- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

VOSTOSUN

-

Dimension(L*W*H):

-

12500X2450X4000

-

Weight:

-

100 KG

-

Marketing Type:

-

New Product 2023

-

Model:

-

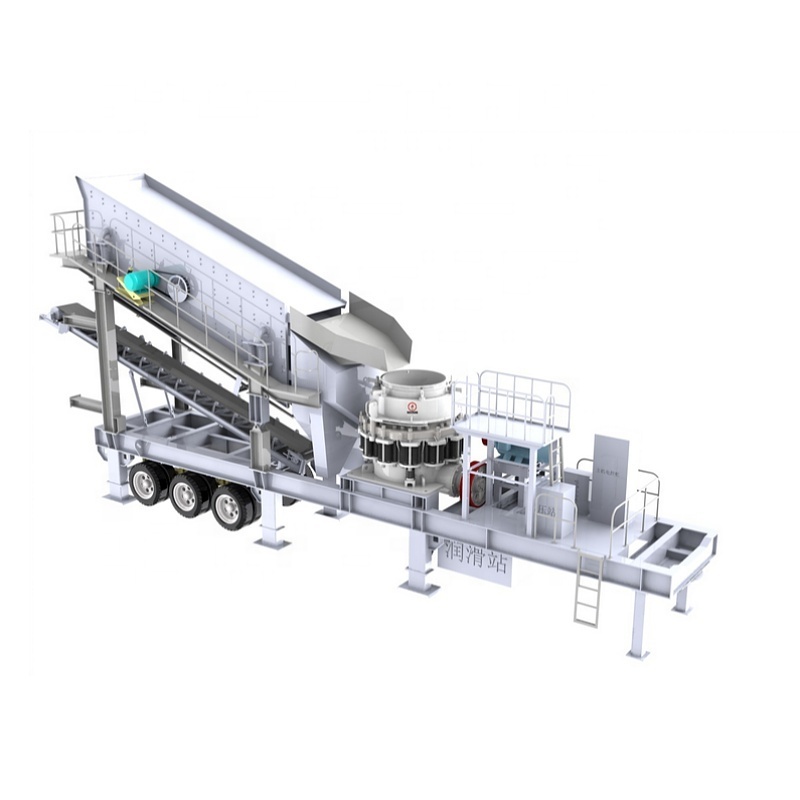

VSC-3 F1010

-

Crusher:

-

6VX1010

-

Feeder:

-

ZSW300X90

-

Screen:

-

3YA1548

-

Magnetic Separator:

-

RCYD(C)-8

-

Number of Axles:

-

3

-

Capacity (t/h):

-

100-200

-

Dimension:

-

18150x4400x7320

Quick Details

-

Type:

-

Mobile crusher plant

-

Application:

-

Mining

-

Capacity(t/h):

-

50-400t/h

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

VOSTOSUN

-

Dimension(L*W*H):

-

12500X2450X4000

-

Weight:

-

100 KG

-

Marketing Type:

-

New Product 2023

-

Model:

-

VSC-3 F1010

-

Crusher:

-

6VX1010

-

Feeder:

-

ZSW300X90

-

Screen:

-

3YA1548

-

Magnetic Separator:

-

RCYD(C)-8

-

Number of Axles:

-

3

-

Capacity (t/h):

-

100-200

-

Dimension:

-

18150x4400x7320

Introduction

The concept of mobile and semi-mobile crushers has been around for a long time, but for years many machines were very heavy and moving them required thoughtful planning. As result, the crushers that were supposed to be mobile were seldom relocated and tended

stay put in permanent facilities.

Nowadays, the weight of mobile crushers has decreased considerably, and crushing as well as mobility properties improved notably.Mobility is not substitute for effective crushing anymore, and tracked/wheeled mobile crushers meet the same basic criteria as

stationary plants.

The ability to crush also the largest lumps to the desired cubicity at the desired rate are all ‘must-have’ rather than ‘nice-to-have’ attributes. The basic components of mobile crushers are almost the same as for stationary ones, but with the added advantage of complete mobility – even up slopes as steep as 1:10 incline.

Application of Mobile Crusher:

The Mobile Crusher is applied to multistage crush large materials, and then screen the discharges according to their different specifications. The whole set plants is widely used to mine, building material, highway, rail way and hydropower industries, etc.,finish crushing and screening operations at one time, produce required size and output for consumers.

Mobile crushers are often referred to as ‘mobile crushing plants’. They are track-mounted or wheel-mounted crushing machines which, thanks to their mobility, can maximize productivity and reduce operating costs – while increasing safety and reducing environmental impact.

The concept of mobile and semi-mobile crushers has been around for a long time, but for years many machines were very heavy and moving them required thoughtful planning. As result, the crushers that were supposed to be mobile were seldom relocated and tended

stay put in permanent facilities.

Nowadays, the weight of mobile crushers has decreased considerably, and crushing as well as mobility properties improved notably.Mobility is not substitute for effective crushing anymore, and tracked/wheeled mobile crushers meet the same basic criteria as

stationary plants.

The ability to crush also the largest lumps to the desired cubicity at the desired rate are all ‘must-have’ rather than ‘nice-to-have’ attributes. The basic components of mobile crushers are almost the same as for stationary ones, but with the added advantage of complete mobility – even up slopes as steep as 1:10 incline.

Application of Mobile Crusher:

The Mobile Crusher is applied to multistage crush large materials, and then screen the discharges according to their different specifications. The whole set plants is widely used to mine, building material, highway, rail way and hydropower industries, etc.,finish crushing and screening operations at one time, produce required size and output for consumers.

Technical data:

1.Mobile Jaw Crusher Plant

Popular mobile jaw crushers are generally utilized as primary crushers that reduce the material to smaller sized for further

processing.

Popular mobile jaw crushers are generally utilized as primary crushers that reduce the material to smaller sized for further

processing.

2. Mobile Impact Crusher Plant

Mobile impact crushers are wide-ranging crushing machines that fall into two distinctive categories

according to the crushing technology they use. Mobile HSI crushers have a horizontal impact crushing unit and they are used as primary, secondary, or tertiary crushers. Mobile VSI crushers, in turn, are equipped with vertical shaft impact crushing unit, and they are extremely efficient in the last stage of the crushing process, producing precisely shaped cubical end products.

according to the crushing technology they use. Mobile HSI crushers have a horizontal impact crushing unit and they are used as primary, secondary, or tertiary crushers. Mobile VSI crushers, in turn, are equipped with vertical shaft impact crushing unit, and they are extremely efficient in the last stage of the crushing process, producing precisely shaped cubical end products.

3.Mobile Cone Crusher Plant

Mobile cone crushers are traditionally used as secondary, tertiary, and quaternary crushers. However, if the grain size of the processed material is small enough by nature, then they can also operate at the first stage of the crushing process.

4.Combined Mobile Crushing Plant

The combined mobile crusher plant is equipped with an vibrating feeder, primary or secondary crusher and an effective vibrating screen and related belt conveyors. In addition to the space-saving installation, the manufacturer offers a clearly increased productivity to the operator. Furthermore, the power consumption will be largely decreased by using the combined mobile crusher plant.

Hot Searches