- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

±0.5%

-

Voltage:

-

220V 50-60HZ

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Sunswell

-

Weight:

-

9500 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Filling bottle volume:

-

500ml,750ml, 3L etc

-

carbonated beverage filling machine::

-

rinser,filler,capper

-

Processing Type:

-

Draft Beer

-

Power(W):

-

9.2KW

-

Marketing Type:

-

Hot Product 2021

Quick Details

-

Machinery Capacity:

-

Other, 12000BPH, 6000BPH, 20000BPH, 16000BPH

-

Packaging Material:

-

Plastic, Metal, Glass

-

Filling Material:

-

Beer, Other, Water, Juice

-

Filling Accuracy:

-

±0.5%

-

Voltage:

-

220V 50-60HZ

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Sunswell

-

Weight:

-

9500 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Filling bottle volume:

-

500ml,750ml, 3L etc

-

carbonated beverage filling machine::

-

rinser,filler,capper

-

Processing Type:

-

Draft Beer

-

Power(W):

-

9.2KW

-

Marketing Type:

-

Hot Product 2021

Descriptions and Specifications of Equipment

1 Carbonation Mixer

1 Carbonation Mixer

General Introduction

QHS series beverage mixer has the reasonable structure, high precision mix, plenty CO2 mix. Mainly applies to all carbonated

beverages mixed processing, and can also be used for other beverages. It is the main equipment in complete equipments of

carbonated beverage manufacturing.

Main features

1) Advanced mass flow in-line blending and carbonation for reduced product & ingredient losses;

2) High efficiency deaeration

3) Simplified, user-friendly, operator interface

4) Automated “ no-dump” start-up capability

5) Complete product recipe management

6) Ingredient usage trending and totalling

7) Improved product yields and consistency

8) Reduced B.O.D. cost

9) Fast, favorable return-on-investment

Process

Water De-aeration Water Carbonation Proportioning of water and syrup Cooling System

2 Depalletizer

QHS series beverage mixer has the reasonable structure, high precision mix, plenty CO2 mix. Mainly applies to all carbonated

beverages mixed processing, and can also be used for other beverages. It is the main equipment in complete equipments of

carbonated beverage manufacturing.

Main features

1) Advanced mass flow in-line blending and carbonation for reduced product & ingredient losses;

2) High efficiency deaeration

3) Simplified, user-friendly, operator interface

4) Automated “ no-dump” start-up capability

5) Complete product recipe management

6) Ingredient usage trending and totalling

7) Improved product yields and consistency

8) Reduced B.O.D. cost

9) Fast, favorable return-on-investment

Process

Water De-aeration Water Carbonation Proportioning of water and syrup Cooling System

2 Depalletizer

DESCRIPTION

This equipment has a scientific process flow, reliable performance, high degree of automation, simple operation and high cost

performance. It is an ideal packaging equipment for various companies and is welcomed by the food and beverage industry and the

chemical industry.

MAIN STRUCTURAL FEATURES AND COMPOSITION

a. Mechanical structure is simple, solid, less land occupation, low maintenance, long service life;

b. The whole machine is controlled by imported PLC, with multiple safety protection, reliable operation and full automatic

operation;

c. Suitable for various stacking and bottle types, convenient adjustment and high production efficiency;

d. With touch-screen control, friendly interface and easy operation;

e. Using high quality conveyor chain segmented transmission, the access section can be lengthened arbitrarily

f. Motor, cylinder drive and control are all imported famous brand components

g. Try to use 304 materials, which meet the hygienic standard, the machine is beautiful and generous.

TECHNICAL PARAMETERS

This equipment has a scientific process flow, reliable performance, high degree of automation, simple operation and high cost

performance. It is an ideal packaging equipment for various companies and is welcomed by the food and beverage industry and the

chemical industry.

