- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

MONA

-

Model Number:

-

MN

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

3600*1200*1700mm

-

Weight:

-

800 KG

-

Type:

-

SPECIAL Non Woven Bag Making Machine

-

Product name:

-

Woven Bag Sewing Machine|Sacks Bags Sewing Machine price

-

Function:

-

T-shir Bag Making

-

Feature:

-

Advanced Technology

-

Application:

-

Rice Bag

-

Speed:

-

40-200pcs/min

-

Total power:

-

5kw

-

Product:

-

Hot Cutting Edge Sealing Bag Making Machine

-

Model:

-

MNFQ500

-

Usage:

-

Pp Woven Mesh Bag

Quick Details

-

Machine Type:

-

Bag Forming Machine

-

Bag Type:

-

Soft Loop Handle Bag

-

Material:

-

Non Woven Bag

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

MONA

-

Model Number:

-

MN

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

3600*1200*1700mm

-

Weight:

-

800 KG

-

Type:

-

SPECIAL Non Woven Bag Making Machine

-

Product name:

-

Woven Bag Sewing Machine|Sacks Bags Sewing Machine price

-

Function:

-

T-shir Bag Making

-

Feature:

-

Advanced Technology

-

Application:

-

Rice Bag

-

Speed:

-

40-200pcs/min

-

Total power:

-

5kw

-

Product:

-

Hot Cutting Edge Sealing Bag Making Machine

-

Model:

-

MNFQ500

-

Usage:

-

Pp Woven Mesh Bag

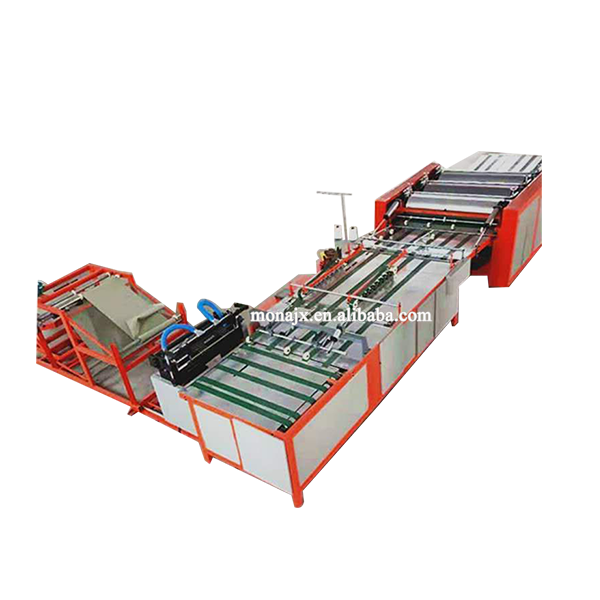

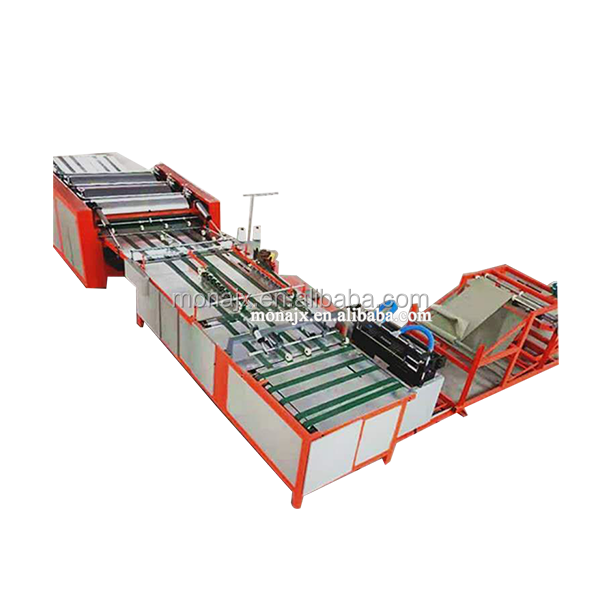

3 colors automatic pp woven poly sack carry bags manufacturing cutter printer making production line bags making machine price

3 colors automatic pp woven poly sack carry bags manufacturing cutter printer making production line bags making machine price

Introduction of Non-Woven Bag Making Machine:

This product uses the unique technology, according to the woven bag cutting, the seam production process, according to today's labor cost rise, the production process of the original backward, professional design of one-stop automatic professional equipment, the product standard, neat. The production procedure achieves the humanized service completely. It can completely replace the previous heavy manual labor. The working procedure is divided into winding - cutting - holding - sewing - bagging.

Application of cutting and stitching sewing sealing machine:

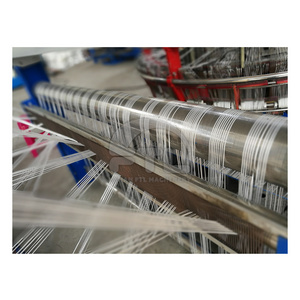

This woven bag cutting & sewing & printing machine is mainly used to cut the half finished tubular woven fabric roll into sheets and then sew and print it to get finished bags. The machine also can collect the finished bags together to save labor cost.

The materials include

Plastic bags: PP (polypropylene) bags, PE ( polythene) bags, HDPE bags, Plastic film bags, Single-sided film covering bags, double-sided film-covered bags, etc.

Kraft paper bags;

Paper-plastic composite bags , etc.

For example:

Chemical woven bags : cement bags, putty powder woven bags, sand bags, fertilizer bags, urea woven bags,etc.

Feed Woven bags : poultry feed bags, fish feed bags, etc.

Food packaging bags : rice woven bags, flour woven bags, salt bags, corn woven bags, grains bags, seeds bags, etc.

Tourism transportation industry : logistics bags, logistics packaging bags, shipping bags, shipping bags, etc.

Anti-flooding materials : anti-information woven bags, drought-resistant woven bags, flood-proof woven bags.

Characteristics of Non-woven bag cutting and sewing machine:

1.This machine is designed to make rolling and dotting vest bags and flat bags.

2.comptuer control and adopts step or servo setting length system to reduces the length setting errors.

3.the photocell eyes track help make the position of printed bags accurately.

4.the computer control can be selected to set the bag length accurately.

5.the machine will automatically stop and warn operator if there is something wrong in improperly operation.

M ain technical parameter of Non-woven bag cutting and sewing machine:

|

Model |

MNFQ500 |

MNFQ600 |

MNFQ800 |

|

Width of bag making(mm) |

400mm |

500mm |

700mm |

|

Length of bag making (mm) |

1200mm |

1200mm |

1200mm |

|

Thickness og bag making |

0.008-015 |

0.008-0.15 |

0.008-0.15 |

|

speed of bag making |

40-200pcs/min |

40-200pcs/min |

40-200pcs/min |

|

motor power |

1.1kw |

1.1kw |

1.5kw |

|

electric heating power |

1.2kw |

1.6kw |

2.2kw |

|

weight |

800kg |

900kg |

1000kg |

|

dimension(L*W*H)MM |

3600*1200*1700 |

3600*1300*1700 |

3600*1500*1700 |