- Product Details

- {{item.text}}

Quick Details

-

Max. Spindle Speed (r.p.m):

-

1000 r.p.m

-

Max. Weight of Workpiece(kg):

-

2000

-

Spindle Bore(mm):

-

200

-

Width of bed (mm):

-

400 mm

-

Spindle Motor Power(kW):

-

30

-

Max. Turned Length (mm):

-

800

-

Travel (X Axis)(mm):

-

670 mm

-

Travel (Z Axis)(mm):

-

900 mm

-

Place of Origin:

-

Shandong, China

-

Dimension(L*W*H):

-

2480x2200x3350mm

-

Brand Name:

-

DEHAI YAOYANG

-

Model Number:

-

VTC80

-

Voltage:

-

380V

-

Weight (KG):

-

10000

-

CNC or Not:

-

CNC

-

Machine Type:

-

Vertical Lathe

-

Product name:

-

CNC Vertical Turning Lathe

-

Name:

-

CNC Vertical Lathe

-

Keyword:

-

Cnc Metal Lathe Machine

-

Function:

-

Machining Metal

-

Model:

-

VTC80

-

Precision:

-

High Precision Machine

-

Automatic Grade:

-

Automatic CNC Turning Machine

-

Control system:

-

SIEMENS GSK FANUC (optional)

Quick Details

-

Type:

-

VERTICAL

-

Max. Length of Workpiece (mm):

-

800mm

-

Year:

-

2023

-

Max. Spindle Speed (r.p.m):

-

1000 r.p.m

-

Max. Weight of Workpiece(kg):

-

2000

-

Spindle Bore(mm):

-

200

-

Width of bed (mm):

-

400 mm

-

Spindle Motor Power(kW):

-

30

-

Max. Turned Length (mm):

-

800

-

Travel (X Axis)(mm):

-

670 mm

-

Travel (Z Axis)(mm):

-

900 mm

-

Place of Origin:

-

Shandong, China

-

Dimension(L*W*H):

-

2480x2200x3350mm

-

Brand Name:

-

DEHAI YAOYANG

-

Model Number:

-

VTC80

-

Voltage:

-

380V

-

Weight (KG):

-

10000

-

CNC or Not:

-

CNC

-

Machine Type:

-

Vertical Lathe

-

Product name:

-

CNC Vertical Turning Lathe

-

Name:

-

CNC Vertical Lathe

-

Keyword:

-

Cnc Metal Lathe Machine

-

Function:

-

Machining Metal

-

Model:

-

VTC80

-

Precision:

-

High Precision Machine

-

Automatic Grade:

-

Automatic CNC Turning Machine

-

Control system:

-

SIEMENS GSK FANUC (optional)