MAIN STRUCTURAL FEATURES AND COMPOSITION

a. Mechanical structure is simple, solid, less land occupation, low maintenance, long service life;

b. The whole machine is controlled by imported PLC, with multiple safety protection, reliable operation and full automatic

operation;

c. Suitable for various stacking and bottle types, convenient adjustment and high production efficiency;

d. With touch-screen control, friendly interface and easy operation;

e. Using high quality conveyor chain segmented transmission, the access section can be lengthened arbitrarily

f. Motor, cylinder drive and control are all imported famous brand components

g. Try to use 304 materials, which meet the hygienic standard, the machine is beautiful and generous.

TECHNICAL PARAMETERS

|

Model

|

XD200

|

|

Production capacity

|

12000 cans/hour

|

|

Applicable bottle

|

cans

|

|

Compressed air consumption

|

0.01M3 /min , 6~8bar

|

|

Operating voltage(AC)

|

380V

|

|

Control voltage(DC)

|

24V

|

|

Total power

|

6.37KW

|

|

Total weight

|

5000kg

|

3 Can Rinser

General description

It is used to clean empty can in canning production line. Empty cans will be sent to turning device first, which will be turned

around then transferred into rinsing machine. Empty can will be running from top to bottom along the turning device. When empty

cans enter into rinser, they will be cleaned by 80ºC hot water (provided by customer) to reach aseptic state of can. There is

certain inclination angle in both sides of rinser, whose size could be adjusted properly when needed. Empty cans will be rolling

in parallel way from top to end; the waste water will be discharged from outfall.

Technical parameters

It is used to clean empty can in canning production line. Empty cans will be sent to turning device first, which will be turned

around then transferred into rinsing machine. Empty can will be running from top to bottom along the turning device. When empty

cans enter into rinser, they will be cleaned by 80ºC hot water (provided by customer) to reach aseptic state of can. There is

certain inclination angle in both sides of rinser, whose size could be adjusted properly when needed. Empty cans will be rolling

in parallel way from top to end; the waste water will be discharged from outfall.

Technical parameters

|

Required capacity

|

0-200 CPM (330ml)

|

|

Diameter of Can

|

53~66mm

|

|

Height of Can

|

70~175mm

|

|

Dimensions

|

6200×470×310mm (L×W×H)

