- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu China

-

Brand Name:

-

MINGSHUN

-

Voltage:

-

according to customer

-

Dimension(L*W*H):

-

3600*1100*2100mm

-

Power (kW):

-

80

-

Weight:

-

6300 KG

-

Automatic Grade:

-

Automtic

-

Usage:

-

Production of PVC plastic pipes

-

Final product:

-

PVC pipe

-

Motor brand::

-

Siemens Beide

-

Raw material:

-

PVC Powder

-

Contactor:

-

Siemens or Schneider

-

Temperature controller:

-

RKC or OMRON

-

Main inverter brand:

-

Siemens or ABB

-

production Capacity:

-

100-800kg/h

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

132:1

-

Screw Speed (rpm):

-

70 rpm

-

Place of Origin:

-

Jiangsu China

-

Brand Name:

-

MINGSHUN

-

Voltage:

-

according to customer

-

Dimension(L*W*H):

-

3600*1100*2100mm

-

Power (kW):

-

80

-

Weight:

-

6300 KG

-

Automatic Grade:

-

Automtic

-

Usage:

-

Production of PVC plastic pipes

-

Final product:

-

PVC pipe

-

Motor brand::

-

Siemens Beide

-

Raw material:

-

PVC Powder

-

Contactor:

-

Siemens or Schneider

-

Temperature controller:

-

RKC or OMRON

-

Main inverter brand:

-

Siemens or ABB

-

production Capacity:

-

100-800kg/h

Product Description

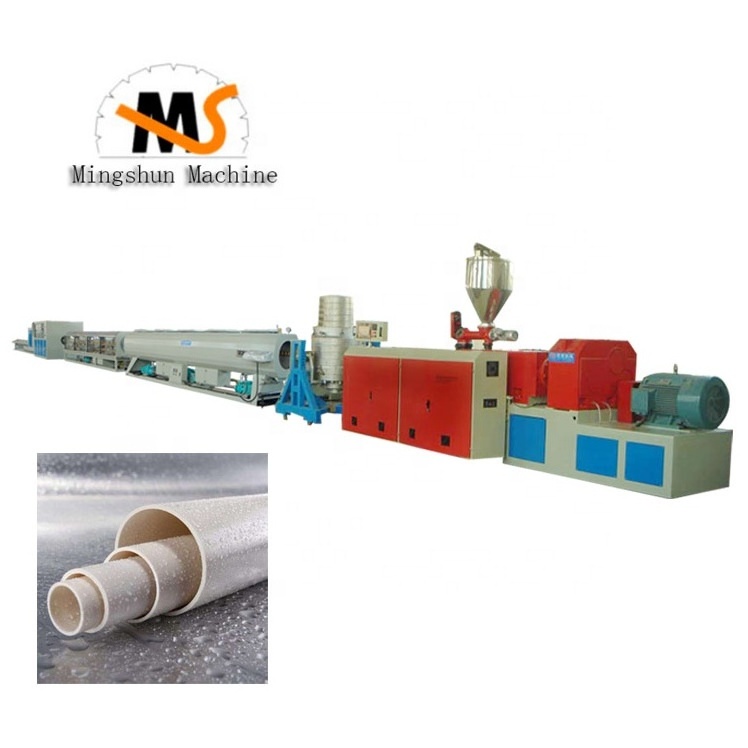

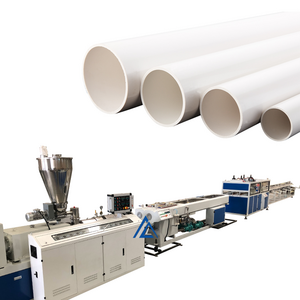

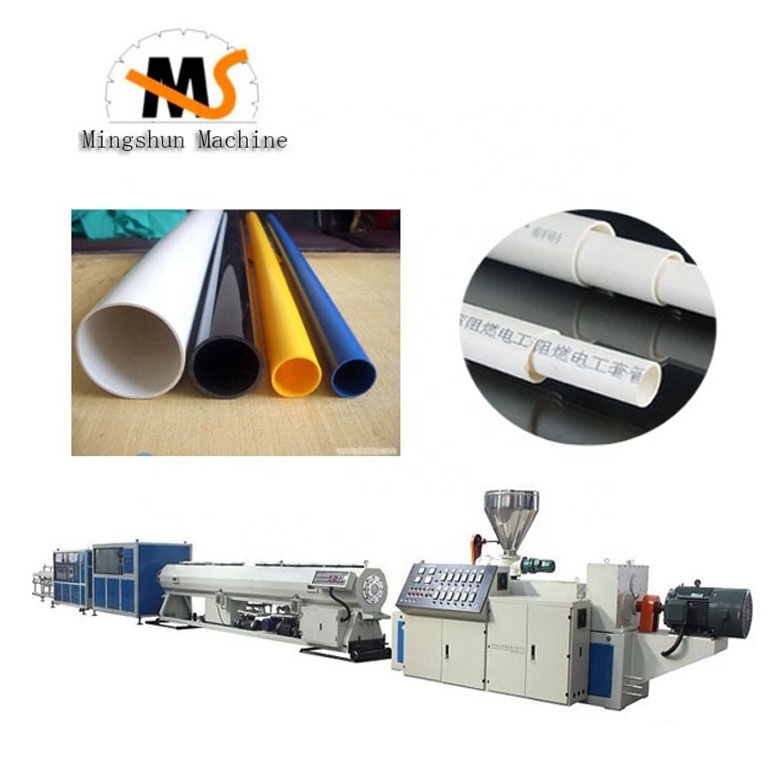

PVC pipe extrusion production line

Advantages:

The series extruders with appropriate die-mould and auxiliary machine can directly convert thermoplastic especial PVC powder into pipe,plate sheet,film and profile,and also provide function of modifying and pelleting.The extruders are derived by A.C motor with a thruster to steepless regulate.It is also equipped with the over-load protection and stoppage alarming system .The screw's core and the outside of barrel is cooled by circulation of oil,includes vacuum venting and forced feeding.

Application:

Diameter 16mm-630mm series PVC pipe extrusion production line is mainly used in the manufacture of plastic PVC pipes with various diameters and wall thickness used in the industried such as agriculture and constructional plumbing, cable laying etc.

Technical Parameters

| Model/item | Pipe range | Extruder | Max Output | Max speed | Total Power |

| PVC-50x2 | 16 | SJSZ65/132 | 250 | 10m/min | 85kw |

| PVC-63 | 16 | SJSZ51/105 | 150 | 10 | 60kw |

| PVC-110 | 50 | SJSZ55/110 | 180 | 10 | 70kw |

| PVC-160 | 63 | SJSZ65/132 | 300 | 5 | 90kw |

| PVC-250 | 110 | SJSZ65/132 | 300 | 3.5 | 120kw |

| PVC-315 | 160 | SJSZ80/156 | 400 | 3 | 160kw |

| PVC-450 | 250 | SJSZ92/188 | 700 | 1.5 | 200kw |

| PVC-630 | 315 | SJSZ92/188 | 700 | 0.9 | 230kw |

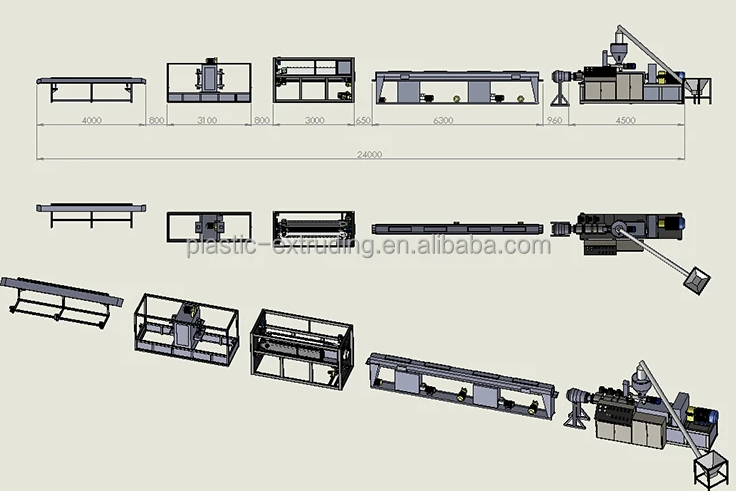

PVC pipe extrusion line flow chart:

PVC pipe line includes the following parts:

Spring feeder→Conical twin-screw extruder→mould→vacuum calibration tank→ haul off→cutter→ stake etc.

