- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.5-1.5mm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Sussman

-

Voltage:

-

380V 50Hz or customized

-

Dimension(L*W*H):

-

About 5500*800*1200mm

-

Weight:

-

5000 kg

-

Feeding width:

-

60-250mm

-

Marketing Type:

-

cheap price

-

Material thickness:

-

0.5-1.5mm galvanized steel

-

Producting speed:

-

20-30m/min

-

Roller station:

-

About 13 stations

-

Hydraulic station:

-

7.5KW

-

Main Power:

-

11KW

-

Materia of cutting:

-

Cr12Mov

-

Hardness:

-

HRC58-62

-

Way Of Drive:

-

Chain driven

-

Material of Roller:

-

45# Steel with quenching

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

7.5

-

Rolling thinckness:

-

0.5-1.5mm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Sussman

-

Voltage:

-

380V 50Hz or customized

-

Dimension(L*W*H):

-

About 5500*800*1200mm

-

Weight:

-

5000 kg

-

Feeding width:

-

60-250mm

-

Marketing Type:

-

cheap price

-

Material thickness:

-

0.5-1.5mm galvanized steel

-

Producting speed:

-

20-30m/min

-

Roller station:

-

About 13 stations

-

Hydraulic station:

-

7.5KW

-

Main Power:

-

11KW

-

Materia of cutting:

-

Cr12Mov

-

Hardness:

-

HRC58-62

-

Way Of Drive:

-

Chain driven

-

Material of Roller:

-

45# Steel with quenching

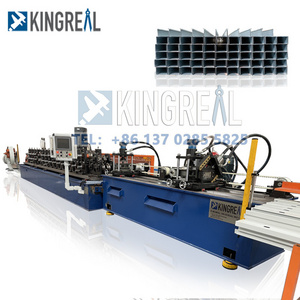

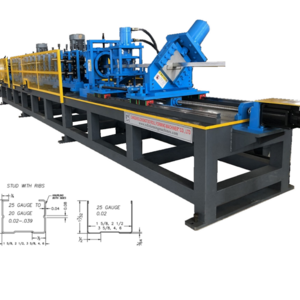

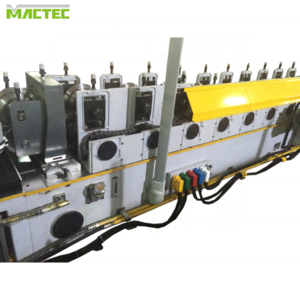

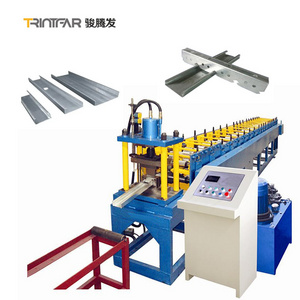

Light steel drywall system roll forming machine is the most popular machine and its product includes C U stud, track, furring channel, main channel, carrying channel, wall angle, corner angle, edge bead, shadow line wall angle, top hat, T bar machine, etc. Our machine has an extensive use in Drywall system, Ceiling system and Floor system. Thickness is normally 0.5-0.9mm or up to 1.2mm. Raw material could be: cold-rolled steel, Galvanized steel, high-tensile steel. In Drywall system and drywall partition system, we could provide roll forming machine as following: 1. Metal stud roll forming machine 2. Metal track roll forming machine 3. Main Channel roll forming machine 4. Omega hat furring channel roll forming machine 5. Conner bead (Angle bead) roll forming machine 6. T grid bar roll forming machine We could make roll forming machine with flying cut system to make working speed faster around 40m/min to 60m/min. And according to your drawing, we offer you double-row roll forming machine or triple-row roll forming machine that you could make two or three profiles in one machine, it reduces your machine cost and make it more affordable.

Coil inner Diameter: ¢460mm~520mm

Max out diameter of the coil: ¢800mm

Expansion: Manual with brake

Max Coil Width: 500mm

Motor Power: 7.5 kw forming system

Roller material: C45 steel

Base Frame: 300 H steel welded

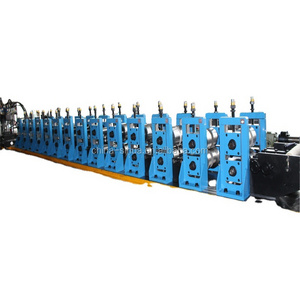

Roller Stations About 13 stations forming

Roller Material: 45# Steel with quenching

Shaft Material: 45# Steel Diameter 60mm shaft

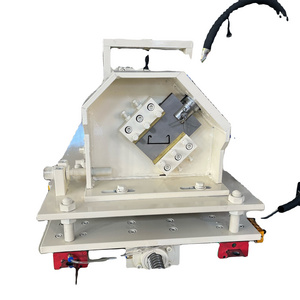

Cutting way: Stop to cut.

Oil pump statio:1set.

Hydraulic power: 4 kw hydraulic system.

Blade Material: CR12Mov with heat treatment HRC58-62.

Tolerance: +-1.5mm

Length & quantity measurement automatically;

Length & quantity controlled by PLC

Length inaccuracy can be amended easily.

Control panel: Button-type switch and touch screen

The language in the touch screen: English and Chinese

Unit of length: millimeter (switched on the control panel)

rolling plank. Therefore, please do the following things in your daily

1.The hydraulic tank must be filled with 32# or 46# hydraulic oil before using. The amount of oil is subject to the oil mark

2. Add and daub lube often to the outside parts. (Such as driving chain,Scissors, gears, rollers, )

3. Wipe the surface dust of roller often and particularly work outside. If you do not use it for long time ,you should daub

machine and lube in the roller surface and you need clean it when you use next time.

4. If the equipment does not use for long time, you should use plastics cloth or other articles to cover it and notice to avoid

rain and damp, especially electrical controlling box

5. Cutting device should add lube to the places where need lube to the request

6. Usually look into hydraulic station and the oil quantity of deceleration machine, you should add in time when oil quantity

shortage

7. Electrical components should be guaranteed to work in a dry environment, such as damp. Rain should continue to work after drying.

Before loading to the container, we will check the machine first

Second, make some protection on the machine, Such as, we will mpaint the coil on the roller and shaft, in case the roller and shast got corrosion and rusty during long time delivery

Third, we will make the plastic package on the easy damage parts, and fix all the parts into container by the steel wire rope, and ensure the machine will not damage when shaking on sea.

At last, we will take photos for customer when loading to container

Sussman Machinery has exported its equipment and machines to more than 80 countries over the world, such as Russia, India, Australia, Malaysia, Nigeria, Romania, South Africa,Mauritius,Mexico,etc. It has received excellent reputation. In the future, we are committed to better equipment and sales service and meeting customers' requirements when and where they need.