- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

±1%

-

Packaging Type:

-

Cup

-

Voltage:

-

220V, 220V, 50/60Hz

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

MK Machine

-

Dimension(L*W*H):

-

1250(L)*1250(W)*1650(H)mm

-

Weight:

-

280 KG

-

Product name:

-

Cup filling sealing machine

-

Usage:

-

Liquid cup filling sealing machine

-

Keywords:

-

Cup filling sealing machine

-

Automaticity:

-

Full aotumatic

-

Gas consumption:

-

0.4-0.6m³/min

-

Working speed:

-

1600-2000BPH

-

Filling volume:

-

10-300ml(customized)

Quick Details

-

Machinery Capacity:

-

1600-2000BPH

-

Packaging Material:

-

Plastic

-

Filling Material:

-

Beer, Other, Milk, Water, Oil, Juice, Jam, Honey, Sauce, Paste

-

Filling Accuracy:

-

±1%

-

Packaging Type:

-

Cup

-

Voltage:

-

220V, 220V, 50/60Hz

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

MK Machine

-

Dimension(L*W*H):

-

1250(L)*1250(W)*1650(H)mm

-

Weight:

-

280 KG

-

Product name:

-

Cup filling sealing machine

-

Usage:

-

Liquid cup filling sealing machine

-

Keywords:

-

Cup filling sealing machine

-

Automaticity:

-

Full aotumatic

-

Gas consumption:

-

0.4-0.6m³/min

-

Working speed:

-

1600-2000BPH

-

Filling volume:

-

10-300ml(customized)

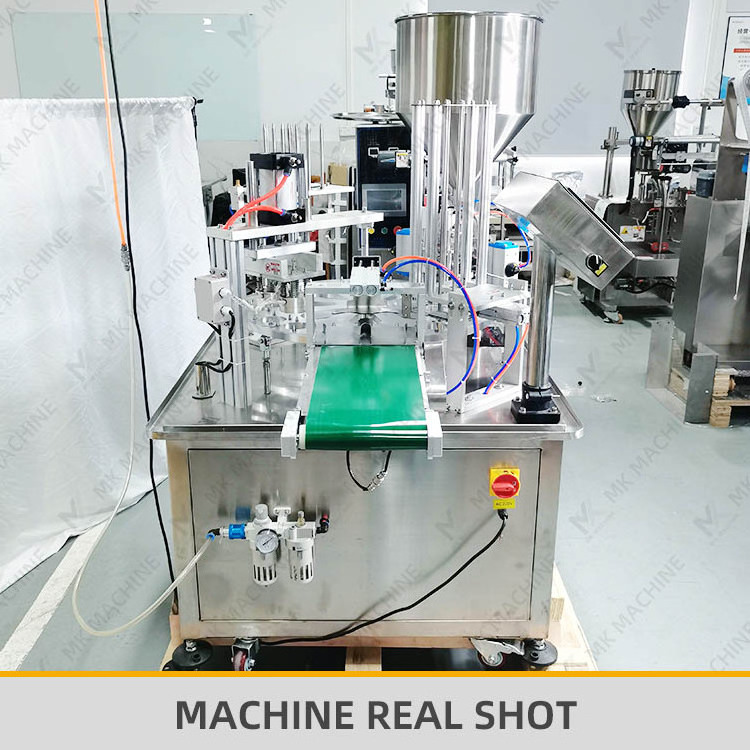

Fully automatic liquid yogurt plastic cup filling and sealing machine

1. Independent turntable design, small footprint, easy to detect and maintain.

2. Intelligent PLC control system, fully automatic operation, higher production efficiency.

3. Use touch screen to set parameters, support multiple languages, simple operation.

4. PID independently controls the temperature, suitable for various sealing materials.

5. Using brand high-quality electrical components, the machine is reliable and durable.

6. Multiple automatic alarm functions to minimize material loss.

|

Working speed

|

1600-2000 piece/hour (depending on the weight of the material)

|

|

Filling volume

|

10-300ml(customized)

|

|

Power

|

220V, 50/60Hz, 2kw

|

|

Gas consumption

|

0.4-0.6m³/min

|

|

Dimension

|

1250(L)*1250(W)*1650(H)mm

|

|

Machine weight

|

280kg

|

This machine is suitable for packaging in food, daily necessities and other industries, such as honey, tomato sauce, jam, seasoning sauce, tartar sauce, chili sauce, fish sauce, fruit juice, yogurt, milk, ice cream, jelly, cream, liquid butter, nutrient solution, mouthwash, skin care lotion, etc.

Cup Drop Device

Support multiple sizes of cups, automatically detect and drop cups, and automatically stop and alarm when there is no cup.

Filling Head

Adopt plunger type metering pump to perform filling, with high precision and anti-drip device.

Film Taking Device

Take out the parafilm with a vacuum suction cup and place it exactly on top of the cup.

Sealing Device

PID independent temperature control, temperature can be set according to different sealing materials.

An operation video is prepared for you, and a product manual is attached.

Professional engineers provide technical support to customers.Customers can contact us immediately if they have any questions.

Foshan Maike Intelligent Equipment Co., Ltd. is located in Nanhai District, Foshan City, the center of China's machinery manufacturing industry. It is a high-tech enterprise integrating R&D, manufacturing, sales and after-sales service.

The company strictly implements the international quality management system and standard standardized production system, and its leading products have passed the EU CE, ROHS, SGS and other mark certifications. The company's products sell well in 97 countries and regions around the world, and have established long-term strategic cooperative dealer service systems in many countries around the world.

FAQ

1.How to find a solution suitable for my product?

Tell me about your product details: 1. What kind of product you have. 2. the size of your product.

2.How easy is it to operate packaging equipment?

2.How easy is it to operate packaging equipment?

The good news is that as long as your packaging system isn't hyper-customized, the equipment is pretty easy to use! Most of our equipment does not require advanced technical knowledge to operate.

3.How much does packaging equipment cost?

3.How much does packaging equipment cost?

There is no quick, easy answer to this question. Packaging machinery is specific to the customer, so arriving at 'standard pricing' isn't usually practical. Pricing largely depends upon your unique needs, such as the products you want to package, the speeds you would like to achieve, your sizes or the complexity of your process.

4.Which machines are available in-stock?

4.Which machines are available in-stock?

If your needs are fairly standard and straightforward, you may be able to snag an In-Stock Machine and get it delivered in just a few weeks! CALL US to ask about our current inventor

y.

5.What is your after sales services?

5.What is your after sales services?

●

After finish the production, we will debug the production line, take photos, videos and send them to customers via mail or instant tools.

●

After the commissioning, we will package the equipment by standard export package for shipment.

●

According to the customer's request, we can arrange our engineers to customers' factory to do the

installation and training.

installation and training.

●

Engineers, sales managers and after-sales service manager will form a after-sales team, online and off line, to follow the customers' project.

Hot Searches