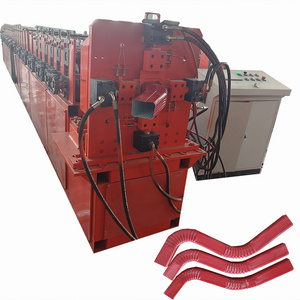

Manual Uncoiler --- Entry Beach --- Roll Forming Machine --- Automatic Shearing Mechanism --- Computer Control Cabinet --- Run-out Tables

- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

XINBO

-

Voltage:

-

380V 50HZ or at buyer's request

-

Dimension(L*W*H):

-

20*2.2*1.8 meters

-

Weight:

-

4000 kg

-

Marketing Type:

-

New Product 2022

-

Processing Material:

-

PPGI,GI,Aluminium

-

Input Width(mm):

-

914mm/1000mm/1200mm/1250mm As customer's needing

-

Formed Width(mm):

-

914mm/1000mm/1200mm/1250mm As customer's needing

-

Processing Thickness(mm):

-

0.28--0.8

-

Material of Rollers:

-

Material of Rollers

-

Diameter of Shaft:

-

70mm

-

Production Speed:

-

12---15m/min

-

Roller Driven:

-

Decelerating Motor+Chain Transmission

-

Cutting Model:

-

Hydraulic Profile Cutting

-

Operation Model:

-

Button + Touch Screen

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

20M/MIN

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

XINBO

-

Voltage:

-

380V 50HZ or at buyer's request

-

Dimension(L*W*H):

-

20*2.2*1.8 meters

-

Weight:

-

4000 kg

-

Marketing Type:

-

New Product 2022

-

Processing Material:

-

PPGI,GI,Aluminium

-

Input Width(mm):

-

914mm/1000mm/1200mm/1250mm As customer's needing

-

Formed Width(mm):

-

914mm/1000mm/1200mm/1250mm As customer's needing

-

Processing Thickness(mm):

-

0.28--0.8

-

Material of Rollers:

-

Material of Rollers

-

Diameter of Shaft:

-

70mm

-

Production Speed:

-

12---15m/min

-

Roller Driven:

-

Decelerating Motor+Chain Transmission

-

Cutting Model:

-

Hydraulic Profile Cutting

-

Operation Model:

-

Button + Touch Screen

Product Description

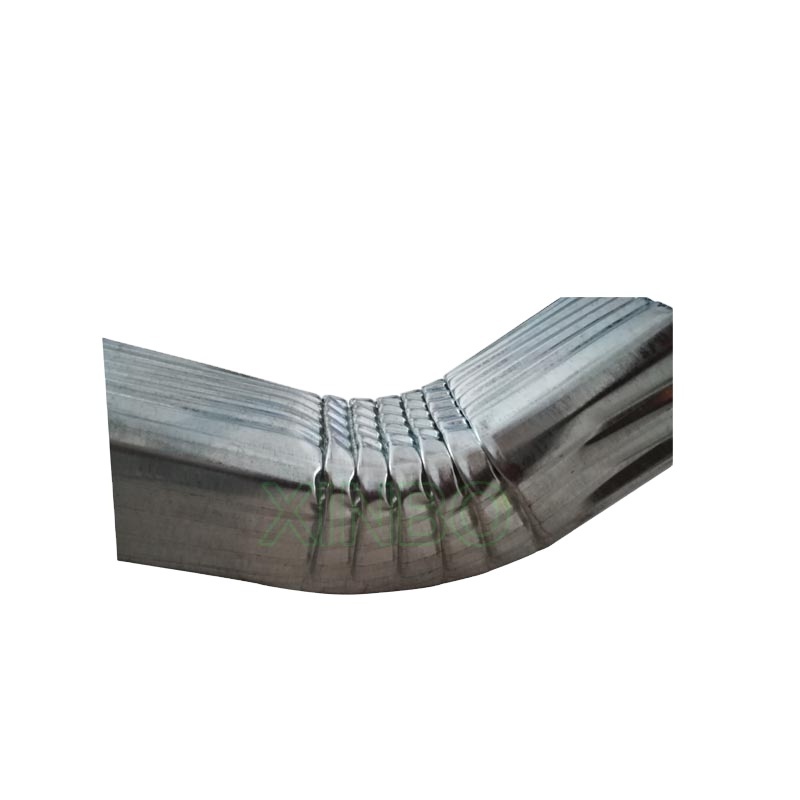

The Panels made by our Roll Forming Machine have beautiful appearance and bright color. They are widely used in gardens, factories, resorts, hotels, exhibition halls, vacationlands, ancient architectures and modern villas.