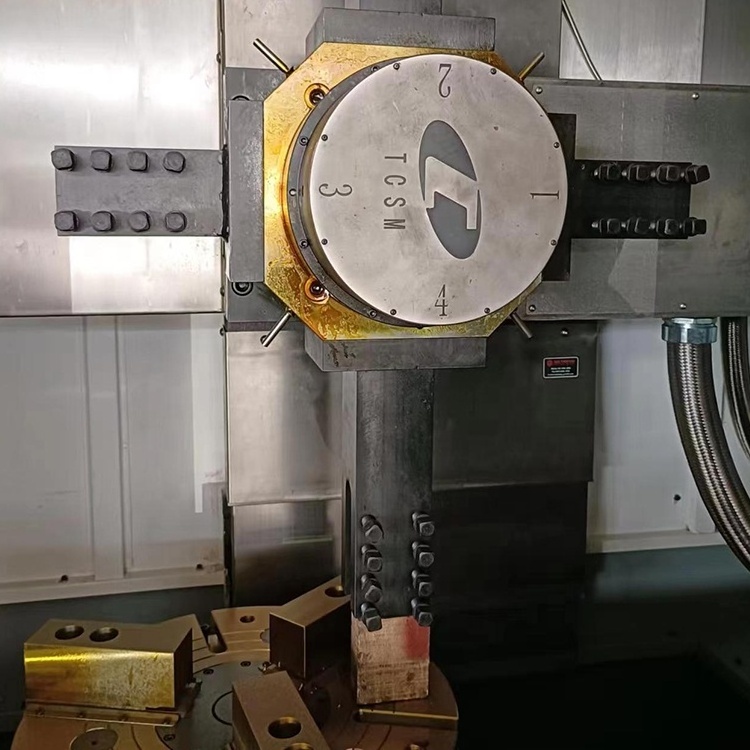

VTC series CNC vertical lathe

VTC series CNC vertical lathe adopts Taiwan famous brand roller type linear slide rail. With super high rigidity and super heavy load capacity. The positioning accuracy and carrying capacity of the vertical and horizontal feed motion of the machine tool have been greatly improved.

The pulley of the main shaft of the machine tool and the pulley of the CNC servo motor of the spindle are linked by a belt, equipped with a high-torque servo motor, stepless speed change, and a wide speed range. Meet the different requirements of the rough machining and finishing machining of the parts on the spindle speed.

The tool holder of the machine tool adopts horizontal or vertical multi-station CNC tool holder, which shortens the tool change time and greatly improves the work efficiency. The live tool turret can be selected according to customer needs to realize the functions of milling, drilling and tapping.

The upper end of the spindle can be equipped with a disc-type worktable or a hydraulic chuck according to customer requirements. The lower end of the spindle is equipped with a single-piston cylinder or a double-piston cylinder, which is used to control the pressing of the workpiece and the hydraulic chuck.

Product Paramenters

|

ITEM

|

|

VTC50

|

VTC60

|

VTC70

|

|

|

Travel

|

x-axis

|

500mm

|

450mm

|

700mm

|

|

|

|

z-axis

|

500mm

|

650mm

|

700mm

|

|

|

Capacity

|

Max.swing dia.

|

Φ650mm

|

Φ650mm

|

Φ780mm

|

|

|

|

Max.turning dia.