|

|

Machine weight

|

500Kg

|

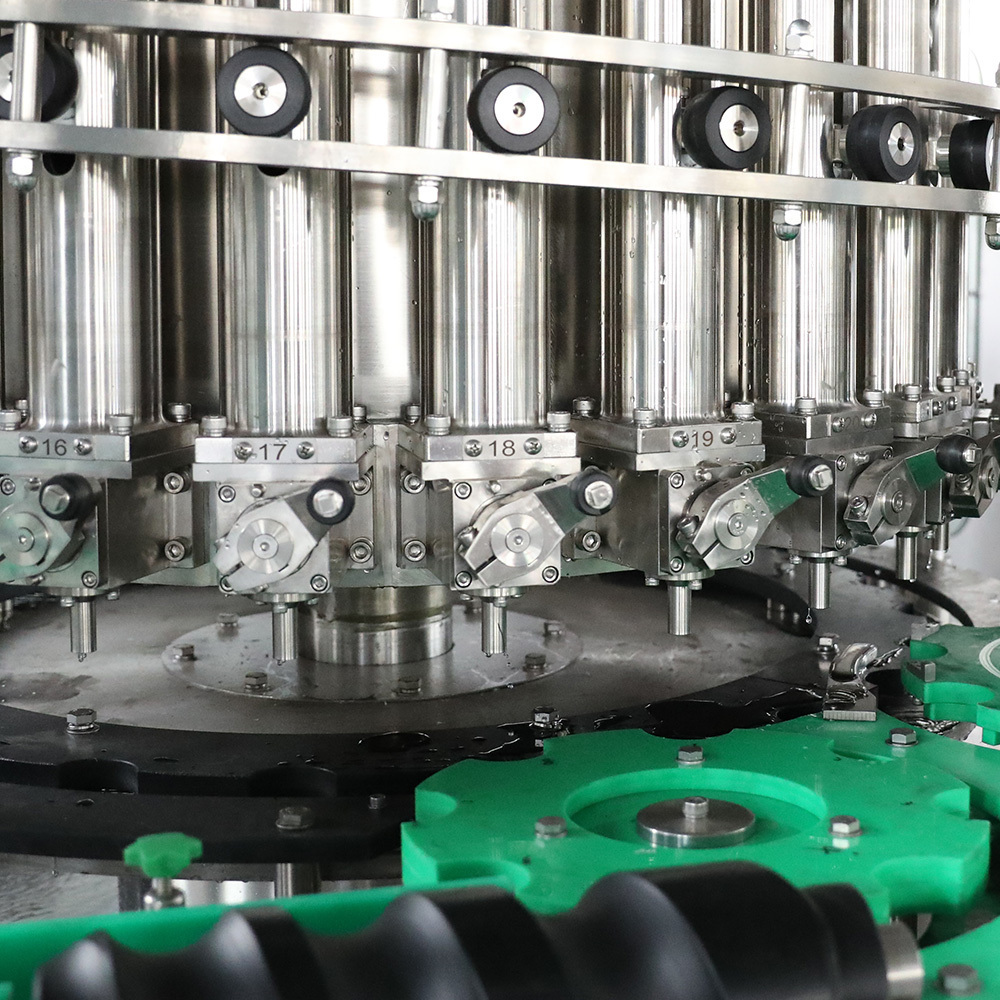

4 Can Filler/Seamer Monoblock

Description

It is suitable for filling and seaming carbonated liquid such as cola, beer, functional beverage, etc. It is equipped the advanced

device, electrical equipment, and pneumatic control technology. It has the characteristics of filling reposefully, high speed,

liquid level control, seaming reliably, frequency conversion timing, less material loss. It is the preferred equipment for

beverage plants.

Features

Wholly sealed widow structure which is beautiful, concise, easy and highly operated;

Product tank design with precision polishing inside;

High precision and large flow rate filling valves to meet productive requirement;

Specially designed roller structure which is easy to be adjusted, locked and ensure sealing function;

Friendly and convenient operating panel with high expansibility.

Working Procedure

Cans will be pushed into can holding platform one by one by feeding screw and star-wheel. Centering cup of filling valve will fall

to can; the distance between filling valves and cans is sealed by springiness plastic ring. The movement of centering cup is

generated by plastic idler wheel along curvilinear motion. After filled, valve will be closed and centering cup will rise from the

can. Filled can will be sent to conveyor chain, then to seamer. Seamer will take lid, turn over the edge of can and turn the edge

to finish the sealing action by the control of cam. After that can will be transferred to conveying system.

5 X-ray Level Detector

It is suitable for filling and seaming carbonated liquid such as cola, beer, functional beverage, etc. It is equipped the advanced

device, electrical equipment, and pneumatic control technology. It has the characteristics of filling reposefully, high speed,

liquid level control, seaming reliably, frequency conversion timing, less material loss. It is the preferred equipment for

beverage plants.

Features

Wholly sealed widow structure which is beautiful, concise, easy and highly operated;

Product tank design with precision polishing inside;

High precision and large flow rate filling valves to meet productive requirement;

Specially designed roller structure which is easy to be adjusted, locked and ensure sealing function;

Friendly and convenient operating panel with high expansibility.

Working Procedure

Cans will be pushed into can holding platform one by one by feeding screw and star-wheel. Centering cup of filling valve will fall

to can; the distance between filling valves and cans is sealed by springiness plastic ring. The movement of centering cup is

generated by plastic idler wheel along curvilinear motion. After filled, valve will be closed and centering cup will rise from the

can. Filled can will be sent to conveyor chain, then to seamer. Seamer will take lid, turn over the edge of can and turn the edge

to finish the sealing action by the control of cam. After that can will be transferred to conveying system.

5 X-ray Level Detector

Description

Filling level detector is developed to meet international advanced level liquid level detection requirements. Use of low-energy

X-ray after the interaction with the tested substances, materials-ray intensity with the test material surface changes the

position of principle, to control the detection of liquid filling material capacity. Because of its non-contact measurement, a

fundamental solution to the conventional weighing method cannot measure the liquid filling material on the production line

capacity problems. It is widely used in food, pharmaceutical, chemical and other filling (either bottled or canned) liquid-line

automatic control of the pipeline material. For ensuring product quality, increase economic efficiency and social significance.

