- Product Details

- {{item.text}}

Quick Details

-

Ejector Stroke(mm):

-

160 mm

-

Ejector Force(kN):

-

77 kN

-

Theoretical Shot Volume(cm³):

-

749.3 cm³

-

Injection Rate (g/s):

-

205.5 g/s

-

Injection Weight (g):

-

689.3 g

-

Screw Speed (rpm):

-

1 - 161 rpm

-

Screw diameter (mm):

-

60 mm

-

Screw L/D Ratio:

-

20

-

Distance between Tie Bars:

-

570x570 mm

-

Weight (KG):

-

8000 kg

-

Place of Origin:

-

Guangdong, China

-

Open Stroke(mm):

-

530 mm

-

Model Number:

-

UN260SKII

-

Brand Name:

-

YIZUMI

-

Power (kW):

-

40.6 kW

-

Injection pressure:

-

169.4Mpa

-

Marketing Type:

-

Hot Product 2019

Quick Details

-

Distance between Tie Bars(Width)(mm):

-

570mm

-

Distance between Tie Bars(Height)(mm):

-

570mm

-

Mold Height(mm):

-

195 - 610 mm

-

Ejector Stroke(mm):

-

160 mm

-

Ejector Force(kN):

-

77 kN

-

Theoretical Shot Volume(cm³):

-

749.3 cm³

-

Injection Rate (g/s):

-

205.5 g/s

-

Injection Weight (g):

-

689.3 g

-

Screw Speed (rpm):

-

1 - 161 rpm

-

Screw diameter (mm):

-

60 mm

-

Screw L/D Ratio:

-

20

-

Distance between Tie Bars:

-

570x570 mm

-

Weight (KG):

-

8000 kg

-

Place of Origin:

-

Guangdong, China

-

Open Stroke(mm):

-

530 mm

-

Model Number:

-

UN260SKII

-

Brand Name:

-

YIZUMI

-

Power (kW):

-

40.6 kW

-

Injection pressure:

-

169.4Mpa

-

Marketing Type:

-

Hot Product 2019

Product Description

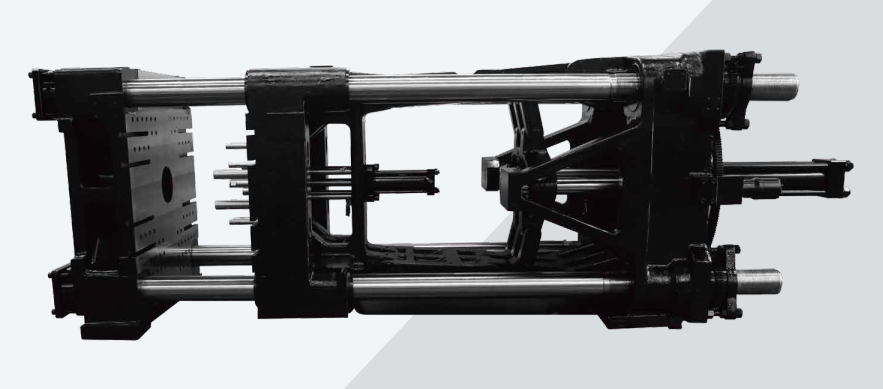

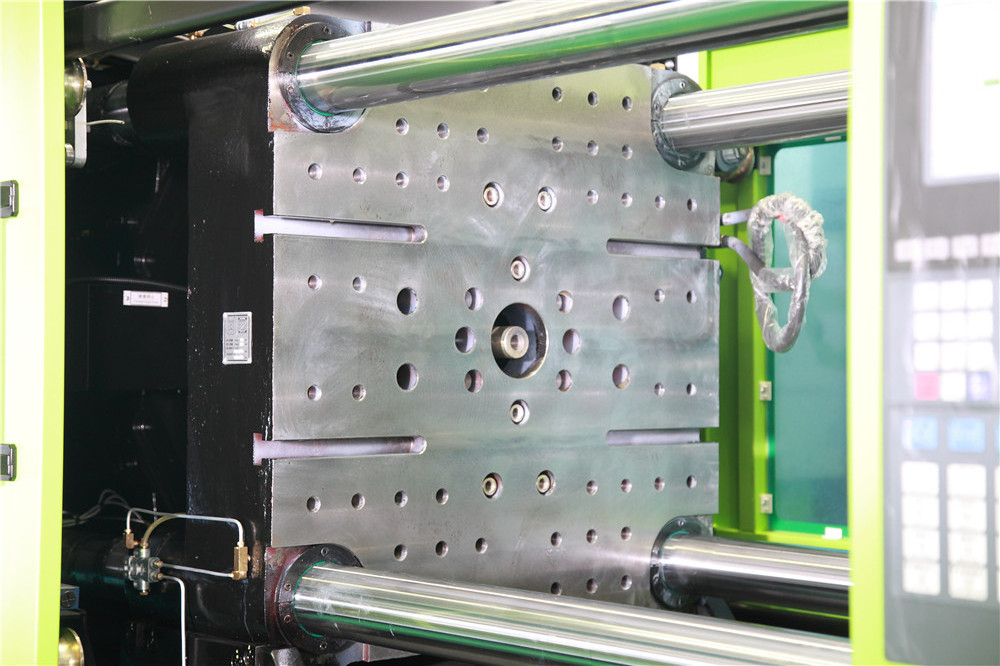

CLAMPING UNIT

Combination with T-Slot & bolt holes

The platen has both T slots and bolt holes in horizontal direction, but only bolt holes in vertical direction. Such layout makes the setup and removal of mold easier and increases the overall rigidity of platen.

Adjustment-free mechanical safety lock

The adjustment-free safety lock is located at the tail platen for automatic mechanical protection.

User-friendly

INJECTION UNIT

Optimized injection unit

UN260SKII-480SKII machines adopt integrated injection carriage frame design. The optimized design of injection mechanism increases the rigidity, ensures the coaxiality of forces on motion and injection, reduces resistance and improves the stability and accuracy of injection.

Optimized screw design

The plasticizing efficiency and quality are enhanced to meet customer needs for fast plasticization, good color mixing and easy cleaning

Movable hopper guide rails(standard

feature for 90T-320T)

Centralized lubrication module

Purge guard and barrel cover

User-friendly design

Standard features, including movable hopper guide rails, barrel cover, purge guard and centralized lubrication add to the

convenience of operation and maintenance and raises the overall efficiency for customers.

convenience of operation and maintenance and raises the overall efficiency for customers.

Hydraulic system

The third-generation servo

1.low energy consumption, strong power and fast response

2.Overall hydraulic circuit optimization reduces flow loss.

3.The resistance to moving parts, including the clamping unit and injection unit is further reduced, raising the response speed and reducing frictional loss.

Optimized oil cooler design

UN90-320SKII machines are equipped with built-in diaphragm type oil cooler and they have good look, compact structure and higher cooling efficiency.

Control system

MH9118 controller: fast speed, accurate control, easy operation, program for multiple processes, powerful

1.

MH9118 controller which runs fast and clock rate up to 140MHZ

2

. 8"TFT 256-color LCD with independent CPU control

3

. Machine control frequency of 140MHZ, scanning time of 1ms, fast response and accurate control

4.

100 sets of molding data storage with USB port

5.

Production quality control with main process parameter statistics

6

. Automatic tuning of PID settings for barrel temperature control

Specification

|

|

DESCRIPTION

|

UNIT

|

DATA

|

|

Injection unit

|

Shot volume

|

cm3

|

749.3

|

|

|

Shot weight (PS)

|

g

|

689.3

|

|

|

|

oz

|

24.3

|

|

|

Screw diameter

|

mm

|

60

|

|

|

Injection pressure

|

Mpa

|

169.4

|

|

|

Injection rate

|

g/s

|

205.5

|

|

|

Screw L:D ratio

|

|

20:1

|

|

|

Max. injection speed

|

mm/s

|

79

|

|

|

Screw stroke

|

mm

|

265

|

|

|

Screw speed(stepless)

|

r/min

|

0-161

|

|

Clamping unit

|

Clamping force

|

kN

|

2600

|

|

|

Opening stroke

|

mm

|

530

|

|

|

Space between bars

|

mm*mm

|

570x570

|

|

|

Max. Daylight

|

mm

|

1140

|

|

|

mold thickness(Min.Max)

|

mm

|

195-610

|

|

|

Hydraulic ejection storke

|

mm

|

160

|

|

|

Ejector number

|

|

13

|

|

|

Hydraulic ejection force

|

kN

|

77

|

|

Power unit

|

Hydraulic system pressure

|

Mpa

|

17.5

|

|

|

Pump motor

|

kw

|

24

|

|

|

Heating capacity

|

kw

|

16.6

|

|

|

Number of temp control zones

|

|

5

|

|

General

|

Dry cycle time

|

s

|

3.1

|

|

|

Oil tank capacity

|

L

|

335

|

|

|

Machine dimensions(LxWxH)

|

m*m*m

|

6.24x1.59x1.96

|

|

|

Machine weight

|

kg

|

8000

|

NOTE:

The listed machine price is for standard machine only, any extra requirement (e.g. CE/UL/KCS safety standard and so on) will be subject to extra charge.

Packing & Delivery

Hot Searches