The 360-degree telescopic boom is 6 meters long, the rotating platform is fast, and the 4-meter leveling head can rotate and swing, leveling 24 square meters of concrete at a time.

The machine body rotates 360° and is designed with soft start and soft stop functions to ensure the stability of the leveling head.

- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

Concrete Floor Leveling Machine

-

Application:

-

Construction Project

-

Usage:

-

Building Coating

-

Power:

-

HONDA GX690/B&S 3864

-

Engine oil:

-

17L

-

Fuel oil:

-

1.2L-3.0L/H

-

Oil volume:

-

1.4L

-

Travel speed:

-

3.3km/h

-

Paving mode:

-

Auto+manual

-

Control effect:

-

Slab or Slope

Quick Details

-

Weight (KG):

-

880

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

SWANTECH

-

Product name:

-

Concrete Floor Leveling Machine

-

Application:

-

Construction Project

-

Usage:

-

Building Coating

-

Power:

-

HONDA GX690/B&S 3864

-

Engine oil:

-

17L

-

Fuel oil:

-

1.2L-3.0L/H

-

Oil volume:

-

1.4L

-

Travel speed:

-

3.3km/h

-

Paving mode:

-

Auto+manual

-

Control effect:

-

Slab or Slope

Laser Concrete Vibrating Screed Henan Concrete Laser Floor Screed

The

Laser Screed is used in large areas of concrete construction,

such as the modern industrial workshop, the large market, storage, airport, plaza, and so on. The Laser Screed can satisfy the construction requirements of large areas and high planeness and levelness.

1. Screed assembly is hydraulically controlled. Integrated with a laser system and computer control system, the machine will self-level and finish the screeding work with high efficiency.

2. The Laser transmitter which measures the elevation is independently located, so there is no worry about accumulative error. Compared with the traditional way, the construction joints will be greatly reduced, so the maintenance cost and slab use will be down greatly. For the complex floor which has a high requirement for drainage, the 3-D floor processing system can be used.

1. Screed assembly is hydraulically controlled. Integrated with a laser system and computer control system, the machine will self-level and finish the screeding work with high efficiency.

2. The Laser transmitter which measures the elevation is independently located, so there is no worry about accumulative error. Compared with the traditional way, the construction joints will be greatly reduced, so the maintenance cost and slab use will be down greatly. For the complex floor which has a high requirement for drainage, the 3-D floor processing system can be used.

Specification

|

Model

|

S-940

|

|

Power engine

|

HONDA GX690/B&S 3864

|

|

Type

|

Diesel engine,4 stroke

|

|

Power

|

23KW,3000r/min

|

|

Engine oil

|

17L

|

|

Fuel consumption rate

|

1.2L-3.0L/H

|

|

Oil volume

|

1.4L

|

|

Walking style

|

Wheeled

|

|

Drive System

|

Hydraulic motor four-wheel drive

|

|

Drive Control

|

Hydraulic drive

|

|

Travel speed

|

3.3km/h

|

|

Steering Control

|

Electronically controlled steering

|

|

Hydraulic fluid oil volume

|

30L

|

|

Vibrating method

|

Motor vibrating

|

|

Leveling thickness

|

3-30cm

|

|

Paving method

|

Strand paving

|

|

Vibration frequency

|

4500/min

|

|

Working width

|

3300mm

|

|

Paving method

|

Strand paving

|

|

Stranding power

|

Hydraulic Motor

|

|

Stimulation force

|

2000N

|

|

Work efficiency

|

300-500Square meters/h

|

|

Elevation control

|

Hydraulic cylinder

|

|

Control System

|

Laser emitter

|

|

Control Effect

|

Flat, slope, double slope

|

|

Wheelbase

|

710mm

|

|

Seat position

|

Mid-mounted

|

|

Dimension

|

3380*2500*1280mm

|

|

Weight

|

880KG

|

A variety of types for you to choose from:

Original imported laser leveling equipment, laser sweeping signal more accurate, flatter.

The integrated shell is more beautiful: dustproof, anti-concrete burst, and protects the internal equipment.

The integrated shell is more beautiful: dustproof, anti-concrete burst, and protects the internal equipment.

The construction area is more than 60 square meters per hour, and the daily workload is more than 4,000 square meters, which greatly improves the operation's efficacy.

B&S 31HP original imported engine, power surging winter one-touch start.

B&S 31HP original imported engine, power surging winter one-touch start.