Features

l Non-contact detection, speed and accuracy. Whether bottled, canned and other production lines could be detected on the surface

of the filling.

l In line with a variable speed transmission state, free from transmission with rate stability limit.

l Stainless steel housing, sealed design and manufacture of the host, steam fog, water droplets, and environmental adaptability.

l Relative measurement method using free samples, free from temperature measurement resolution, long-term drift effects.

l Single-chip computer, the instrument anti-interference ability, high reliability.

l Sound, light alarm, and automatically remove the containers failed.

l Instrument set up inspection procedures and debugger, with the ability to automatically check for faults.

l Big touch screen display, LED backlit LCD, writing clear, bright, man-machine dialogue operation.

l Contain radioactive isotopes, radiation protection safe and reliable.

6 Air Blow Dryer

Filling level detector is developed to meet international advanced level liquid level detection requirements. Use of low-energy

X-ray after the interaction with the tested substances, materials-ray intensity with the test material surface changes the

position of principle, to control the detection of liquid filling material capacity. Because of its non-contact measurement, a

fundamental solution to the conventional weighing method cannot measure the liquid filling material on the production line

capacity problems. It is widely used in food, pharmaceutical, chemical and other filling (either bottled or canned) liquid-line

automatic control of the pipeline material. For ensuring product quality, increase economic efficiency and social significance.

Features

l Non-contact detection, speed and accuracy. Whether bottled, canned and other production lines could be detected on the surface

of the filling.

l In line with a variable speed transmission state, free from transmission with rate stability limit.

l Stainless steel housing, sealed design and manufacture of the host, steam fog, water droplets, and environmental adaptability.

l Relative measurement method using free samples, free from temperature measurement resolution, long-term drift effects.

l Single-chip computer, the instrument anti-interference ability, high reliability.

l Sound, light alarm, and automatically remove the containers failed.

l Instrument set up inspection procedures and debugger, with the ability to automatically check for faults.

l Big touch screen display, LED backlit LCD, writing clear, bright, man-machine dialogue operation.

l Contain radioactive isotopes, radiation protection safe and reliable.

6 Air Blow Dryer

General description

The fast-blowing air from the blow of the high-pressure fan is sprayed out of an aperture, to remove the remaining waters from

bottles to a high extent. The aperture is side-positioned to blow all sides of bottles with fast flowing air

Equipment makeup

l High-pressure fan

l Pressure equalizer box

l Air pipe

l Machine frame

l Control part

7 Date printer

The fast-blowing air from the blow of the high-pressure fan is sprayed out of an aperture, to remove the remaining waters from

bottles to a high extent. The aperture is side-positioned to blow all sides of bottles with fast flowing air

Equipment makeup

l High-pressure fan

l Pressure equalizer box

l Air pipe

l Machine frame

l Control part

7 Date printer

Print features

• Mono-jet printhead

• G head (printing resolution: 71 dpi)

• Up to 4 lines of print

• Print speed: up to 4.4 m/s

• Font height from 5 to 24 dots

• Character height: from 1.8 to 8.7 mm

• Wide choice of characters (Latin, Arabic, Cyrillic, Greek, Japanese, Chinese, Hebrew, Korean…)

Other characteristics

• Weight: 18.5 kg

• 2-metre flexible umbilical cable

• Stainless steel cabinet

•Dust/humidity protection rating: IP55

• No plant air required

• Operating temperature range: 0° to 40° C, depending on ink used

• Humidity: 10% to 90% non-condensing

• Electrical power supply: 100 - 120 V or 200 - 240 V with automatic switching; frequency 50/60 Hz; power 34 W

Operations

• Message library (up to 100 messages)

•International operator/machine interface (choice of 31 languages)