The extruder and haul off adopt imported AC frequency control device, vacuum pump and haul off motors adopt high-quality products.

The haul off methods are two-claw, three -claw, four-claw, and six-claw etc.

You may choose saw blade cutting type or planetary cutting type. It is additionlly attached with length counter and intensifying device. This line is of reliable performance and high production effeciency.

The extruder and haul off adopt imported AC frequency control device, vacuum pump and haul off motors adopt high-quality products.

The haul off methods are two-claw, three -claw, four-claw, and six-claw etc.

You may choose saw blade cutting type or planetary cutting type. It is additionlly attached with length counter and intensifying device. This line is of reliable performance and high production effeciency.

PVC one-cavity production line

This production line is mainly applicable to production

Φ16-Φ630

PVC pipes

of various wall thicknesses.It

is composed of

screw feeder, conical twin screw extruder,extrusion die, vacuum calibration tank,haul-off, motors, cutter and stacker etc.

The extruder and haul off methods are two-claw, three-claw, four-claw, six-claw, eight-claw, ten-claw, twelve claw etc. You may choose saw blade cutting type or planetary cutting type.

It is aditionaly attached with length counter and intensifying device. This line with reliable performance and high production eficiency. Our company can also manufacture special pipe production lines,e.g. spiral silencing pipe and core foaming pipe according to your requirements.

PVC two-cavity production line

The production line is developed with the advanced technology of west Europe which is brought by separate-control double tube extruding by our company. This line is mainly applicable to double-cavity which has Φ16-40mm or Φ16-63mm . The main machine is SJSZ55/110 or SJSZ65/132 conical twin screw extruder is equipped with double-tubesingle control stainless steel spraying calibration,it avoids waste condition when one tube is adjusted and the other one is affected. The auto single-control double drawing machine and cuting machine arecombined with the front double calibration technology to make operation more flexible let you enjoy economic benefit.

The production line is developed with the advanced technology of west Europe which is brought by separate-control double tube extruding by our company. This line is mainly applicable to double-cavity which has Φ16-40mm or Φ16-63mm . The main machine is SJSZ55/110 or SJSZ65/132 conical twin screw extruder is equipped with double-tubesingle control stainless steel spraying calibration,it avoids waste condition when one tube is adjusted and the other one is affected. The auto single-control double drawing machine and cuting machine arecombined with the front double calibration technology to make operation more flexible let you enjoy economic benefit.

PVC four-cavity production line

Four cavities PVC electrical tube,water supply pipeextrusion line can extruder four pipes at same time onone machine.This line can save investment cost in factory buiding and production,which increase the capacity a lot and reduce production time.SJSZ65/132 conical twin-screw extruder can easily reach 5.5-6.5 ton/per day,the production speed take 16mm as example can get more than 8-10m/min.The whole line is composed of conical twin-screw extruder 65/132,4 cavity mould,4 cavity coling 4 calibration tank,4 station haul off,4 station cutter and 4 station tipping table.

Four cavities PVC electrical tube,water supply pipeextrusion line can extruder four pipes at same time onone machine.This line can save investment cost in factory buiding and production,which increase the capacity a lot and reduce production time.SJSZ65/132 conical twin-screw extruder can easily reach 5.5-6.5 ton/per day,the production speed take 16mm as example can get more than 8-10m/min.The whole line is composed of conical twin-screw extruder 65/132,4 cavity mould,4 cavity coling 4 calibration tank,4 station haul off,4 station cutter and 4 station tipping table.

Related products

Hot Searches