|

Φ500mm

|

Φ600mm

|

Φ700mm

|

|

|

Spindlr

|

Spindle speed

|

80~1000rpm

|

100~1000rpm

|

100~800rpm

|

|

|

|

Spindle motor power

|

15kw

|

18.5Kw

|

22kW

|

|

|

|

Dimension-Outside

|

130mm

|

160mm

|

60mm

|

|

|

Chuck & automatic tool changer

|

Chuck type

|

Hydraulic chuck

|

Hydraulic chuck

|

Hydraulic chuck

|

|

|

|

Dia.Chuck

|

Φ400

|

Φ500

|

Φ630

|

|

|

|

Work Station

|

Horizontal 8 station

|

Horizontal 8 station

|

Horizontal 8 station

|

|

|

Slide way

|

x-axis slide way

|

2 pcs, 45mm wide

|

2 pcs, 45mm wide

|

2 pcs, 45mm wide

|

|

|

|

z-axis slide way

|

2 pcs, 45mm wide

|

2 pcs, 55mm wide

|

2 pcs, 55mm wide

|

|

|

Ball screw

|

Ball screw accuracy

|

P3

|

C3

|

C3

|

|

|

|

Ball screw diameter x.y.z

|

x:Φ40mm

|

x:Φ40

|

x:Φ40

|

|

|

|

|

z:Φ40mm

|

z:Φ50

|

z:Φ50

|

|

|

|

Lead

|

10mm

|

10mm

|

10mm

|

|

|

Control system

|

Spindle motor

|

15kw

|

18.5kw

|

22kw

|

|

|

|

X zaxis motor

|

10NM

|

18NM

|

15NM

|

|

|

|

Z zaxis motor

|

22NM

|

30NM

|

15NM

|

|

|

Accuracy

|

Repeat positioning

|

±0.005mm

|

0.008mm

|

0.008mm

|

|

|

|

Positioning

|

±0.01mm

|

0.008mm

|

0.01mm

|

|

|

|

Least input increment

|

0.001mm

|

0.001mm

|

0.001mm

|

|

|

Power require

|

Power source

|

3¢-AC 380V 50Hz±5%

|

3¢-AC 380V 50Hz±10%

|

3¢-AC 380V 50Hz±5%

|

|

|

Others

|

Cross weight

|

5000kg

|

6500kg

|

8000kg

|

|

|

|

Packing dimensions

|

2100*2500*2750mm

|

2000*1950*3000mm

|

2200*2000*3250mm

|

|

|

ITEM

|

|

VTC80

|

VTC100

|

|

|

Travel

|

x-axis

|

670mm

|

870mm

|

|

|

|

z-axis

|

900mm

|

900mm

|

|

|

Capacity

|

Max.swing dia.

|

Φ1000mm

|

Φ1200mm

|

|

|

|

Max.turning dia.

|

Φ800mm

|

Φ1000mm

|

|

|

Spindlr

|

Spindle speed

|

100~1000rpm

|

100~800rpm

|

|

|

|

Spindle motor power

|

22Kw

|

22Kw

|

|

|

|

Dimension-Outside

|

180mm

|

200mm

|

|

|

Chuck & automatic tool changer

|

Chuck type

|

Hydraulic chuck

|

Hydraulic chuck

|

|

|

|

Dia.Chuck

|

Φ630

|

Φ800

|

|

|

|

Work Station

|

Horizontal 8 station

|

Horizontal 8 station

|

|

|

Slide way

|

x-axis slide way

|

2 pcs, 45mm wide

|

2 pcs, 55mm wide

|

|

|

|

z-axis slide way

|

2 pcs, 55mm wide

|

2 pcs, 55mm wide

|

|

|

Ball screw

|

Ball screw accuracy

|

C3

|

C3

|

|

|

|

Ball screw diameter x.y.z

|

x:Φ40

|

x:Φ50

|

|

|

|

|

z:Φ50

|

z:Φ50

|

|

|

|

Lead

|

10mm

|

10mm

|

|

|

Control system

|

Spindle motor

|

22kw

|

22kw

|

|

|

|

X zaxis motor

|

18NM

|

18NM

|

|

|

|

Z zaxis motor

|

30NM

|

30NM

|

|

|

Accuracy

|

Repeat positioning

|

0.008mm

|

0.007mm

|

|

|

|

Positioning

|

0.008mm

|

±0.01mm

|

|

|

|

Least input increment

|

0.001mm

|

0.001mm

|

|

|

Power require

|

Power source

|

3¢-AC 380V 50Hz±5%

|

3¢-AC 380V 50Hz±5%

|

|

|

Others

|

Cross weight

|

10500kg

|

11000kg

|

|

|

|

Packing dimensions

|

2480*2200*3350mm

|

2600*2300*3450mm

|

|

Details Images

Product packaging

Manufacturing Technique

FAQ

1. What is your MOQ and warranty?

A: The minimum order quantity is one set, the warranty period is one year, and lifetime technical support is provided.

2. What is the delivery time?

A: The production period of the machine is generally about 30 working days.

3. What is the packaging of the machine?

A: The standard packaging of the machine is an iron pallet and a plastic film wooden box.

4. How to choose the most suitable machine?

A: Please let us know your processing needs or machine parameters, we can choose the best model for you, or you can choose the exact model yourself. You can also send us product drawings and our engineers will make reasonable recommendations.

5. What are your trade terms?

A: FOB, CFR, CIF or other terms are all acceptable.

6. What are the payment terms?

A: T/T, 30% down payment when ordering, 70% balance before shipment.

7.Are you a manufacturer or trader?

A: We are a manufacturer, we have more than 5 engineers to provide you with technical support, we do not sell machines that we do not produce.

Hot Searches