- Product Details

- {{item.text}}

Quick Details

-

Thermal Conductivity:

-

≤0.165, 0.085(W/m.k)@400℃

-

Thickness:

-

5~50mm

-

Width:

-

400/600mm

-

Length:

-

600/900/1000mm

-

Working Temperature:

-

1100℃~1350℃

-

Shrinkage (1800℉, 3h):

-

1.1

-

Place of Origin:

-

Shandong, China

-

Model Number:

-

ceramic fiber board

-

Brand Name:

-

Jucos

-

Product name:

-

Ceramic fiber board

-

Color:

-

White

-

Bulk Density:

-

280-320g/cm3

-

permanent Linear Change:

-

-3%@1000℃*3hrs

-

AL2O3:

-

43%

-

AL2O3+SIO3:

-

96%

-

Cold Crushing Strength:

-

0.2MPa

-

Specification Temp:

-

1260℃

-

Working Temp:

-

1100℃

Quick Details

-

Chemical Composition:

-

Al2O3+SiO2

-

Ultimate Strength (≥ MPa):

-

0.040~0.075MPa

-

Fiber Diameter:

-

3.5umm

-

Thermal Conductivity:

-

≤0.165, 0.085(W/m.k)@400℃

-

Thickness:

-

5~50mm

-

Width:

-

400/600mm

-

Length:

-

600/900/1000mm

-

Working Temperature:

-

1100℃~1350℃

-

Shrinkage (1800℉, 3h):

-

1.1

-

Place of Origin:

-

Shandong, China

-

Model Number:

-

ceramic fiber board

-

Brand Name:

-

Jucos

-

Product name:

-

Ceramic fiber board

-

Color:

-

White

-

Bulk Density:

-

280-320g/cm3

-

permanent Linear Change:

-

-3%@1000℃*3hrs

-

AL2O3:

-

43%

-

AL2O3+SIO3:

-

96%

-

Cold Crushing Strength:

-

0.2MPa

-

Specification Temp:

-

1260℃

-

Working Temp:

-

1100℃

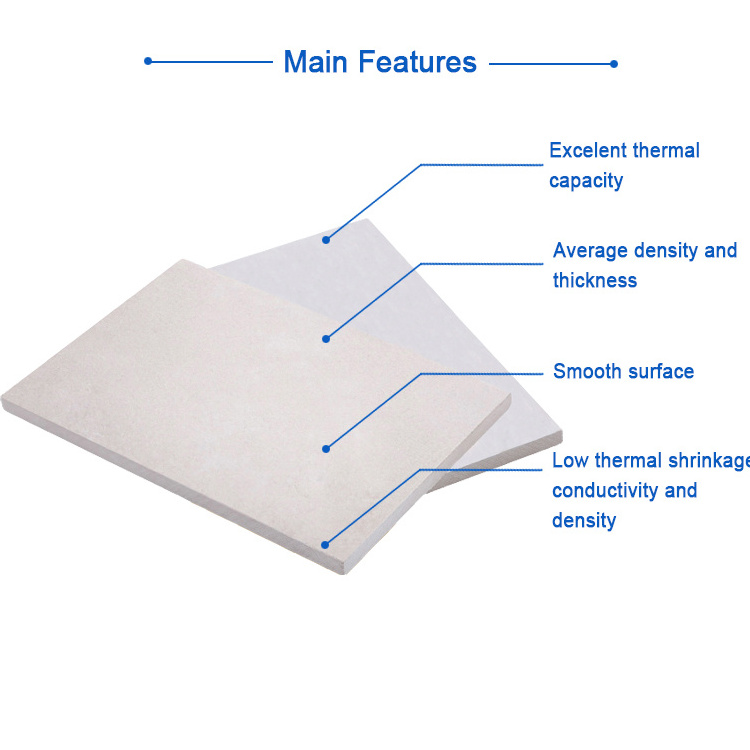

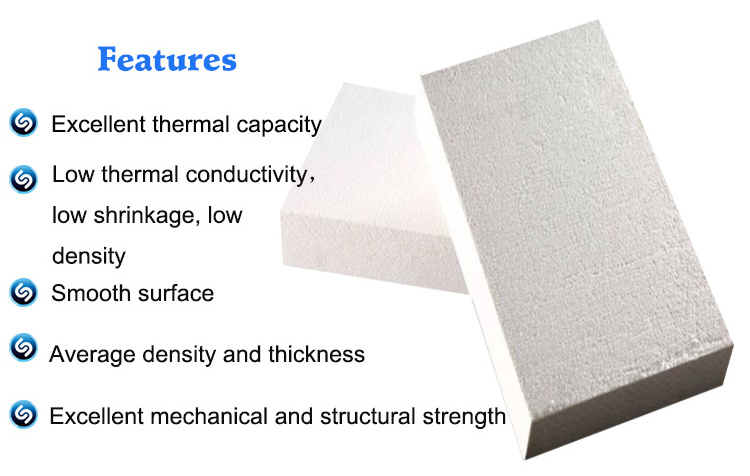

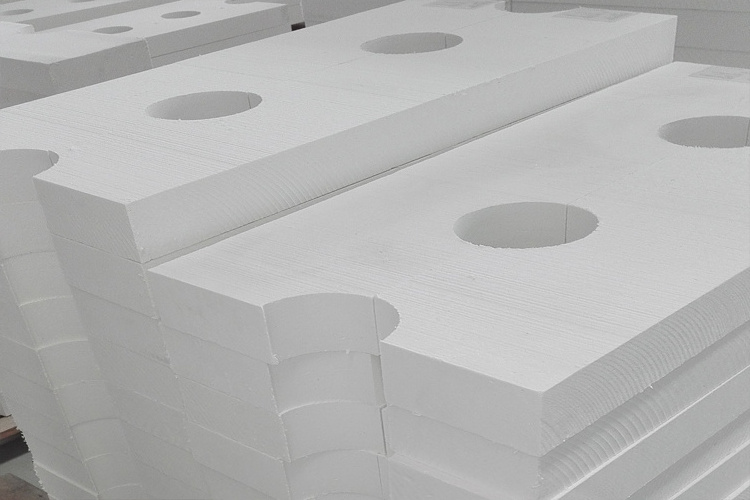

Description Of Ceramic Fiber Board

Ceramic fiber board is a lightweight refractory material processed with alumina-silica fibers for applications at temperatures up to 1430C. it manufactured and designed for the thermal applications requesting high demands on rigidity, the thermal insulation properties and abrasion resistance of ceramic fiber board have been further improved due to the higher density. Ceramic fiber board is a vacuum formed product that resists higher gas velocities than ceramic fiber blanket. It is ideal for furnace, boiler duct and stack lining thanks to its low thermal conductivity and low heat storage, which makes the shorter cycles times and quicker access for maintenance in the industrial furnaces possible.

Specifications Of Product

Alumina contents range from 40% to 45%

Widely used throughout metallurgical industry

Physical And Chemical Indicators Of Product

|

Brand

Properties |

|

ST BOD

|

GC BOD

|

HZ BOD

|

TP64 BOD

|

TP74 BOD

|

|||||

|

Specification Temp. (℃)

|

|

1260

|

1260

|

1430

|

1600

|

1700

|

|||||

|

Working Temp (℃)

|

|

1000

|

1100

|

1350

|

1450

|

1550

|

|||||

|

Bulk Density (kg/m3)

|

|

280-400

|

280-400

|

280-400

|

400-500

|

450-500

|

|||||

|

(%)

Linear Shrinkage after Heating |

|

-3.0

(1000℃) @24H |

-3.0

(1100℃) @24H |

-3.0

(1350℃) @24H |

-2.0

(1450℃) @8H |

-2.0

(1550℃) @8H |

|||||

|

(w/m.k)

Thermal Conductivity |

|

0.085(400℃)

0.132(800℃) 0.190(1000℃) |

0.085(400℃)

0.132(800℃) 0.190(1000℃) |

0.085(400℃)

0.132(800℃) 0.180(1000℃) |

0.135(400℃)

0.182(800℃) 0.230(1000℃) |

0.185(400℃)

0.232(800℃) 0.280(1000℃) |

|||||

|

(MPa) Tensile Strength

|

|

0.2

|

0.2

|

0.2

|

0.3

|

0.3

|

|||||

|

(%)

Chemical Composition |

Al2O3

|

38

|

42

|

34

|

64

|

75

|

|||||

|

|

Al2O3+SiO2

|

96

|

98

|

-

|

99

|

99

|

|||||

|

|

ZrO2

|

-

|

-

|

15-17

|

-

|

-

|

|||||

|

|

Fe2O3

|

1.0

|

0.5

|

0.2

|

0.2

|

0.2

|

|||||

|

|

Na2O+K2O

|

0.5

|

0.3

|

0.2

|

0.2

|

0.2

|

|||||

|

Size(mm)

|

|

LENGTH*WIDTH*THICKNESS

900*600*20/25/30/40/50,1000*500*20/25/30/40/50,1000*600*20/25/30/40/501200*1000*20/25/30/40/50,1200*600*20/25/30/40/50 |

|

|

|

|

|||||

Industry Application

Packing &Shipping

Hot Searches