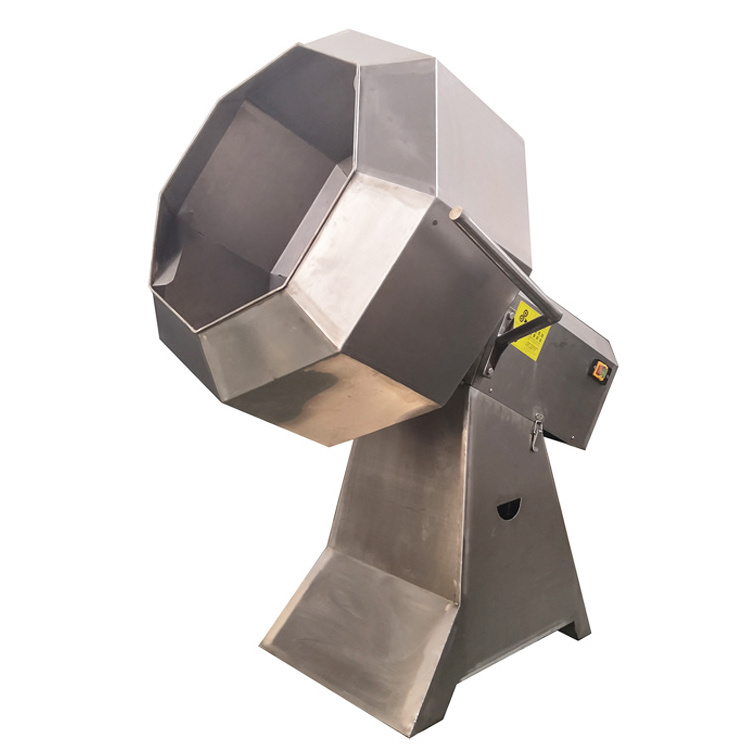

1.The washing&peeling machine is mainly composed of motor, peeling bucket, water spray, food grade stainless steel frame and

control button.

2.It can remove the potato skin in a short time as well as low breaking rate.

3.The machine is features of perfect appearance, easy operation, high efficiency and low breaking rate and high peeling ratio.

- Product Details

- {{item.text}}

Quick Details

-

Power:

-

customized

-

Dimension(L*W*H):

-

customized

-

Weight:

-

1111 KG

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

Name:

-

Potato Chips Production Line

-

Material:

-

304 Stainless Steel

-

Capacity:

-

300kg/H

-

Processing Type:

-

semi-automatic/automatic

-

Feature:

-

Save Energy

-

Advantages:

-

CE certificate

-

Package:

-

Wooden Case

-

Certification:

-

CE

Quick Details

-

Brand Name:

-

Hitrees

-

Place of Origin:

-

China

-

Voltage:

-

customized

-

Power:

-

customized

-

Dimension(L*W*H):

-

customized

-

Weight:

-

1111 KG

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

Name:

-

Potato Chips Production Line

-

Material:

-

304 Stainless Steel

-

Capacity:

-

300kg/H

-

Processing Type:

-

semi-automatic/automatic

-

Feature:

-

Save Energy

-

Advantages:

-

CE certificate

-

Package:

-

Wooden Case

-

Certification:

-

CE

Product Description

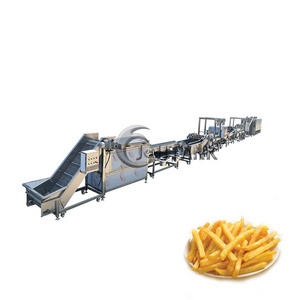

Our frozen french fries production line with fully automation or semi automation as your want, capacity from 50-3000 kg per hour. Mainly process: washing and peeling, cutting, blanching, de-water, frying, deoiling, freezing and packing. We have rich experience on frozen french fries production line.

|

No.

