- Product Details

- {{item.text}}

Quick Details

-

Screw diameter:

-

100/130

-

Width:

-

640-1040mm

-

Thickness:

-

1.0-3.5mm

Quick Details

-

Screw Design:

-

Single-screw

-

Place of Origin:

-

China

-

Name:

-

Extrusion Line

-

Screw diameter:

-

100/130

-

Width:

-

640-1040mm

-

Thickness:

-

1.0-3.5mm

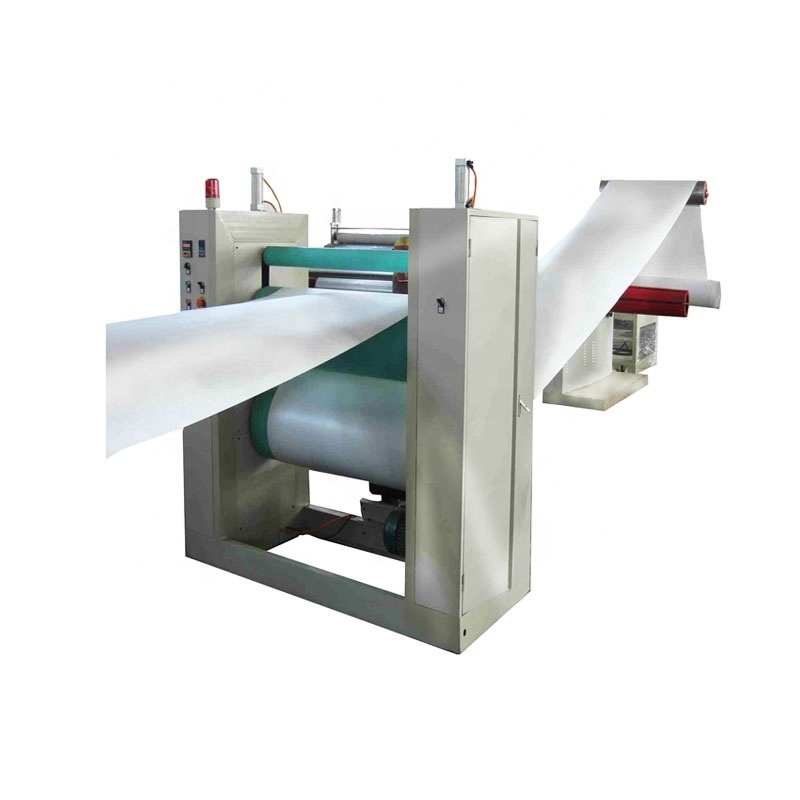

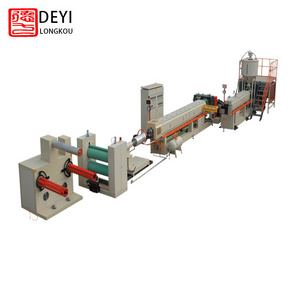

Full Automatic Factory Price PS Plastic Foam Sheet Machine For Sale

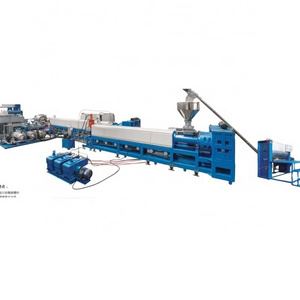

The production line adopts dual screw foam sheet extrusion technique. PSP foam sheet production is a kind of new-type packing material with the feature of heat preservation, safety, sanitation and good plasticity. It is mainly used to make various types of food containers, such as lunch boxes, dinner trays, bowls etc. by thermal forming. It is also can be used to make advertisement boards, industrial products packing and so on. It has stable performance, big capacity, high automation and high quality products.

