- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

100/110/220V

-

Dimension(L*W*H):

-

Standard

-

Weight:

-

50 KG

-

Product name:

-

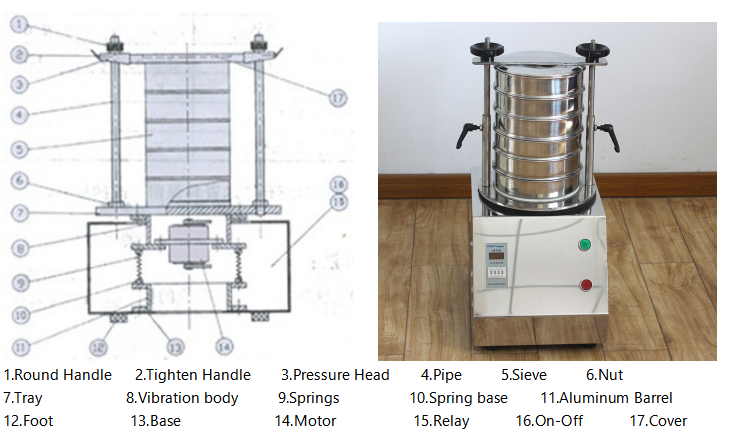

Electronic Lab test equipment mechanical vibrating sieve shaker

-

Material:

-

Stainless Steel

-

screen mesh:

-

0.038-3mm

-

Dimension:

-

400*300*600mm

-

Product name::

-

laboratory test sieve

-

Mesh material:

-

SS304/316/304L/316L,etc

-

Diameter:

-

200mm

-

Usage:

-

lab testing

Quick Details

-

Type:

-

Circular

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Yuecheng

-

Voltage:

-

100/110/220V

-

Dimension(L*W*H):

-

Standard

-

Weight:

-

50 KG

-

Product name:

-

Electronic Lab test equipment mechanical vibrating sieve shaker

-

Material:

-

Stainless Steel

-

screen mesh:

-

0.038-3mm

-

Dimension:

-

400*300*600mm

-

Product name::

-

laboratory test sieve

-

Mesh material:

-

SS304/316/304L/316L,etc

-

Diameter:

-

200mm

-

Usage:

-

lab testing

Brief Introduction

flour laboratory test sieve

are suitable for research and development, quality control of raw materials, intermediate products and end products, and production control. Sieve shakers are designed for grain size determination, separation, and fractionation of powders, bulk goods, and suspensions. They also have high load endurance, extremely quiet operation, and short sieving times with exact separation. Sieving machines feature a maintenance-free electromagnetic drive and three-dimensional movement of the sieve stock due to the tilted spring arrangement. The vibration height can be set infinitely from 0–3mm. These machines are suitable for both wet and dry sieving, and meet all ergonomic requirements for a modern laboratory.

Application

1)Chemical industry: resin, pigment, cosmetic, coatings, Chinese medicine powder,paint

2)Food industry: sugar powder, starch, salt, rice noodle, milk powder, egg powder, sauce, syrup,bread crumbs

3)Metallurgy, Mine industry: aluminum powered, copper powder, ore alloy powder, welding rod powder

4)Medicinal industry: all kinds of medicine

5)Waste treatment: disposed oil, disposed water, disposed dye waste water, active carbon

And many more….

2)Food industry: sugar powder, starch, salt, rice noodle, milk powder, egg powder, sauce, syrup,bread crumbs

3)Metallurgy, Mine industry: aluminum powered, copper powder, ore alloy powder, welding rod powder

4)Medicinal industry: all kinds of medicine

5)Waste treatment: disposed oil, disposed water, disposed dye waste water, active carbon

And many more….

|

No

|

Name

|

Unit

|

Parameters

|

|

1

|

Working diameter

|

mm

|

φ200/φ300

|

|

2

|

Mesh Size

|

mm

|

0.025~3

|

|

3

|

Power

|

kw

|

0.12

|

|

4

|

Noise

|

db

|

<50

|

|

5

|

Amplitude

|

mm

|

0~3

|

|

6

|

Vibration Frequency

|

t/min

|

1400

|

|

7

|

Dimension

|

mm

|

350:380:300+N*50

|

|

8

|

Voltage

|

V/Kz

|

220;50

|

|

9

|

Weight

|

Kg

|

35

|

About Us

Xinxiang Yuecheng Machinery Co., LTD is a standardized enterprise, specializing in kinds of vibrating screen equipment.

Our main products are three dimensional vibration sieve, linear vibrating screen, ultrasonic vibrating screen,

Tumbler sieve,airflow sieve high frequency sieve, sieve, strokes, mud testing screen, vibration motor, conveyor and other

mechanical equipment vibration.