• Large WYSIWYG backlit blue screen

• Integrated help for navigation and diagnostics

• Creation of logos directly on the operator/machine interface

• USB port

• M6’ ink circuit

• Jet Speed Control guarantees marking quality

• Automatic selection of fonts, depending on print speed and printhead/object distance

• Possibility to choose ink types: quick-drying MEK-free and MEK , alcohol-based, Colour changing for Sterilisation process

• 2 sealed intelligent cartridges, 0.8 litre each

• Quick connect/disconnect of accessories (photocell, encoder, alarm)

• RS-232 connectivity

Photos: Ginko

Printed in France on recycled paper - A48142 E1

Options

• One and two-dimensional barcodes (Datamatrix)

• Ethernet connectivity

• Printhead pressurisation kit (plant air required)

• Autonomous pressurisation kit (no plant air required)

• 3-metre umbilical

Accessories

• Printer supports: stands (stainless steel or aluminum), table or wall mounting bracket

• Stainless steel printhead cover

• Photocell

• Encoder

• Alarm beacon (24 V)

• Conveyor stop output

8 Automatic PE Film Shrink Wrapper

• Mono-jet printhead

• G head (printing resolution: 71 dpi)

• Up to 4 lines of print

• Print speed: up to 4.4 m/s

• Font height from 5 to 24 dots

• Character height: from 1.8 to 8.7 mm

• Wide choice of characters (Latin, Arabic, Cyrillic, Greek, Japanese, Chinese, Hebrew, Korean…)

Other characteristics

• Weight: 18.5 kg

• 2-metre flexible umbilical cable

• Stainless steel cabinet

•Dust/humidity protection rating: IP55

• No plant air required

• Operating temperature range: 0° to 40° C, depending on ink used

• Humidity: 10% to 90% non-condensing

• Electrical power supply: 100 - 120 V or 200 - 240 V with automatic switching; frequency 50/60 Hz; power 34 W

Operations

• Message library (up to 100 messages)

•International operator/machine interface (choice of 31 languages)

• Large WYSIWYG backlit blue screen

• Integrated help for navigation and diagnostics

• Creation of logos directly on the operator/machine interface

• USB port

• M6’ ink circuit

• Jet Speed Control guarantees marking quality

• Automatic selection of fonts, depending on print speed and printhead/object distance

• Possibility to choose ink types: quick-drying MEK-free and MEK , alcohol-based, Colour changing for Sterilisation process

• 2 sealed intelligent cartridges, 0.8 litre each

• Quick connect/disconnect of accessories (photocell, encoder, alarm)

• RS-232 connectivity

Photos: Ginko

Printed in France on recycled paper - A48142 E1

Options

• One and two-dimensional barcodes (Datamatrix)

• Ethernet connectivity

• Printhead pressurisation kit (plant air required)

• Autonomous pressurisation kit (no plant air required)

• 3-metre umbilical

Accessories

• Printer supports: stands (stainless steel or aluminum), table or wall mounting bracket

• Stainless steel printhead cover

• Photocell

• Encoder

• Alarm beacon (24 V)

• Conveyor stop output

8 Automatic PE Film Shrink Wrapper

MB series machine has been designed for no tray, no cardboard case, packing with low cost in the operations, it is widely used in

food, beverage, chemical and office industries

Technical Specification

Packing form: bottles and cans

Packing speed: 10 packs/min

Applicable container shape: circular container, quadrate container

Total power charge: 19kw three-phase-five-line 380v/50Hz

Machine size: L×W×H=6500×3200×2100mm(Include 1meter no-power rear roller frame)

Operating air pressure: 0.6~0.8Mpa

Air consumption: 0.4stere/min

Conveyor belt extreme breadth: 304mm

Conveyor height: according to client line (adjustable scope 150mm)

Main performance features

Compact & artistic shape. The frame is novel, unique.

Electronic induction feeding film, action is balanced and quickly replacing film.

Isothermal sealing cutter. The seal intensity is above cooling sealing cutter 3 times, the seal is even and the life is above

cooling sealing cutter 80 times.

Transport system with speed regulation by frequency variation, the transmission action is precise and synchro.