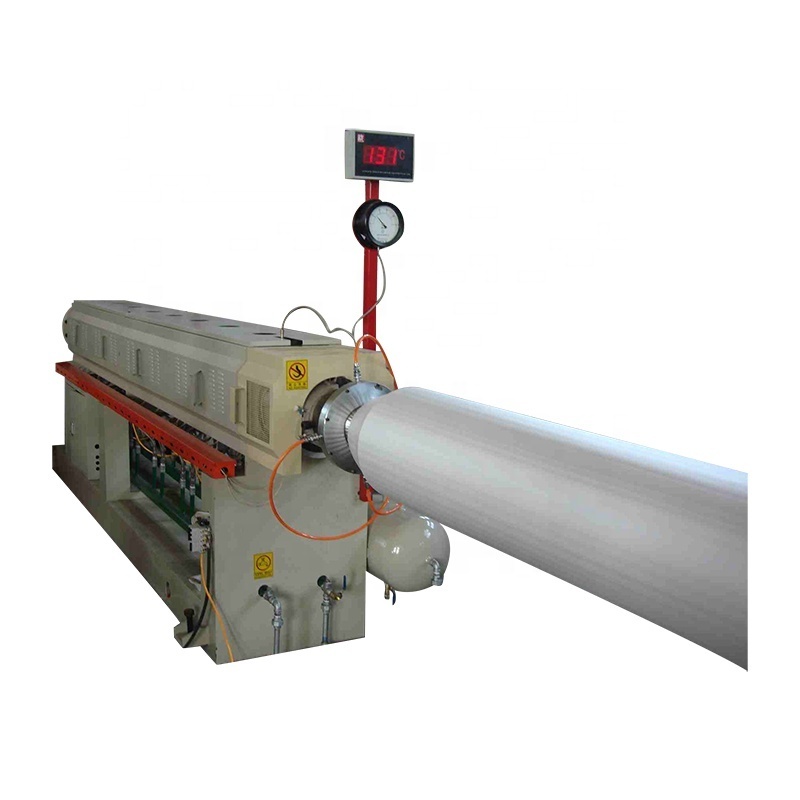

Technical flow:

General Polystyrene Granule (GPPS) with additive are mixed in feeding system, then go into

No.1 Extruder---Inject foaming agent--After filter changer, material go into N0.2 Extruder--Extruded from mold head --Cooling and Shaping--Hauling off--Winding --Finished Products—Packing.

Technical parameters:

|

Model |

Unit |

LD-PSP70/90 |

LD-PSP90/120 |

LD-PSP120/150 |

LD-PSP150/200 |

|

|

mm |

70/90 |

90/120 |

120/150 |

150/200 |

||

|

|

10-20 |

10-20 |

10-20 |

10-20 |

10-20 |

|

|

Width |

mm |

640-1040 |

640-1040 |

640-1040 |

640-1200 |

640-1350 |

|

Cutting method |

|

Single cutter |

Single cutter/double cutter |

|||

|

Thickness |

mm |

1.0-3.0 |

1.0-3.5 |

1.0-3.5 |

2.0-5.0 |

2.0-5.0 |

|

Cooling method |

|

water and wind cooling |

||||

|

Capacity |

kg/h |

50-90 |

100-180 |

230-320 |

400-600 |

|

|

Total power |

kw |

120 |

150 |

180 |

260 |

380 |

|

External size |

m |

22*4*2.8 |

24*4.1*2.8 |

28*4.2*3.2 |

28*5.2*3.2 |

|

|

Gross weight |

t |

10 |

12 |

15 |

18 |

23 |

♦ Project Design

Assist you to choose equipment, design production process flow According to the customer actual production environment and production requirements.

♦ Installation Training

Provide telephone guidance for equipment installation and debugging; or send technician to install and debug machine and train your workers if needed.

Provide free relevant training as customer required.

Long-term technical support.

♦ After-sale service

One year warranty, life-long maintenance;

24 hours online for technical consulting service;

Once Problems on equipment, provide phone or on-site troubleshooting fault response plan.

♦ One year warranty time

From the date which the product is qualified commissioning. Any damage except the wrong operation during warranty period is repaired freely. But the travel and hotel expenses should be paid by buyer.

♦ Oversea service

Engineers available to service machinery overseas.

♦ Response with 24hour

We value every inquiry sent to us, ensure quick competitive offer within 24 hour.

♦ Full document

All necessary document will be provide .

♦ Payment way

We accept multiple terms of payment, such as L/C, T/T, western Union, Money Gram, AlibabaTade Asurance.