- Product Details

- {{item.text}}

Quick Details

-

Return Force (kN):

-

300 kN

-

Place of Origin:

-

China

-

Year:

-

2020

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

900x1500x2400

-

Weight (T):

-

6 T

-

Model Number:

-

Y41-100T

-

Motor Power (kw):

-

7.5 kw

-

Applicable Industries:

-

machine tool

-

Product name:

-

Hydraulic Punching Machine

-

Type:

-

Single Column Hydraulic Press

-

Material:

-

Steel Material

-

Function:

-

Punching Ang Press

-

Model:

-

Y41-100T

-

Safety protection:

-

Photoelectric protection

-

Application:

-

Auto Parts

-

Keyword:

-

Hydryalic Press Machine

-

Advantage:

-

High Efficiceny

-

Certification:

-

CE/ISO

Quick Details

-

Machine Type:

-

Single Column Hydraulic Press

-

Slide Stroke (mm):

-

500

-

Ejector Force (kN):

-

1000

-

Return Force (kN):

-

300 kN

-

Place of Origin:

-

China

-

Year:

-

2020

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

900x1500x2400

-

Weight (T):

-

6 T

-

Model Number:

-

Y41-100T

-

Motor Power (kw):

-

7.5 kw

-

Applicable Industries:

-

machine tool

-

Product name:

-

Hydraulic Punching Machine

-

Type:

-

Single Column Hydraulic Press

-

Material:

-

Steel Material

-

Function:

-

Punching Ang Press

-

Model:

-

Y41-100T

-

Safety protection:

-

Photoelectric protection

-

Application:

-

Auto Parts

-

Keyword:

-

Hydryalic Press Machine

-

Advantage:

-

High Efficiceny

-

Certification:

-

CE/ISO

Product Description

Machine for stainless steel pot making press machine

One kind of multifunctional medium-small hydraulic press.

It can be used in bearings and moulding, also suitable for bearings and sleeves.

At the same time,the machine can complete the technology function of bending, shelling of plate material parts, stretching of simple parts, pressing powder, plastic products, etc.

It is mainly suitable for metal sheet curveting, flattening, stretching, stamping, shaft parts coupling, powder and plastic

forming. This product is applied in the machine tool, automotive, motor vehicles, air-conditioned shell, mechanical bearings,powder metallurgy, and plastic industry.

Main Features

1. Single column C-frame structure hydraulic presses to make work safely.

2. Entire steel welded with tempering treatment for stable.

3. Cartridge valve integrated hydraulic system: long service life, return leak point.

4. Hydraulic system equipped with pre-release device to reduce hydraulic force impact.

5. Operation button centralized control and equipped with adjusting and semi-auto model.

6. Equipped with single-constant stroke and pressure function.

7. CNC control system makes working efficiently.

1. Single column C-frame structure hydraulic presses to make work safely.

2. Entire steel welded with tempering treatment for stable.

3. Cartridge valve integrated hydraulic system: long service life, return leak point.

4. Hydraulic system equipped with pre-release device to reduce hydraulic force impact.

5. Operation button centralized control and equipped with adjusting and semi-auto model.

6. Equipped with single-constant stroke and pressure function.

7. CNC control system makes working efficiently.

Specification

|

No

|

Items

|

Unit

|

Y41-40

|

Y41-63

|

Y41-100

|

Y41-160

|

Y41-200

|

Y41-250

|

|

1

|

Nominal force

|

KN

|

400

|

630

|

1000

|

1600

|

2000

|

2500

|

|

2

|

Throat depth

|

mm

|

320

|

320

|

340

|

325

|

350

|

400

|

|

3

|

Max open height

|

mm

|

700

|

700

|

900

|

1000

|

1000

|

1000

|

|

4

|

Slide stroke

|

mm

|

500

|

500

|

500

|

500

|

600

|

600

|

|

5

|

Worktable size

|

mm

|

580x560

|

580x560

|

750x630

|

750x630

|

800x650

|

850x700

|

|

6

|

Slide speed (Return)

|

mm/s

|

135

|

95

|

118

|

100

|

65

|

80

|

|

7

|

Slide speed (Pressing)

