- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

1kg/plastic box

-

Flux Content:

-

0

-

Place of Origin:

-

Anhui,China

-

Brand Name:

-

Xin Xin

-

Model Number:

-

XX-BAg

-

Application:

-

welding for copper alloys, stainless steel, etc

-

Feature:

-

Excellent Welding Performance

-

Color:

-

Silver Grey

-

Package:

-

plastic box

-

OEM:

-

Accept

-

Usages:

-

Welding Material

-

Sample:

-

Avaiable

-

MOQ:

-

100kg

-

Use type:

-

Mig Torch

-

Advantage:

-

Excellent Ductility

Quick Details

-

Material:

-

Ag,Cu,Zn, AgCuZn

-

Diameter:

-

1.6-6mm

-

Melting Point:

-

655℃

-

Weight:

-

1kg/plastic box

-

Flux Content:

-

0

-

Place of Origin:

-

Anhui,China

-

Brand Name:

-

Xin Xin

-

Model Number:

-

XX-BAg

-

Application:

-

welding for copper alloys, stainless steel, etc

-

Feature:

-

Excellent Welding Performance

-

Color:

-

Silver Grey

-

Package:

-

plastic box

-

OEM:

-

Accept

-

Usages:

-

Welding Material

-

Sample:

-

Avaiable

-

MOQ:

-

100kg

-

Use type:

-

Mig Torch

-

Advantage:

-

Excellent Ductility

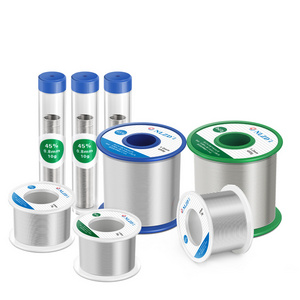

Electrical Equipment Can Be Welded with 25% Silver Tin Solder Welding Wire

The following are general purpose brazing alloys, suitable to join easily a wide range of ferrous and non ferrous base materials (iron, steel, stainless steel, copper, brass, etc.).

Continuous service operating temperatures of joints brazed with these alloys range up to approx 200 ° C.

When joining stainless steel in wet environments, in order to avoid failure of the joint due to interfacial corrosion, it is recommended to use zinc-free alloys (Ag60Sn/1), or alloys with Nickel additions.

Available in many different presentation forms (rods, flux-coated rods, wires, strips, rings, preforms, pastes and powders), these alloys are very free flowing, ductile and strong.

|

Code |

Composition % |

Melting Range |

Density |

Tensile |

Standard |

|||||||

|

|

Ag |

Cu |

Zn |

Sn |

Si |

℃ |

g /cm ³ |

K g/mm ² |

ISO17672 |

EN1044 |

AWSA5.8 |

|

|

Ag25Sn |

25 |

40 |

33 |

2 |

- |

680-760 |

8 . 8 |

48 |

Ag 125 |

AG 108 |

BAg-37 |

|

|

Ag65 |

65 |

20 |

15 |

- |

- |

670-720 |

9 . 6 |

41 |

Ag265 |

-- |

BAg-9 |

|

|

Ag45 |

45 |

30 |

25 |

- |

- |

665-745 |

9 . 1 |

42 |

Ag 245 |

|

BAg-5 |

|

|

Ag44 |

45 |

30 |

26 |

- |

- |

675-735 |

9 . 1 |

51 |

Ag 244 |

AG 203 |

-- |

|

|

Ag40 |

40 |

30 |

30 |

- |

- |

660-720 |

9 . 1 |

46 |

-- |

-- |

-- |

|

|

Ag35 |

35 |

32 |

33 |

- |

- |

685-755 |

9 |

48 |

Ag235 |

-- |

BAg-35 |

|