- Product Details

- {{item.text}}

Quick Details

-

Table Travel (Y) (mm):

-

550

-

Dimension(L*W*H):

-

4520*3960*3340

-

Weight (T):

-

10.5 T

-

Range of Spindle Speed(r.p.m):

-

1 - 10000 r.p.m

-

Spindle Motor Power(kW):

-

11

-

Max. Table Load(kg):

-

350 kg

-

Feed Speed(mm/min):

-

1 - 15000 mm/min

-

Place of Origin:

-

Liaoning, China

-

Brand Name:

-

DRC MACHINERY

-

Voltage:

-

380

-

Marketing Type:

-

Hot Product 2024

-

Number of Axis:

-

5, 12

-

Product name:

-

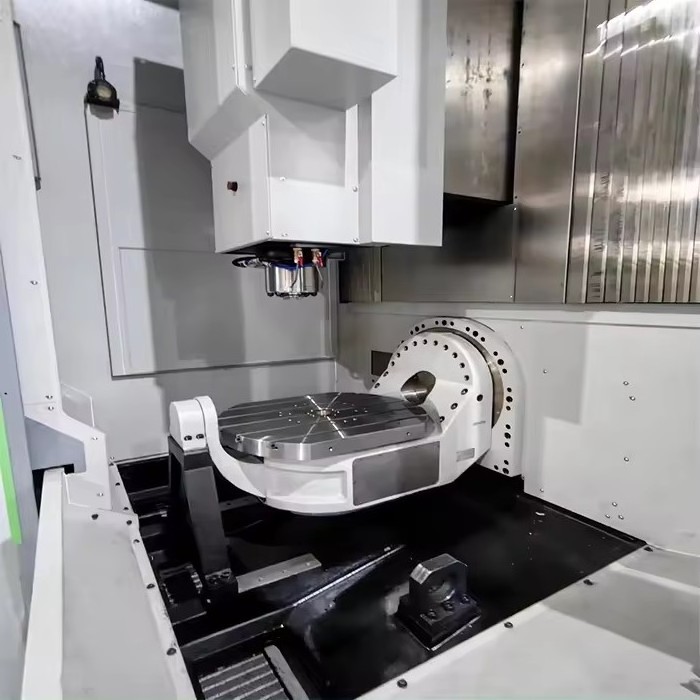

CNC 5-Axis Milling Machine

-

Control system:

-

FANUC GSK SIEMENS

-

Application:

-

Metal CNC Vertical Machining Center

-

Precision CNC Machine Centre:

-

High Precision Mini Machining Center

-

Spindle taper:

-

BT50 Vertical machine center

-

Table size:

-

600mm CNC Vertical Machining Center

Quick Details

-

Table Size (mm):

-

1360x700

-

Number of Axes:

-

5

-

Table Travel (X) (mm):

-

650

-

Table Travel (Y) (mm):

-

550

-

Dimension(L*W*H):

-

4520*3960*3340

-

Weight (T):

-

10.5 T

-

Range of Spindle Speed(r.p.m):

-

1 - 10000 r.p.m

-

Spindle Motor Power(kW):

-

11

-

Max. Table Load(kg):

-

350 kg

-

Feed Speed(mm/min):

-

1 - 15000 mm/min

-

Place of Origin:

-

Liaoning, China

-

Brand Name:

-

DRC MACHINERY

-

Voltage:

-

380

-

Marketing Type:

-

Hot Product 2024

-

Number of Axis:

-

5, 12

-

Product name:

-

CNC 5-Axis Milling Machine

-

Control system:

-

FANUC GSK SIEMENS

-

Application:

-

Metal CNC Vertical Machining Center

-

Precision CNC Machine Centre:

-

High Precision Mini Machining Center

-

Spindle taper:

-

BT50 Vertical machine center

-

Table size:

-

600mm CNC Vertical Machining Center

Product Description

5 Axis Cnc Machining Center DRC550 5 Axis Cnc Milling And Boring Machine Vertical Cnc 5 Axis Milling Machine

The overall design of the machine tool uses finite element analysis. The casting box is designed with a five-point support structure and is integrally formed using resin sand technology, which minimizes structural defects such as stress deformation and processing heat deformation of the machine tool. The material is made of HT300 high-strength cast iron, which has been tempered twice and artificially aged to effectively ensure the overall accuracy and quality of the machine tool and product quality.

The machine tool adopts a BC structure design with a three-axis stroke of 650/450/475mm, which effectively increases the maximum space for five-axis simultaneous processing and reduces the possibility of component collisions during rotation.

The maximum moving speed of the machine tool can reach 24/24/24m/min (X/Y/Z), and the spindle speed can reach 15000rpm. The entire process uses roller guide rails and Taiwanese brand ground double-nut ball screws, and both ends of the screw are pre-stretched. , eliminate the loss of precision caused by thermal elongation, and use precision screw support bearings to form a stable and high-rigidity mechanical transmission system. Improves the rigidity and stability during processing, and improves the machine tool's rapid response capability,

The spindle uses a 15/24kw high-speed motor, which can provide a speed of 15,000rpm/min and a maximum torque of 140Nm. It is supported by high-precision angular contact ball bearings, so that the spindle obtains high rigidity and extremely high spindle rotation accuracy.

The machine tool comes standard with a 30-position tool magazine, the tool changing time is stable at 7 seconds, and the operation is safe and reliable.

The linear axes all adopt roller linear guides, which have high precision and large load capacity. The friction force is low, which reduces the crawling phenomenon of the machine tool at low speed, and the positioning accuracy is good, while obtaining high dynamic response characteristics.

