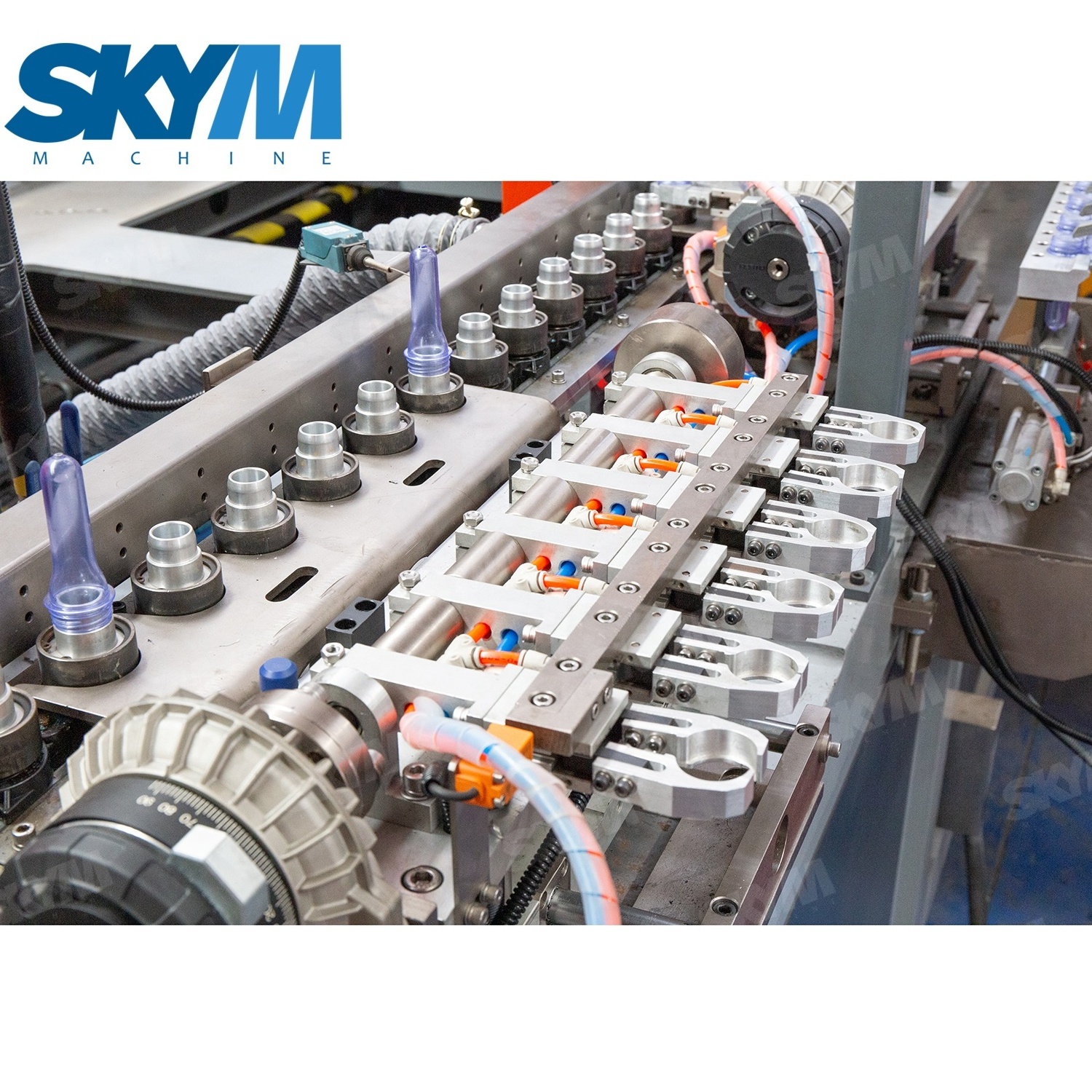

Automatic PET Preform Blowing Molding Machine

This fully-automatic bottle blowing machine is a linear bottle blowing machine which is developed and researched by the most advanced bottom making technology in the current world and molded through blowing PET(Polyethylene Terepthalate)by high pressure compressed gas.The machine needs a bottle blank appropriate to bottle type.this linear bottle blowing machine can be used independently for blowing botles or completion of bottle blowing before filling lines.The machine shows characteristics such as high intelligence,stable and reliable mechanical performance, high production efficiency,low cost and pollution free from intermediate process,it is widely used for production of food,drink,cosmetic vessel.