|

Item

|

Specification

|

Remarks

|

Function

|

|

1

|

Capacity

|

300 kg/h

|

Fresh Potato

|

Take the raw material into potato peeling machine

|

|

2

|

Processing Time

|

10 - 100 minute adjustable

|

Manual operation & frequecy control

|

Remove the potato skin with high efficiency and no big waste for the potato

|

|

3

|

Feeding Temperature

|

Room temperature

|

|

Cut potato into strips with good shape and high efficiency

|

|

4

|

Width of Conveyor Belt

|

750mm/650mm/1300mm

|

Wire belt/food grade PVC belt/quick-freezing machine belt

|

Cooking the fries before frying, save oil and keep good taste and beautiful shape

|

|

5

|

Blanching

|

80 - 100 ℃ adjustable

|

For screw peeling and blanching

|

Remove redundant water |

|

6

|

Blanching Required

|

1 ton/h

|

(0.4-0.7) Mpa

|

fry

|

|

7

|

Air Cooled

|

Water temperature cooling & freezing cooling

|

|

remove oil

|

|

8

|

Gas Consumption

|

25-30 L/h

|

Gas

|

Quick Freezing

|

|

9

|

Water Consumption

|

Water supply first time around 20 ton

|

Sink water supply

|

weight

|

|

10

|

Water Consumption

|

Approx 5 ton/h

|

Mainly engaged in washing and peeling

|

Package

|

Main Fetures:

1. Easy to operate.

2. High automation, large capacity.

3. High efficient, labor-saving, reduce labor time with higher capacity.

4. Small area occupation.

5.Good service after and before

2. High automation, large capacity.

3. High efficient, labor-saving, reduce labor time with higher capacity.

4. Small area occupation.

5.Good service after and before

Details Images

Potato Washing&Peeling Machine

Potato Cutting Machine

1.This potato cutting machine is made of food grade stainless steel.

2.It can cut potato into stick and slice after changing different knife.

3.This machine is high efficient with good performance.The whole machine is manufactured complying with hygiene requirement.

2.It can cut potato into stick and slice after changing different knife.

3.This machine is high efficient with good performance.The whole machine is manufactured complying with hygiene requirement.

Air bubble washing machine

1.The machine consist of motor, air pump, water pump, belt with food grade stainless steel frame.

2.It can remove the excess starch of potato sticks.Machine is easy to operate and maintain

2.It can remove the excess starch of potato sticks.Machine is easy to operate and maintain

Vibrating Machine

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Title goes here.

1.food grade stainless steel with four stainless steel baskets, temperature control panel and heating timer.

2.The water can be heated quickly.

3.It will be easy to frying the potatoes after blanching ,saving more oil and electric power.

4.Also the finished chips or french fries will be with beautiful color and best taste.

2.The water can be heated quickly.

3.It will be easy to frying the potatoes after blanching ,saving more oil and electric power.

4.Also the finished chips or french fries will be with beautiful color and best taste.

Dehydrating

1.This machine is made of stainless steel with removable basket.

2.the machine works in high speed and finish the dewatering process within very short time.

3.Before the frying, the potato sticks or slices will be removed surface water after blanching to save the oil and avoid oil splashing

2.the machine works in high speed and finish the dewatering process within very short time.

3.Before the frying, the potato sticks or slices will be removed surface water after blanching to save the oil and avoid oil splashing

Title goes here.

1.The frying machine is made of food grade stainless steel. 2.It consists of frying basket, electric heating pipe, control panel, motor, etc.

3. The heating temperature and frying time can be adjusted as per your requirement.

4. In addition, the machine adopt advanced technology , save oil and keep the food with good taste and color.

3. The heating temperature and frying time can be adjusted as per your requirement.

4. In addition, the machine adopt advanced technology , save oil and keep the food with good taste and color.

Freezing Machine

1.The machine is equipped with two individual compressor that come from France.

2.This machine can freeze fries into -18c after half cooking

3.It is also easy to operate and maintain.

2.This machine can freeze fries into -18c after half cooking

3.It is also easy to operate and maintain.

Packing machine

1.Chinese and English LCD touch screen

2.PLC control, easy to understand operation

3.High-precision electronic scale weighing, high precision

4.All stainless steel structure, easy to clean and corrosion resistant

5.Artificial bagging, photoelectric induction cutting

6.Vibrator feeding, high speed and high precision

Packing&Shipping

Company Introduction

We specialized to produce machines for food industry,include cooling & freezing equipment,bakery equipment,kitchen equipment,ice cream machines,processing lines for meat,dumplings,fishes,shrimps,fruits and vegetables,candies,chocolates and snack foods.Besides,we also provide site installation and commissioning services, and craft consultation services.

Our Advantage

Contact Us

Hot Searches