- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

YINGYONG

-

Dimension(L*W*H):

-

820x520x1270

-

Weight:

-

7.8 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

VSI crusher

-

After sale Service:

-

Life-long Service

-

Color:

-

Customizable

-

Product name:

-

Widely-used Mining Equipment

-

Installation:

-

Engineer Guide

-

Spare parts supply:

-

Time

-

Test&Installation:

-

Senior Professional Engineers Assigned

-

Max feeding size:

-

200-1020mm

-

Price:

-

Competetive (can Discuss

Quick Details

-

Application:

-

Mining

-

Capacity(t/h):

-

60-260

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

YINGYONG

-

Dimension(L*W*H):

-

820x520x1270

-

Weight:

-

7.8 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

VSI crusher

-

After sale Service:

-

Life-long Service

-

Color:

-

Customizable

-

Product name:

-

Widely-used Mining Equipment

-

Installation:

-

Engineer Guide

-

Spare parts supply:

-

Time

-

Test&Installation:

-

Senior Professional Engineers Assigned

-

Max feeding size:

-

200-1020mm

-

Price:

-

Competetive (can Discuss

VSI crusher

NO . 1 Introduction

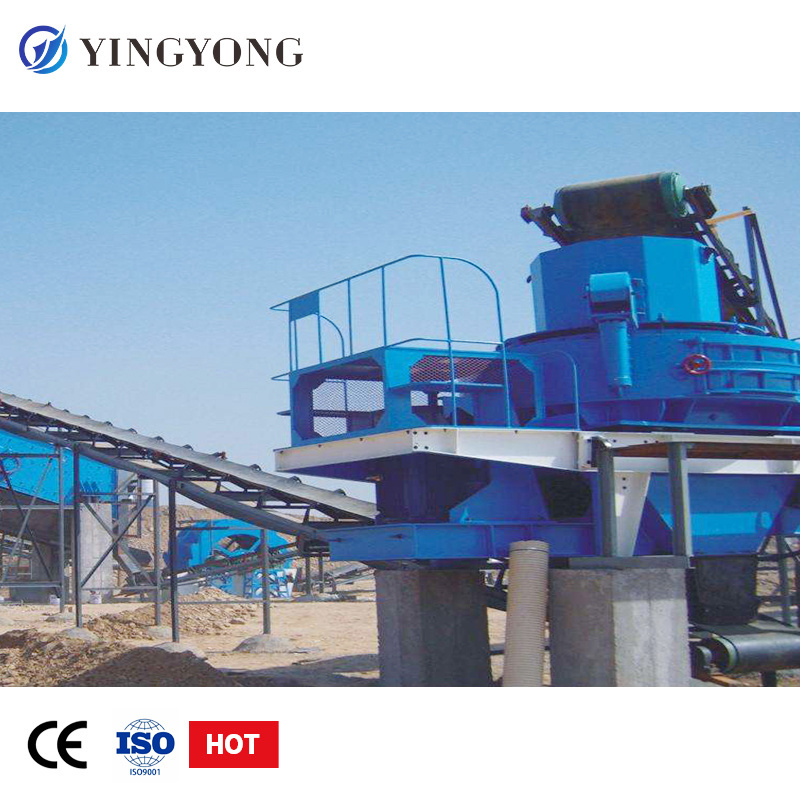

The sand making machine for sale is improved on the basis of Germany high technology, which is highly-efficient and superior in performance. The VSI Crusher (sand making machine) is widely used to produce sand and stone for highway, high-speed railway, city project, hydro power dam constructions, and concrete mixing plant, and it’s also widely used in sand making and stone reshaping industry.

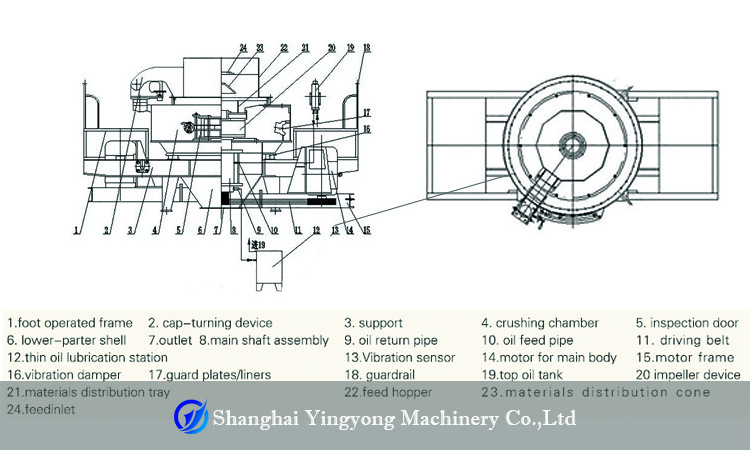

Technical parameters:

| Model | VSI-7611 | VSI-8518 | VSI-9526 | VSI-1140 | ||

| Capacity |

Center and Sides Feeding |

120-180 | 200-260 | 300-380 | 450-520 | |

| (t/h) |

Center Feeding |

60-90 | 100-130 | 150-190 | 225-260 | |

|

Max. Feeding Size (mm) |

Soft Material |

35 | 40 | 45 | 50 | |

|

Hard Material |

30 | 35 | 40 | 45 | ||

|

Rotation Speed(rpm) |

1700-1890 | 1520-1690 | 1360-1510 | 1180-1310 | ||

|

Double Motor Power (kw) |

110 | 180 | 264 | 400 | ||

| Overall Dimension | 3700×2150×2100 | 4140×2280×2425 | 4560×2447×2778 | 5000×2700×3300 | ||

| L×W×H (mm) | ||||||

| Weight (t) | 7.8 | 10.3 | 16 | 25.6 | ||

| Vibrating Sensor | Inspection Range: 0.1-20mm/s Continual Adjustment | |||||

|

Hydraulic Oil Pump |

Motor Power of Double Oil Pump(Kw) |

2×0.31kw | ||||

|

Overall Dimension |

820×520×1270 | |||||

| L×W×H (mm) | ||||||

|

Power of Oil Tank Heater |

2KW | |||||

feeding size: <50mm

capacity: 60-520t/h

application: mineral, cement, corhart, bauxite, carborundum grain, glass raw material, machine made construction sand (more application please click the "free contact")

materials: brittle materials with Mohs hardness under 9%

NO. 2 Features

1. Large quantity and high yield

50-500 t/h, and compared under the same power of traditional equipment, production increased by 30% and stability .

2. Grain shape products

Products are cube, grain shape good, reasonable gradation, adjustable fineness modulus; Especially suitable for artificial sand and stone plastic, practice has proved more than any other traditional equipment sand, cosmetic effect increased by 30%

3. Automatic detection, safe and reliable

Set vibration display and alarm device, if adverse operation can be warned, the device stop working, and achieve the purpose of protect the machine

4. Installation is simple, easy to operate

Equipment light weight, installation, portable installation; Install, repair and maintenance is simple, convenient operation and use; Once a specific purpose, VSI crusher only minor adjustments, you can maximize its excellent performance

5. Low parts consumption

The best material impact Angle of crushing cavity.problems in the design, less friction and wear parts, 30% lower than conventional equipment operation cost, reduce the use of the equipment cost directly

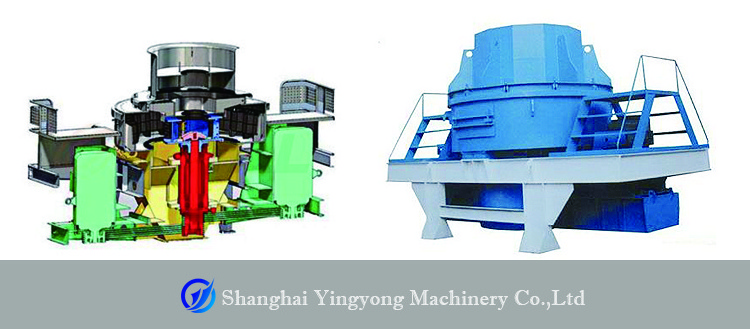

6. The hydraulic device, easy to maintain

Hydraulic open device, crushing cavity internal maintenance convenient conversion, shorten the down time, save time and effort

7. Thin oil lubrication, automatic maintenance

German original thin oil lubrication station, the double pump complementary to ensure oil supply, automatic stop when no oil, no oil pressure; Oil cooling and heating device to ensure the bearing lubrication is always in the best state. To completely solve the problem such as bearing heating, keep the spindle bearing temperature, prolong maintenance cycle and service life.

NO. 3 working principle

Stone is crushed by hitting other stones. Material falls down to impeller cavity.Under great centrifugal force, it hits material that coming downwards. After hitting each other,they force a vortex between impeller and shell, and hit each other several times, finally smaller stone comes out, and goes to vibrating screen. Satisfactory material is transported to sand washing machine, however overlarge material will go back to sand maker to be re-crushed.Output sizes can be made according to customer requirement.If input size is larger than the designed size,other crushing equipment will be necessary.

Q: Hi, are you mining machinery manufacturer?

Q: Which country have your products been exported?

A: We have been exported business for 10 years and we have lots of customers and agents in the world, such as Middle East, Malaysia, South Africa, Canada, America, etc…

Q: How long is the warranty of your equipment? Does your company supply the spare parts?

A: The usual warranty period is one year. And of course, we will supply the spare parts for you at lowest cost.

Q: If I need the complete mineral processing line, can you help us to build it?

A: Yes, we can help you combine a complete mineral processing line and give you related professional advices as long as you need. We had already build many mining projects in China & Overseas. We can set a complete processing line just as you require.

Ways of Packing:

1.Sand blasting, coat with high quality paint;

2.Product wrap by PP-Bubble

3.Load container, Spear Parts in wooden case.

Transportation:

1. By sea Freight;

2. MSK/MSC/APL/EMC/WANHAI/KLINE

3. We will remind you before boat arrival