In addition to the conventional series of products, but also provide customers with personalized products and equipment type selection service, widely used in food, medicine, chemical industry, resin, ceramic, metal powder mining and metallurgy, paper-making, ore processing and other industries

Our main products are three dimensional vibration sieve, linear vibrating screen, ultrasonic vibrating screen,

Tumbler sieve,airflow sieve high frequency sieve, sieve, strokes, mud testing screen, vibration motor, conveyor and other

mechanical equipment vibration.

In addition to the conventional series of products, but also provide customers with personalized products and equipment type selection service, widely used in food, medicine, chemical industry, resin, ceramic, metal powder mining and metallurgy, paper-making, ore processing and other industries

Export wooden case.

Ours sieve machine or spare parts will be packed by export wooden case or other package suitable for transport.

FAQ

Q:What factors I need to get a quotation?

A: Material bulk density, mesh size,deck numbers & ideal capacity for proper type, granularity distribution is recommended.

product material requirement (carbon steel Q235A, stainless steel SUS304 or SUS316,etc.) Voltage & Frequency(Hz) is also needed for a precise quotation.

Q:What is the real delivery time of your factory?

A: 7 to 15 days for general series products, meanwhile, batches products & customized products would need 30 days to 60 days based on different situations.

Q: How do you ensure the quality of your products?

A: Generally, our equipments are the most durable type in the industry, this is also the feature of the label impression of

Sanchen for most of our customers at home or abroad.Skilled workers and strict quality control system can ensure every machine with best working performance.

Q: How do your after-sale service work if the product got damaged?

A: In the guarantee time 12 months, our general after-sale service is changing the damaged parts for the customer, but if the damage could be repaired by slight cost, we would wait for the customer's bill for the fix cost and refound this part of

cost.(note: Vulnerable parts do not include.)

Q: How could I trust your promise?

A: Firstly, you may check the assessment on our website certified by the appraisal agency Bureau Veritas;

Secondly, we attend at least 4 to 6 international industry exhibitions held in China annually, like the Food Ingredients China,

China International Battery Fair, CPhI, ICSE BioPh China, ICIF China, etc. We usually met our customers there for negotiation;

Thirdly, company inspection always available, if you have any representative or you would like to come to our site, we offer free shuttle from Zhengzhou airport to our company, welcome your visit.

A: Material bulk density, mesh size,deck numbers & ideal capacity for proper type, granularity distribution is recommended.

product material requirement (carbon steel Q235A, stainless steel SUS304 or SUS316,etc.) Voltage & Frequency(Hz) is also needed for a precise quotation.

Q:What is the real delivery time of your factory?

A: 7 to 15 days for general series products, meanwhile, batches products & customized products would need 30 days to 60 days based on different situations.

Q: How do you ensure the quality of your products?

A: Generally, our equipments are the most durable type in the industry, this is also the feature of the label impression of

Sanchen for most of our customers at home or abroad.Skilled workers and strict quality control system can ensure every machine with best working performance.

Q: How do your after-sale service work if the product got damaged?

A: In the guarantee time 12 months, our general after-sale service is changing the damaged parts for the customer, but if the damage could be repaired by slight cost, we would wait for the customer's bill for the fix cost and refound this part of

cost.(note: Vulnerable parts do not include.)

Q: How could I trust your promise?

A: Firstly, you may check the assessment on our website certified by the appraisal agency Bureau Veritas;

Secondly, we attend at least 4 to 6 international industry exhibitions held in China annually, like the Food Ingredients China,

China International Battery Fair, CPhI, ICSE BioPh China, ICIF China, etc. We usually met our customers there for negotiation;

Thirdly, company inspection always available, if you have any representative or you would like to come to our site, we offer free shuttle from Zhengzhou airport to our company, welcome your visit.

Please show us the following answers ,so that we can direct make a quoation for you .

Your company details contact infomation .such as email address ,and phone No.

1. Screen Material ?

2.Layers?

3. Mesh size each layer?

4. Capacity : _______KG/H

5. Moisture ,viscous ,corrosive.....

6. Voltage: _______V, ______HZ,3 phase.

7. Carbon Steel ,SS304.SS316...

Your company details contact infomation .such as email address ,and phone No.

1. Screen Material ?

2.Layers?

3. Mesh size each layer?

4. Capacity : _______KG/H

5. Moisture ,viscous ,corrosive.....

6. Voltage: _______V, ______HZ,3 phase.

7. Carbon Steel ,SS304.SS316...

Hot Searches