- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

JUNYANG

-

Applicable Industries:

-

Other

-

Weight (KG):

-

1000000

-

Product name:

-

Aluminum plating film machine

-

Keywords:

-

Vacuum Coating Equipment

-

Kinds of coating:

-

Vacuum Coating

-

Advantage:

-

High Efficiency Low Cost

-

Feature:

-

Double Plating Alloy Process

-

Technology:

-

Advanced

-

Operation:

-

Operate Easily

Quick Details

-

Machine Type:

-

Electroplating Production Line

-

Marketing Type:

-

New Product 2022

-

Core Components:

-

Other

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

JUNYANG

-

Applicable Industries:

-

Other

-

Weight (KG):

-

1000000

-

Product name:

-

Aluminum plating film machine

-

Keywords:

-

Vacuum Coating Equipment

-

Kinds of coating:

-

Vacuum Coating

-

Advantage:

-

High Efficiency Low Cost

-

Feature:

-

Double Plating Alloy Process

-

Technology:

-

Advanced

-

Operation:

-

Operate Easily

Product Introduction

First-class quality comes from the first-class quality control system. Over the years, Junyang coating long-term commitment to research and development, continuous improvement and innovation of enterprise products, comprehensive domestic and foreign advanced coating technology research and development design of high vacuum coating machine with high speed, efficient, stable, reliable, cost-effective, coating speed of up to 1000 meters/min.

Single side WINDING design, improve the stability of equipment, convenient loading and unloading film, save time, improve production efficiency.

PLC control stepper motor to feed aluminum wire, accurate and reliable. Wire feeding speed and on-line measurement form a closed-loop control to ensure coating uniformity and improve product quality.

closed water circulation system is adopted, and each road is monitored by corresponding sensors.

Closed circulation can reduce the air humidity in the production workshop; At the same time effectively improve the production environment, fully meet the enterprise QS certification standards.

Closed circulation can reduce the air humidity in the production workshop; At the same time effectively improve the production environment, fully meet the enterprise QS certification standards.

advanced four-motor four-roller

drive structure, which is faster

and more stable.

Siemens high precision AC servo

Siemens high precision AC servo

motor drive, accurate and reliable control.

Efficiency comes from efficiency and quality, the machine adopts online measurement and automatic control of coating thickness and other technical measures, and the use of suspension technology, coating products without empty line, no fold, no white line, thin film thermal deformation is small, surface tension is not attenuated, reliable quality can meet the requirements of various coating materials.

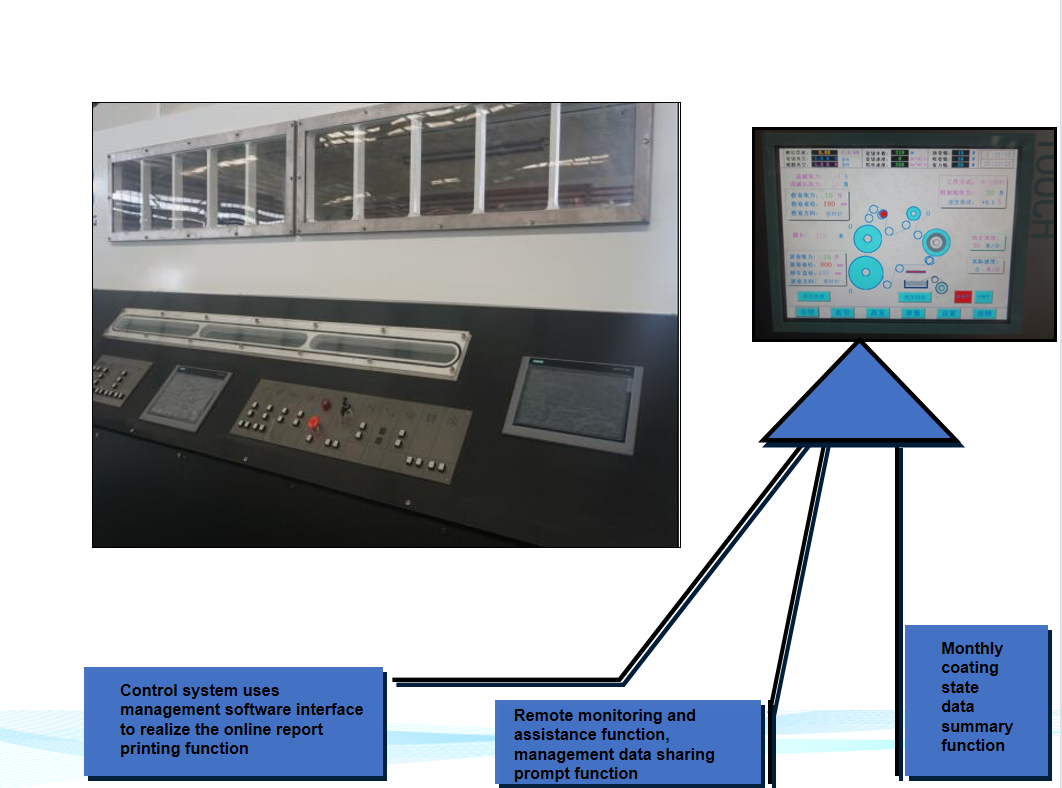

Electrical control system

The ELECTRICAL control system adopts Siemens industrial network integrated control, the transmission part adopts the latest

Siemens servo controller, equipped with Siemens AC servo motor, the control accuracy is more accurate.

The whole machine adopts PROFIBUS distributed input/output module system, and the data transmission speed is faster.

Siemens servo controller, equipped with Siemens AC servo motor, the control accuracy is more accurate.

The whole machine adopts PROFIBUS distributed input/output module system, and the data transmission speed is faster.

Vacuum system adopts high efficiency and energy saving Roots pump frequency conversion speed regulation oil-free system, large pumping speed, faster pumping speed, more energy saving, double cold trap configuration, suitable for any climate environment,vacuum time saving 50%.

Magnetically controlled optical coater

Multi-functional machining center for spare parts

High precision vertical Gantry CNC machining center

Company with integrated production and processing capacity, the product of the main parts and key parts are realized the numerical control processing, the company has advanced five-axis gantry machining center, vertical medium-sized processing center, CNC boring and milling machining center, small processing center, dozens of units, precision lathe with high precision, reliability,and the characteristics of the processing technology advanced, The standardization and modularization of product components are ensured, and the generality and stability of product components are improved.

Product rewinding and cutting

Company Introduction

Our Services & Strength

silica dielectric film coating machine, coating machine, vacuum equipment lithium battery materials.

The company is not only an equipment manufacturer, but also a coating process developer, can provide customers with a complete set of equipment, workshop. Design process and provide personnel training for customers

Hot Searches