Processing flowchart

Detailed Images

It is used to support the steel coil and uncoil it in a turnable way. The steel coil is uncoiled by hand.

Loading capacity:

1-2

T

Inner diameter:

450-508mm

Computer Control Cabinet

automatic and manual one. The system is easy to operate and use.

Material of blades:

Cr12

Components:

It contains one set of cutting tools, one hydraulic tank and one cutter machine.

Entry Beach

Put the raw material(steel plate) through the beach to manufacture and process, it can guarantee that the products are neat, parallel and everything is uniformity. Please refer

to the equipment regulation to know the function of locate angle iron.

to the equipment regulation to know the function of locate angle iron.

Hydraulic Station

It is controlled by gear wheel oil pump. After filling the hydraulic oil into the hydraulic oil tank ,the pump drive the cutter

machine to begin the cutting job.

Power of The Pump: 4kw

Hydraulic oil : 40#

machine to begin the cutting job.

Power of The Pump: 4kw

Hydraulic oil : 40#

Components:

The system includes a set of hydraulic tank , a set of hydraulic oil pump, two hydraulic pipes.and two sets of

electromagnetism valves.

electromagnetism valves.

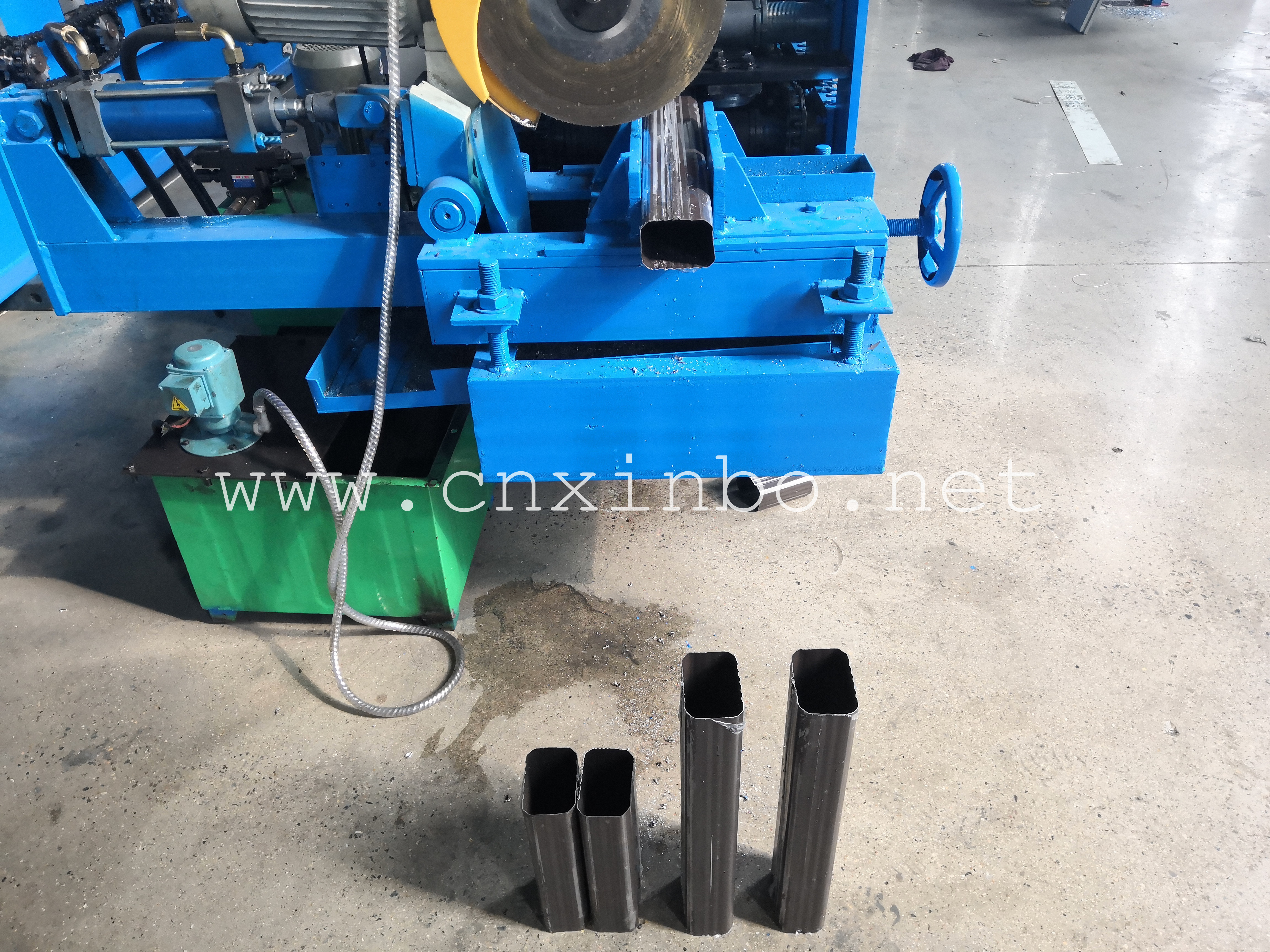

Forming Machine

In order to keep the product shape and precision, adopts welded sheet structure, motor reducer drive, chain transmission, roller

surfaces polishing, hard plating , heat treatment and galvanizational treatment . The polished surface and the heat treatment

towards the molds also can keep the molding plate surface smooth and not easy to be marked when it is being stamped.

surfaces polishing, hard plating , heat treatment and galvanizational treatment . The polished surface and the heat treatment

towards the molds also can keep the molding plate surface smooth and not easy to be marked when it is being stamped.

Main power:

4kw(cycloidal planetary gear speed reducer)

Material of rollers: 45# steel, surface hard chromium plating.

Material of rollers: 45# steel, surface hard chromium plating.

Products Receiving Tables

Packing&Shipping

Bare covered,with water proof cloth and stow-wood.Imported computer control system packed with water proof cloth and cardboard.

After Sales Service

machine for free;if it is used at abroad,we will send the professional technician to debug.

Company Introduction

Botou Xinbo Import & Export Co.,Ltd mainly produce and sell All kinds of machines and cnc machining services, roll forming machines, C Z purlin machine, deck floor machines, stud &track light keel machine, T grid machine, downpipe machine, EPS and Rockwool sandwich panel machines for the building structure and all kinds of CNC machining services.

FAQ

1. What is your guarantee period?

Guaranteed against malfunctions due to manufacturing defects for 12 months from the date of loading.

2. Do you provide training for my workers?

The machine has been installed and tested well before shipping. It is easy to operate. Normally speaking, our customer follows the instruction book and can operate the machine well. You can also come to our factory to check the machine and learn how to operate before shipping. It only needs 2 hours and you can operate well.

3. What is included in the machine?

The process for work: decoiler→feeding→roll forming→measuring length→cutting to length→product to stand

The whole line includes a manual decoiler, roll forming machine and product stand. when you get the machine in your factory, you just need to do following 3 things, and then you can start working.

a. Put the machine on the flat level ground.

b. Inject gear oil and hydraulic oil.

c. Connect 3 phase electric wire.

Guaranteed against malfunctions due to manufacturing defects for 12 months from the date of loading.

2. Do you provide training for my workers?

The machine has been installed and tested well before shipping. It is easy to operate. Normally speaking, our customer follows the instruction book and can operate the machine well. You can also come to our factory to check the machine and learn how to operate before shipping. It only needs 2 hours and you can operate well.

3. What is included in the machine?

The process for work: decoiler→feeding→roll forming→measuring length→cutting to length→product to stand

The whole line includes a manual decoiler, roll forming machine and product stand. when you get the machine in your factory, you just need to do following 3 things, and then you can start working.

a. Put the machine on the flat level ground.

b. Inject gear oil and hydraulic oil.

c. Connect 3 phase electric wire.

Hot Searches