The structure is light and flexible, and the machine weighs only 880 kg.B&S 23 horsepower engine with plenty of power

Electric vibration, electric steering, electric walking.

Electric vibration, electric steering, electric walking.

Product Description

Product use.

Common industrial plants, workshops, automated three-dimensional warehouses, large storage supermarkets, logistics centers, in the exhibition, wharves, container yards, yard yards, square, and residential ground.

Common industrial plants, workshops, automated three-dimensional warehouses, large storage supermarkets, logistics centers, in the exhibition, wharves, container yards, yard yards, square, and residential ground.

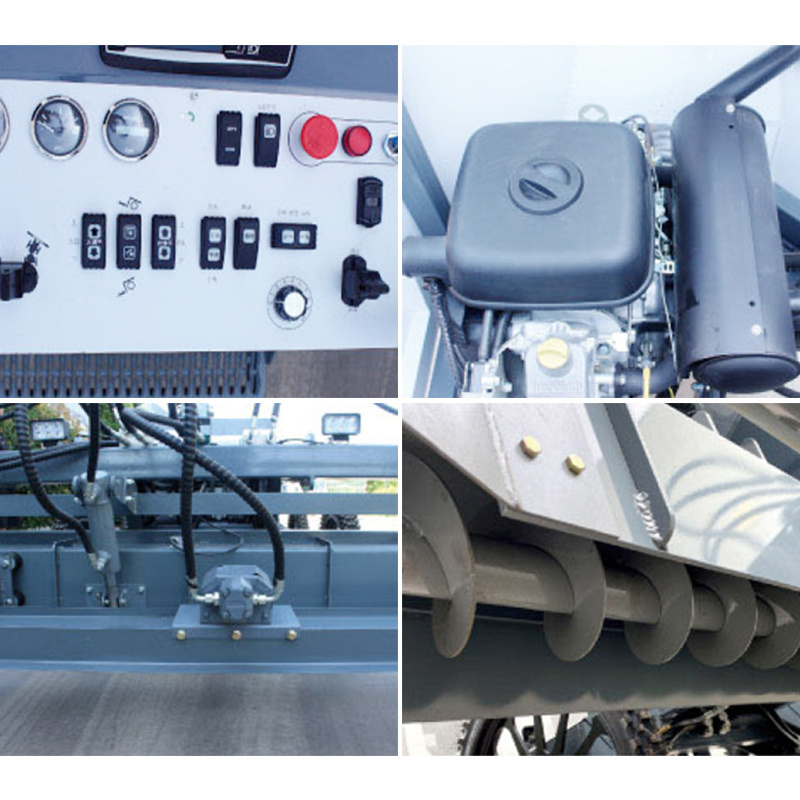

Details Images

The structure is light and flexible, and the machine weighs only 880Kg.

Electric vibration, electric steering, electric walking.

American Bailitone 23 horsepower engine with sufficient power.

Electric vibration, electric steering, electric walking.

American Bailitone 23 horsepower engine with sufficient power.

The machine comes with replenishment spiral, which can reduce the labor intensity of construction workers and improve the quality of construction.

The machine comes with fine adjustment function, which can better control the accuracy of concrete floor and improve the construction quality.

The main structural parts are all imported, the performance is more stable.

Intelligent operation panel, flexible control, single person can operate the construction.

The machine comes with fine adjustment function, which can better control the accuracy of concrete floor and improve the construction quality.

The main structural parts are all imported, the performance is more stable.

Intelligent operation panel, flexible control, single person can operate the construction.

The laser emitter is arranged independently to ensure that the ground elevation is consistent and no error is produced.

The stranded cage between the vibrating plate and scraper will turn over the excess concrete to sow one side, reducing the manpower and improving the speed.

Integrated leveling head, multiple processes are integrated together to improve efficacy and save labor.

The construction area is more than 400 square meters per hour, and the workload can be completed more than 3000 square meters per day, and the operation efficacy is greatly improved.

Present a set of spare tires

The stranded cage between the vibrating plate and scraper will turn over the excess concrete to sow one side, reducing the manpower and improving the speed.

Integrated leveling head, multiple processes are integrated together to improve efficacy and save labor.

The construction area is more than 400 square meters per hour, and the workload can be completed more than 3000 square meters per day, and the operation efficacy is greatly improved.

Present a set of spare tires

Packing & Delivery

1 unit was packed into an iron frame and then packed with 5 layers of corrugated carton. 4 strips reinforced the carton. the fix package guaranteed the machines were not damaged during transportation

Hot Searches