- Product Details

- {{item.text}}

Quick Details

-

Diameter:

-

105-127mm

-

Available Shank Type:

-

DHD, Mission, SD, QL, COP Series Bit

-

Application:

-

Mining, Well Drilling, Construction

-

Bit Face:

-

Flat/Convex/Concave Face

-

Advantage:

-

High Quality and Direct Manufacturer

-

Carbide Inserts Shape:

-

Hemispherical/Parabolic/Ballistic Button

-

Packing:

-

Wooden Box

-

Experience in Rock Tools Industry:

-

Over 30 Years

-

Net Weight:

-

5.5-10 kg

Quick Details

-

Place of Origin:

-

Guizhou, China

-

Brand Name:

-

Neutral

-

Product name:

-

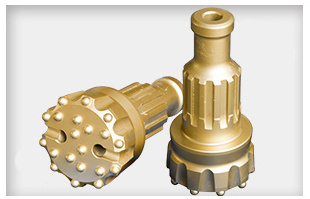

High Air Pressure Mining DTH Drill Bits

-

Diameter:

-

105-127mm

-

Available Shank Type:

-

DHD, Mission, SD, QL, COP Series Bit

-

Application:

-

Mining, Well Drilling, Construction

-

Bit Face:

-

Flat/Convex/Concave Face

-

Advantage:

-

High Quality and Direct Manufacturer

-

Carbide Inserts Shape:

-

Hemispherical/Parabolic/Ballistic Button

-

Packing:

-

Wooden Box

-

Experience in Rock Tools Industry:

-

Over 30 Years

-

Net Weight:

-

5.5-10 kg

DTH Hammer Deep Rock Well BoreHole Drilling Bit Mining Button Drill Bits

DTH Button Bit s: Acedrills is in the position to offer a comprehensive range of DTH drill bits with all diameters of the current prevailing manufacturers’ hammer shank designs to match various drilling applications. All our DTH drill bits are also CAD designed, CNC manufactured for perfect bits body, and multiple heat-treated to enhance hardness, surface-compressed for fatigue resistance, all thus to extend the product life for maximum wear and performance in the toughest of drilling conditions. Moreover, all these bits are also made from high quality alloy steels and fitted with premium quality tungsten carbide tips for superior penetration rate.

|

|

Hammer Size |

|

2 ” ~3.5 ” |

|

|

4 ” ~8 ” |

|

|

10 ” ~32 ” |

|

|

Hammer Shank Style |

|

|

BR, AHD, Cop, Mission... |

|

|

Mincon, Numa, QL, TD... |

|

|

SD, DHD, XL, ACD, Mach... |

|

|

|

Face Design Flat, Concave, Convex |

PRODUCT SPECIFICATION

Medium and High Pressure Hammer Bits :

| Hammer Size | Hammer Shank Style | Bit Diameter | Face Design | Insert Shapes | |

| mm | inch | ||||

| 2 | BR1 | 64~76 | 2 1/2 ~ 3 | FF, CV | S, P, B, C |

| 2.5 | BR2, Minroc 2, AHD25 | 76~90 | 3 ~ 3 1/2 | FF, CV | S, P, B, C |

| 3.5 | BR 3, Minroc 3, Mach33/303, DHD3.5, TD35, XL3, Mission 30, COP32, Secoroc3, COP34 | 85~105 | 3 3/8 ~ 4 1/8 | FF, CV | S, P, B, C |

| 4 | DHD340A/DHD4, COP44, Secoroc4/44, Numa4, Mincon 4, SD4(A34-15), QL40, Mission 40, COP42, Mach 40/44, Dominator 400, XL4 | 105~130 | 4 1/8 ~ 5 | FF, CV, CC | S, P, B, C |

| 5 | DHD350R, COP54, Secoroc5/54, Mach 50, SD5(A43-15), BR5V, COP54 Gold, QL50, TD50/55, HP50/55, Patriot 50, Mission 50/55, COP52, XL5/5.5 | 137~165 | 5 3/8 ~ 6 1/2 | FF, CV, CC | S, P, B, C |

| 6 | DHD360, DHD6/6.5, SF6, COP64, Secoroc 6, Challenger/Patriot 6, XL61/PD61, Mach 60, COP64 Gold, QL60, SD6(A53-15)/PD6, ADEC-6M, TD60/65/70, HP60/HP65, Mission 60/60W/65, COP62, XL6 | 152~203 | 6 ~ 8 | FF, CV, CC | S, P, B, C |

| 8 | DHD380, COP84, Secoroc 84, Mach 80, Challenger/Patriot 80, SD8(63-15), XL8, QL80, Mission 80/85 | 203~305 | 8 ~ 12 | FF, CV, CC | S, P, B |

| 10 | SD10, Numa100 | 241~356 | 9 1/2 ~ 14 | FF, CC | S |

| 12 | DHD112, XL12, Mach132, Mach120, SD12(A100-15), NUMA120, NUMA125 | 305~419 | 12 ~ 16 1/2 | FF, CC | S |

| 14 | ACD145 | 381~470 | 15 ~ 18 1/2 | FF, CC | S |

| 18 | ACD185 | 445~660 | 17 1/2 ~ 26 | FF, CC | S |

| 20 | ACD205 | 495~711 | 19 1/2 ~ 28 | FF, CC | S |

| 24 | ACD245 | 711~990 | 28 ~ 39 | FF, CC | S |

| 32 | ACD325 | 720~1118 | 28 1/2 ~ 44 | FF, CC | S |

Specification Notice

How to order? Shank Type + Diameter + Face Design + Button Configuration

For brochure and more product information , please click here to t ell us the detail .

|

To Chose the Right Products

When selecting the right bit for optimum performance you have to balance penetration against bit life . On occasion you can successfully sacrifice b it life for penetration, remember the rule of thumb that states that a 10% increase in penetration covers at least a 20% loss in bit life. Acedrills commonly has three basic bits head designs: Flat Face, Convex and Concave. These are designed for specific applications for all rock types, hardness’s and conditions: