- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

NO

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

sinograce

-

Model Number:

-

SA-901

-

Type:

-

liquid coating, paver sealer

-

Product name:

-

Ultra Look Seale

-

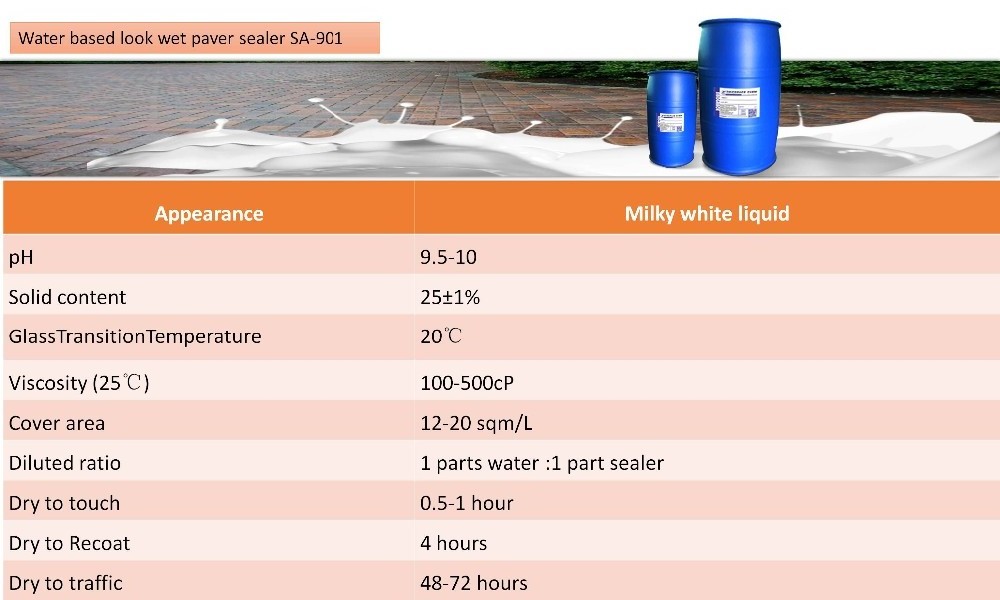

Glass Transition Temperature:

-

20℃

-

Solid content:

-

25%

-

Diluted ratio:

-

1 parts water :1 part sealer

-

PH:

-

9-9.5

-

Dry to touch:

-

0.5-1 hour

-

Dry to Recoat:

-

4 hours

-

Dry to traffic:

-

48-72 hours

-

Keywords:

-

modified silicone sealer

Quick Details

-

CAS No.:

-

NO

-

Other Names:

-

Silicone Sealant

-

MF:

-

NO

-

EINECS No.:

-

NO

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

sinograce

-

Model Number:

-

SA-901

-

Type:

-

liquid coating, paver sealer

-

Product name:

-

Ultra Look Seale

-

Glass Transition Temperature:

-

20℃

-

Solid content:

-

25%

-

Diluted ratio:

-

1 parts water :1 part sealer

-

PH:

-

9-9.5

-

Dry to touch:

-

0.5-1 hour

-

Dry to Recoat:

-

4 hours

-

Dry to traffic:

-

48-72 hours

-

Keywords:

-

modified silicone sealer

SA- 901 Acrylic Modified Silicone Hydrophobic Sealer

Description

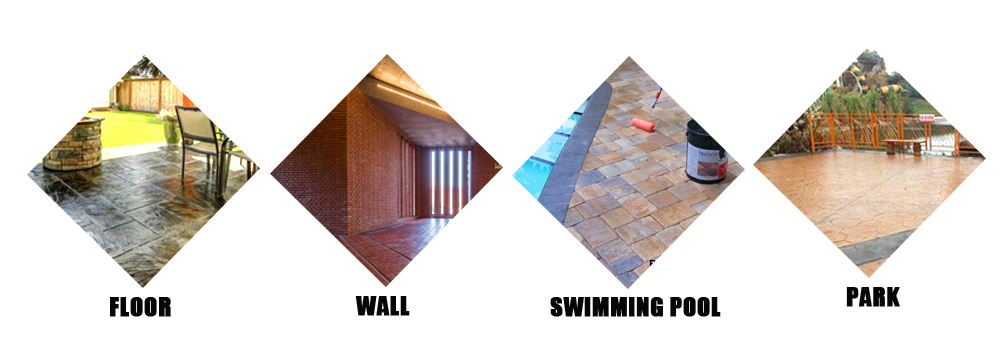

SA-901 is water based acrylic modified silicone sealer, which penetrates into the pavers and provides a hydrophobic coating. It can inhibit the algae and mold with good abrasion resistant.

Type

Acrylic modified silicone dispersion

| Type Acrylic modified silicone dispersion |

Storage and Handling

l Available in 200 kg/ barrel or 25 kg/ barrel

l Store products in tightly closed original containers at 5-40℃

l Shelf life: 9 months from delivery date According to non-dangerous goods transport

How To Use

1. Pressure Washing: Pressure washes the area to be sealed, ensuring that surfaces are clean and free of oil, efflorescence, laitance or contaminants prior to beginning the sealing process. Remove at least 1 to 2 inches of the old joint sand so new coarse sand can be replaced between the paver joints.

2. Rinsing: Rinse the pavers with water. If any acids/cleaners were used during the cleaning phase, make sure that the acids and cleaners are thoroughly rinsed before sealing.

3 . Application: SA-90 1 can be applied even though the pavers are damp. It cannot be applied to pavers in standing water, as the sealer will not cure and stabilize the joint sand. Dilute 1 part water and 1 part sealer for the flood coat and top coat. We recommend multiple coats for extremely absorbent pavers. A slip guard additive may be necessary with additional coats. Using our battery operated pail pump system or pump sprayer, uniformly apply a flood coat of sealer for joint stabilization. Hold sprayer tip 10” – 12” from the paver surface (avoid overspray on adjacent surfaces, rinse any overspray with water). Sealer appears white when applied but dries crystal clear. Make sure to apply sealer consistently to prevent blotching. (Back rolling is recommended for consistency) Pavers with polymeric sand, we recommend two even consistent coats of sealer without flooding the paver joints. Use a leaf blower to blow out any excessive sealer that puddles in the paver joints or low lying areas with textured pavers and or natural stone. Excess sealer may be stored for future use.