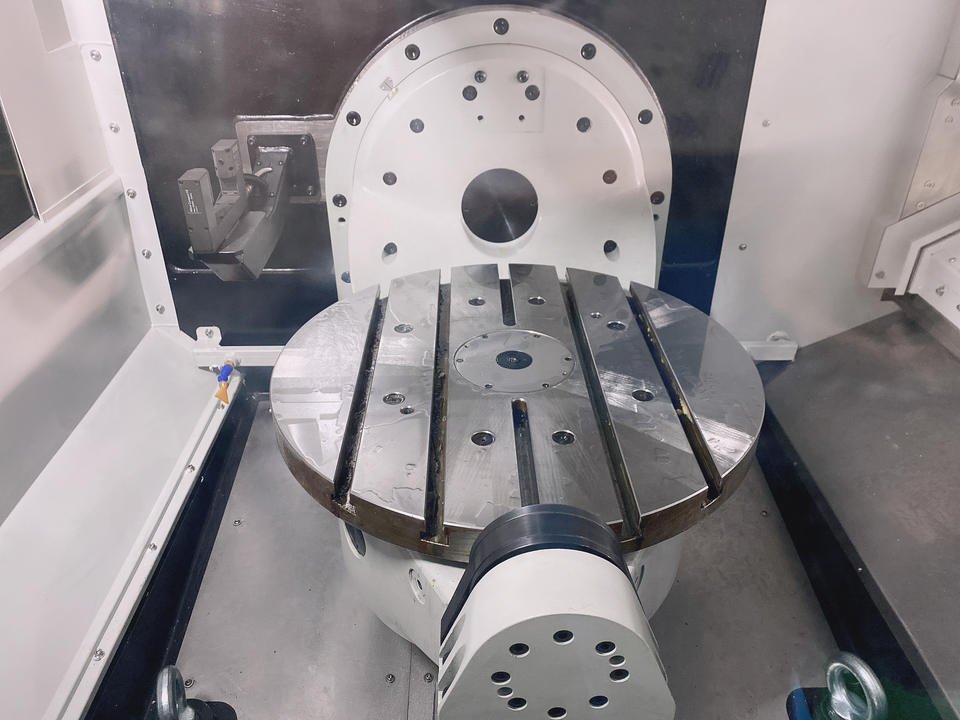

The cradle uses a DD motor rotary table with high acceleration, high torque, high precision, and zero backlash torque motor; it has a built-in powerful braking system, uses large-diameter, high-precision, and high-rigidity bearings inside, and uses two-point support in the B-axis direction. , The maximum load-bearing capacity of the turntable is 300Kg. The C-axis can rotate at high speed and index continuously. With the support of the spindle orientation function, it supports high-speed rotating turning.

Specification

|

Working Area

|

MX500

|

|

|

Table dimension

|

D630x500

|

mm

|

|

Distance spindle nose – table

|

140-615

|

|

|

X travel

|

650

|

|

|

Y travel

|

650

|

|

|

Z travel

|

475

|

|

|

B travel

|

±110

|

°

|

|

C travel

|

360

|

°

|

|

Feed Drive

|

|

|

|

Rapid Traverse X/Y/Z

|

30/30/30

|

m/min

|

|

Main spindle

|

|

|

|

Spindle nose

|

HSK A63

|

|

|

Power

|

15

|

kW

|

|

Torque

|

85/100

|

Nm

|

|

Max. spindle Speed

|

18,000

|

rpm

|

|

Magazine

|

|

|

|

Number Tool Stations

|

30

|

pcs

|

|

Shank diameter

|

HSK A63

|

mm

|

|

Positioning Accuracy according to

VDI 3441 |

|

|

|

Accuracy of positioning in X/Y/Z Axes

(Indirect Measuring System) |

≤ 8 /8 / 10

|

µm

|

|

Accuracy of repeatability in X/Y/Z Axes

(Indirect Measuring System) |

≤ 6 /6 / 8

|

µm

|

|

Hydraulic Unit

|

|

|

|

Tank Capacity

|

5

|

l

|

|

Pressure, max.

|

75

|

bar

|

|

Coolant Equipment

|

|

|

|

Coolant tank capacity

|

200

|

l

|

|

Chip conveyor capacit

|

180

|

l

|

|

Pump Power

|

0,53

|

kW

|

|

Pump nominal flow rate at 5 bar

|

24

|

l/min.

|

|

Electrical Connection

|

|

|

|

Installed Power, max

|

50

|

kVA

|

|

Voltage

|

400

|

V

|

|

Frequency

|

50/60

|

Hz

|

|

Fusing (slow-blowing) according to VDE 0100

|

50

|

A

|

|

Allowed Voltage Fluctuation at 400 V

|

+ 10

|

%

|

|

Acceptance

|

|

|

|

Machine Acceptance Test

|

according to VDI 3441

|

|

|

Pneumatics

|

|

|

|

Air Pressure

|

6

|

bar

|

|

Air consumption

|

15

|

m3/h

|

|

Environment Conditions

|

|

|

|

Room Temperature

|

+ 15 to + 35

|

°C

|

|

Max. relative air humidity

|

75

|

%

|

|

Max. Installation Height above msl

|

1000

|

m

|

|

Weights

|

|

|

|

Net weight of the machine with chip conveyor

|

approx. 7500

|

kg

|

|

Dimensions

|

|

|

|

Machine with Chip Conveyor

L x B x H discharge of chips from the right side |

approx. 2850 x 2300 x 2750

|

mm

|

Hot Searches