|

mm/s

|

12

|

10

|

10

|

8

|

4

|

3.7

|

|

8

|

Table Hight above floor

|

mm

|

650

|

650

|

700

|

650

|

700

|

700

|

|

9

|

Motor power

|

KW

|

5.5

|

7.5

|

11

|

15

|

15

|

15

|

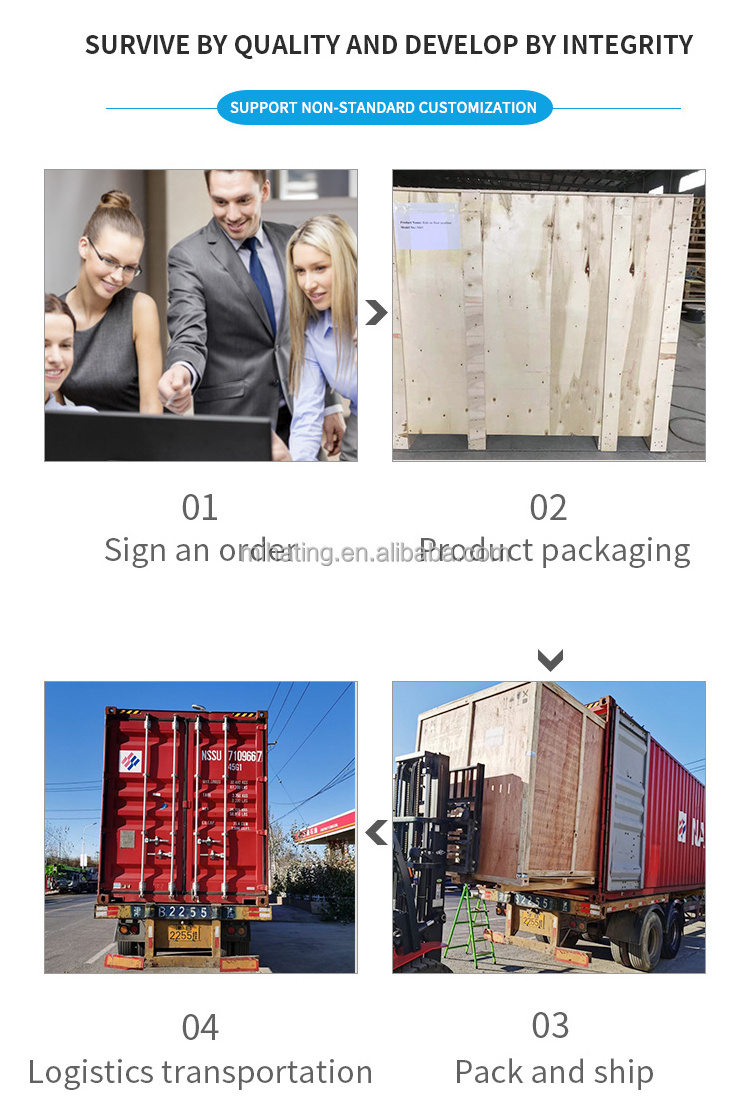

Packing & Delivery

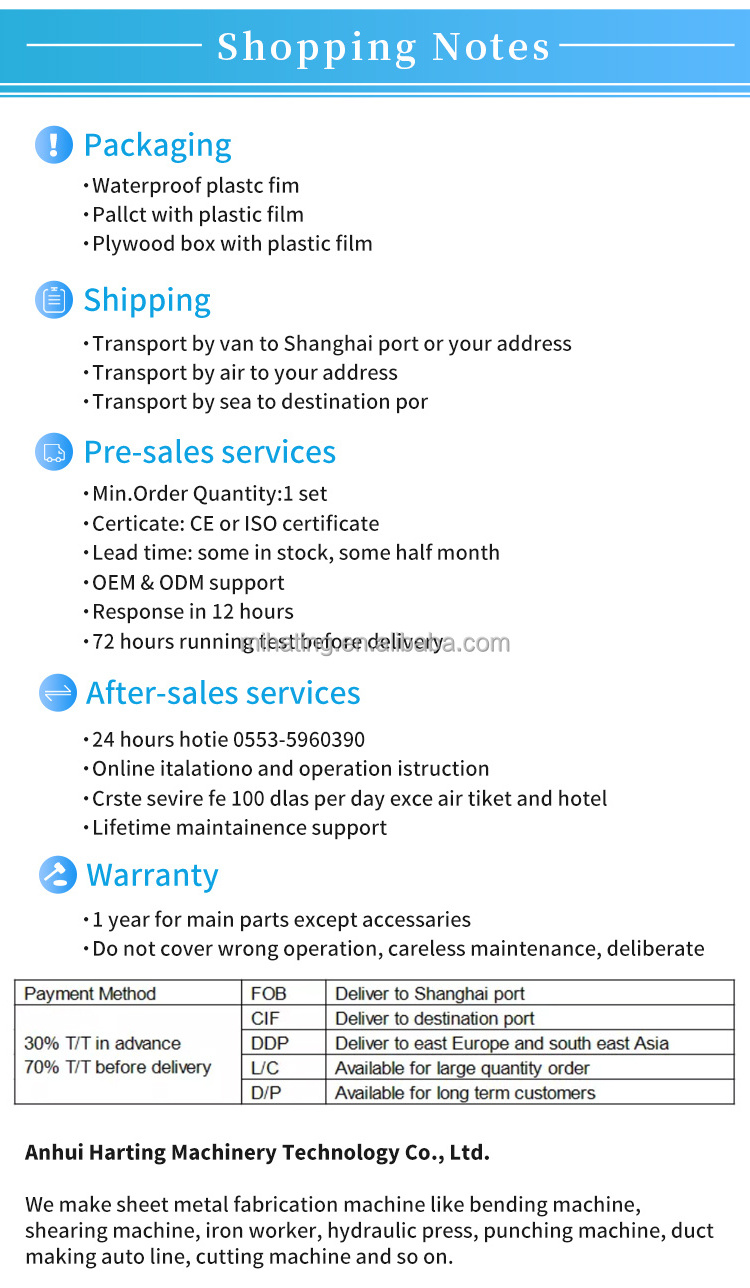

Packaging Details:

Plastic film, wooden package, or as requirement.

Delivery Detail: 15 days

Plastic film, wooden package, or as requirement.

Delivery Detail: 15 days

Pre-sales Service

1. Inquiry and consulting support.

2. Sample testing support .

3. Recommend the most suitable machine according to customer's purpose.

4. Factory visiting welcomed.

After-sales Service

1. Training how to install the machine .

2. Training how to use the machine .

3. Warranty 1 year.

4. Engineers available to service machinery oversea .

1. Inquiry and consulting support.

2. Sample testing support .

3. Recommend the most suitable machine according to customer's purpose.

4. Factory visiting welcomed.

After-sales Service

1. Training how to install the machine .

2. Training how to use the machine .

3. Warranty 1 year.

4. Engineers available to service machinery oversea .

Hot Searches