- Product Details

- {{item.text}}

Quick Details

-

Power:

-

132KW

-

Dimension(L*W*H):

-

3000*1950*2200MM

-

Weight (KG):

-

5900

-

Capacity(t/h):

-

4-5T/H

-

Number of the Hammer(Slice):

-

96

-

Name:

-

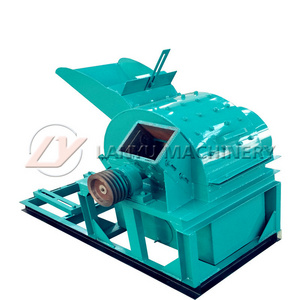

high effective hammer mill

-

Application:

-

Crush Wood Chips Making Sawdust

-

Raw material:

-

Wood Materials

-

Final product:

-

3-5mm Sawdust

-

Advantage:

-

Easy Operation High Efficiency

-

After Warranty Service:

-

Online Support Video Technical Support

-

Certification:

-

CE ISO

-

Related machine:

-

Biomass Pellet Machine

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

TONY

-

Voltage:

-

380V

-

Power:

-

132KW

-

Dimension(L*W*H):

-

3000*1950*2200MM

-

Weight (KG):

-

5900

-

Capacity(t/h):

-

4-5T/H

-

Number of the Hammer(Slice):

-

96

-

Name:

-

high effective hammer mill

-

Application:

-

Crush Wood Chips Making Sawdust

-

Raw material:

-

Wood Materials

-

Final product:

-

3-5mm Sawdust

-

Advantage:

-

Easy Operation High Efficiency

-

After Warranty Service:

-

Online Support Video Technical Support

-

Certification:

-

CE ISO

-

Related machine:

-

Biomass Pellet Machine

Product Description

Brief Introduction for High Effective Hammer Mill

TFD series high-efficiency hammer mill is a grinding machine specially used for raw materials crushing in the biomass fuel production process. It has two series of single spindle and dual spindle, with features of high output and efficiency. It can crush wood chips, shavings, crop and plant crude fibers, roughage, etc.

The Details of High Effective Hammer Mill

Advantages for High Effective Hammer Mill

2). The motor and crusher are direct-connected driving with drum coupling and built-in rotors. Dead-zone free crushing and better uniform granularity.

3).The magnetic selector on the upper part can sort out the magnetic metal materials and reduce the machine’s damage rate.

4).Forged hammers has symmetric homogeneous permutation, small vibration without blind angle, large crushing friction area.Wear-resisting material behind sieving slice has big wrapping angle. Hammer are independent designed with fasteners for easy assembly. The blades are enhanced for better wear-resistance and longer working life.

5).After balance calibration, rotors can work reversely.

6).The operating door has safety interlock equipment to make sure it can not be opened when the machine is running.

7).The blower’s efficiency is maximized with faster pneumatic conveying and minimum wind resistance. Arc side door ensures easy observation and replacement of the sieve, without disturbing wind and flying dust.

Technical Parameters:

Product Presentation

High effective hammer mill is the most ideal grinding equipment for all kinds of wood chips, wood shavings, grass, straw, stalk,rice husk, palm fiber and so on. When crush plastic, PVC, rubber etc. It adopts water cooling structure inside, avoiding the damage to spare parts due to long time working friction. Except biomass, it also can crush animal feed materials such as soybean,maize, cereal and fertilizer materials from animal manure, chemical etc. Which is mainly used in wood factory, feed factory,organic fertilizer factory, and so on.

Certificate

Related Products

Company Introduction

Packing&Shipping

FAQ

Hot Searches