The shrinkage chamber uses centrifugal thermal air circulation system, configuration is logical, heat insulation heat

preservation, thermostat precision is high and the packing effect is better.

Disposition: SIEMENS, OMRON, UNIQUC, etc. advanced control component in the world, Well-equipped.

food, beverage, chemical and office industries

Technical Specification

Packing form: bottles and cans

Packing speed: 10 packs/min

Applicable container shape: circular container, quadrate container

Total power charge: 19kw three-phase-five-line 380v/50Hz

Machine size: L×W×H=6500×3200×2100mm(Include 1meter no-power rear roller frame)

Operating air pressure: 0.6~0.8Mpa

Air consumption: 0.4stere/min

Conveyor belt extreme breadth: 304mm

Conveyor height: according to client line (adjustable scope 150mm)

Main performance features

Compact & artistic shape. The frame is novel, unique.

Electronic induction feeding film, action is balanced and quickly replacing film.

Isothermal sealing cutter. The seal intensity is above cooling sealing cutter 3 times, the seal is even and the life is above

cooling sealing cutter 80 times.

Transport system with speed regulation by frequency variation, the transmission action is precise and synchro.

The shrinkage chamber uses centrifugal thermal air circulation system, configuration is logical, heat insulation heat

preservation, thermostat precision is high and the packing effect is better.

Disposition: SIEMENS, OMRON, UNIQUC, etc. advanced control component in the world, Well-equipped.

FAQ

Q1: which city are you in? how can I get to your factory? Are you a trading company or factory?

A1: We are in Zhangjiagang city, two hours driving from Shanghai. We are factory. Manufacturing mainly beverage filling and packagingmachines. We offer turnkey solutions with more than 10 years experience.

Q2: Why is your prices higher than others?

A2: We offer high-end machines in our business. Welcome to our factory to have a visit. And you will see the difference.

Q3: What is your delivery time?

A3: Normally 30-60 working days depends one machines, water machines are faster, carbonated drink machines are slower.

Q4: How to install my machines when it arrives? How much the cost?

A4: We will send our engineers to your factory to install the machines and train your staff how to operate the machines If needed.Or you can arrange engineers to study in our factory. You are responsible for air tickets, accommodation and our engineer wage USD100/day/person.

Q5: How long time for installation?

A5: Subject to machines and the situation in your factory. If everything is ready, it will take about 10 days to 25 days.

Q6: How about the spare parts?

A6: We will send one year enough easy broken spare parts together with the machines for free, we suggest you buy more units tosave international courier such as DHL, it is really costly.

Q7: What is your guarantee?

A7: We have one year guarantee and life-long technical support. Our service also including machine maintence.

Q8: What is your payment term?

A8: 30%T/T in advance as down payment, rest should be paid before shipping. L/C is supported also.

A1: We are in Zhangjiagang city, two hours driving from Shanghai. We are factory. Manufacturing mainly beverage filling and packagingmachines. We offer turnkey solutions with more than 10 years experience.

Q2: Why is your prices higher than others?

A2: We offer high-end machines in our business. Welcome to our factory to have a visit. And you will see the difference.

Q3: What is your delivery time?

A3: Normally 30-60 working days depends one machines, water machines are faster, carbonated drink machines are slower.

Q4: How to install my machines when it arrives? How much the cost?

A4: We will send our engineers to your factory to install the machines and train your staff how to operate the machines If needed.Or you can arrange engineers to study in our factory. You are responsible for air tickets, accommodation and our engineer wage USD100/day/person.

Q5: How long time for installation?

A5: Subject to machines and the situation in your factory. If everything is ready, it will take about 10 days to 25 days.

Q6: How about the spare parts?

A6: We will send one year enough easy broken spare parts together with the machines for free, we suggest you buy more units tosave international courier such as DHL, it is really costly.

Q7: What is your guarantee?

A7: We have one year guarantee and life-long technical support. Our service also including machine maintence.

Q8: What is your payment term?

A8: 30%T/T in advance as down payment, rest should be paid before shipping. L/C is supported also.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Hot Searches