- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

HXCERAMIC

-

Color:

-

White

-

Size:

-

custom

-

Item:

-

zirconia ceramic parts

-

OEM:

-

yes

-

MOQ:

-

100PCS

-

Keywords:

-

Zro2 Ceramic Electric Clipper Blades

-

Density:

-

3.8g/cm3

Quick Details

-

Material:

-

Zirconia Ceramic

-

Place of Origin:

-

Guangdong, China

-

Model Number:

-

Zirconia ceramic

-

Brand Name:

-

HXCERAMIC

-

Color:

-

White

-

Size:

-

custom

-

Item:

-

zirconia ceramic parts

-

OEM:

-

yes

-

MOQ:

-

100PCS

-

Keywords:

-

Zro2 Ceramic Electric Clipper Blades

-

Density:

-

3.8g/cm3

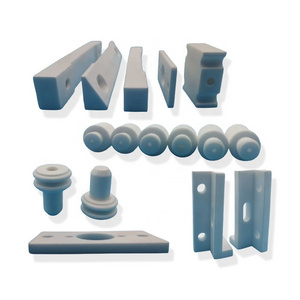

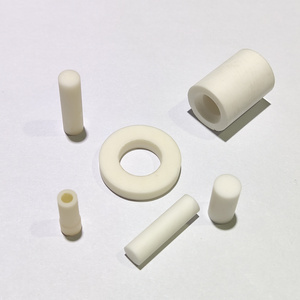

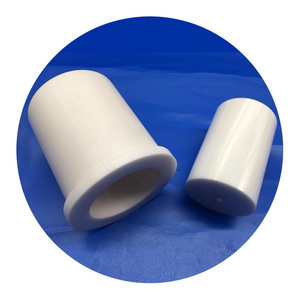

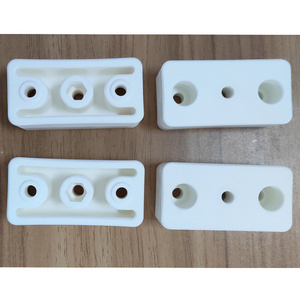

zirconia ceramic poiston

Features:

1.Use temperatures up to 2400°C

2. High density

3. High hardness

4. Low thermal conductivity

5. Chemical inertness

6. Resistance to molten metals

7. Good Wear resistance

8. High fracture toughness

We can supply the products according to customer's drawings, samples and performance requirement.

Zirconia ceramic are used in shaft , plunger, sealing structure, auto mobile Industrial, oil drilling equipment, Insulation parts in electrical equipment , ceramic knife, ceramic hair clipper spare parts, with high density, bending strength and breaking tenacity.

| Performance | ||||

| Item | Unit | 99 Al 2 O 3 | Zirconia | |

| Physical Characteristics | Bulk density | g/cm 3 | 3.9 | 6.05 |

| Water absorption | % | 0 | 0 | |

| Mechanical Characteristics |

Flexural strength |

Mpa | 360 | 1000 |

| Hardness Vickers | Gpa | 15.6 | 89 | |

| Elastic modulus | Gpa | 370 | 200 | |

| Poisson’s ratio | - | 0.23 | 0.31 | |

| Thermal Characteristics | Linear expansion coefficient | (20-500 0 C) 10 -6 / 0 C | 8 | 10 |

| Thermal conductivity | w/(m.k) | 32 | 2.5 | |

| Specific Heat | *10 -3 J/(kg*K) | 0.9 | 0.5 | |

| Processing technology | ||||

| Process range (mm) | ||||

| Outside Diameter | 1---300 | |||

| Inside Diameter | 0.5---300 | |||

| Length | 0.5---1200 | |||

| Accuracy of working (mm) | ||||

| Perpendicularity | 0.01 | |||

| Concentricity | 0.01 | |||

| Roundness | 0.005 | |||

| Straightness | 0.005 | |||

| Parallelism | 0.01 | |||

| Planeness | 0.005 | |||

| Roughness | 0.05 | |||

| Fit clearance | 0.005 | |||