Automatic PET Bottle Blow Molding Machine Features:

1.Stable and accurate running at high speed,adopt more stable and advanced microcomputer PLC control system.

2. Production process is fully automated, with the advantages of low investment, high efficiency, easy operation, simple

maintenance and safety.

3. Suitable for flexible production of quantity and various bottle shape,wide range of applications,meet customer needs.

4. Manual and automatic methods of operation, human-machine interface control, simple operation.

5. Servo transmission system, high positioning accuracy, fast speed stability and good reliability.

6. Less than 0.2% scrap rate for finished bottle .

2. Production process is fully automated, with the advantages of low investment, high efficiency, easy operation, simple

maintenance and safety.

3. Suitable for flexible production of quantity and various bottle shape,wide range of applications,meet customer needs.

4. Manual and automatic methods of operation, human-machine interface control, simple operation.

5. Servo transmission system, high positioning accuracy, fast speed stability and good reliability.

6. Less than 0.2% scrap rate for finished bottle .

7. With advanced PLC control system, the performance is stable and outstanding.

8. Automatic feeding of conveyor belt.

9. The heat penetration is strong and the preform is rotated by itself, so that the preform receives even heat during the preheating process.

10. High adaptability. By adjusting the distance between the lamp and the reflector, the preform can fully absorb heat. Equipped with an automatic constant temperature device, the temperature can be continuously maintained within a certain range.

10. High adaptability. By adjusting the distance between the lamp and the reflector, the preform can fully absorb heat. Equipped with an automatic constant temperature device, the temperature can be continuously maintained within a certain range.

11. There is a safety locking device during each mechanical action to protect the operator's safety.

12. Use air cylinder instead of hydraulic cylinder, less pollution and low noise.

13. Use different air pressures for bottle blowing and machine operation, the fan is energy-saving and environmentally friendly.

14. Equipped with high pressure and double crank connecting rod clamping to provide high clamping force.

15. With automatic and manual operation modes .

16. Safe, reliable and unique valve position design makes the blowing process easier to control.

17. Low cost, high efficiency, easy operation, easy maintenance, etc., advanced automatic

process.

18. Avoid contamination of the bottle.

19. Protection of cryogenic cooling systems.

20. Easy to install and start.

21. Low scrap rate.

Machine Details

Customized Bottle Design

Real Picture Of Customer Factory

Product Paramenters

|

Model

|

SKY-2000

|

SKY-3000

|

SKY-4000

|

SKY-6000

|

SKY-8000

|

|

Bottle volume range

|

0.05~2Liter

|

0.05~1.5Liter

|

0.05~2Liter

|

0.05~2Liter

|

0.05~2Liter

|

|

Production Speed

|

2000bottles per hour(500ml)

|

3000bottles per hour(500ml)

|

4000bottles per hour(500ml)

|

6000bottles per hour(500ml)

|

8000bottles per hour(500ml)

|

|

Bottle diameter

|

20mm-100mm

|

20mm-100mm

|

20mm-100mm

|

≤90mm

|

≤90mm

|

|

Cavity

|

2cavity

|

3cavity

|

4cavity

|

6cavity

|

8cavity

|

|

Dimension

|

1900*1280*1920cm(L*W*H)

|

1750*1250*2050cm(L*W*H)

|

1900*1850*1920cm(L*W*H)

|

5000*2800*2200cm(L*W*H)

|

5500*4000*2200cm(L*W*H)

|

|

Weight

|

2000kg

|

1600kg

|

3600kg

|

4800kg

|

5800kg

|

ABOUT SKYM

Hot Searches