- Product Details

- {{item.text}}

Quick Details

-

Product Name:

-

press felt for tissue paper making felt paper mill dryer felt

-

Material:

-

Polyester

-

Type:

-

Make-to-order

-

Size:

-

Customer`s Requirement

-

Function:

-

Paper Mill Dryer Belt

-

Width:

-

0.5-12.5m (customized)

-

Felt GSM:

-

600~1450g/m2

-

Air Permeability:

-

30~110cfm

-

Tensile Strength:

-

≥3000N/5cm

-

Elongation Percentage:

-

≤0.6%

Quick Details

-

Weight (KG):

-

30

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Meida

-

Product Name:

-

press felt for tissue paper making felt paper mill dryer felt

-

Material:

-

Polyester

-

Type:

-

Make-to-order

-

Size:

-

Customer`s Requirement

-

Function:

-

Paper Mill Dryer Belt

-

Width:

-

0.5-12.5m (customized)

-

Felt GSM:

-

600~1450g/m2

-

Air Permeability:

-

30~110cfm

-

Tensile Strength:

-

≥3000N/5cm

-

Elongation Percentage:

-

≤0.6%

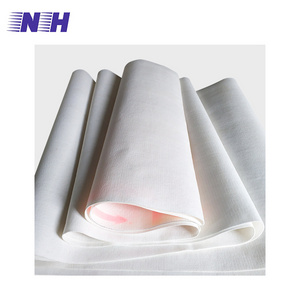

press felt for tissue paper making felt paper mill dryer felt

It is mainly used in drying part, shipping and filtering of other parts for making paper. It is a device for forming and dewatering paper on paper machine. It dehydrates the pulp suspension from the headbox and runs the paper web to the subsequent section.

Advantages of Paper Making Felt:

1. Long service life, wear resistance and Acid and alkali resistance,low consumption.

2. High anti-compaction capacity,Extremely high elasticity and recoverability.

3.Smooth felt surface and even pressure distributio

4.Strong drainability abd larger void volumn

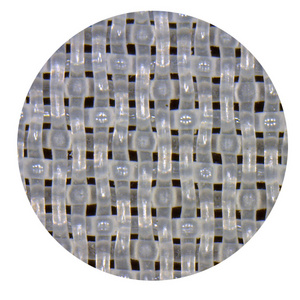

5. The mesh marks are light and the molding quality is good.

Brief Introduction of Paper Felt

According there structures,they can be divided into BOM formed felt,BOM pressed felt,BOM upper felt,BOM dryer felt and so on.

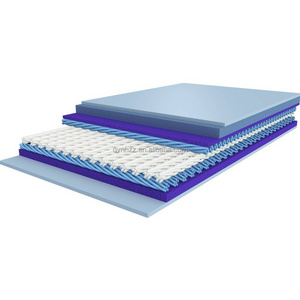

BOM paper making felts are generally made of the base mesh layer and the fiber layer.The base mesh can be single,double or multilayers.

The double base mesh layer can also have a 1+1 laminated. The multi layer base mesh can also be divided into 1+2 or 2+2 laminated.

| Product Name | BOM felt , single layer , double layer, triple layer of paper making felt |

| Use position | Pick up felt,MG felt,Dryer felt,Press felt |

| Material | Nylon / Synthetic Filament Or Multi-filament |

| Paper machin part | Cylinder \Super forming\ Fourdrinier\ Inclined wire machinel Nip wire machine for forming section felt \ Press felt |

| Width | 0.5-12.5m (customized) |

| Felt GSM | 600~1450g/m2 |

| Air Permeability | 30~110cfm |

| Tensile Strength | ≥3000N/5cm |

| Elongation Percentage | ≤0.6% |

Press felt for tissue paper making felt paper mill dryer felt

Using Method and Maintenance of Paper Making Felt

1. Compare specification, size and weight with required standard

2. Find the facade with sign "The Side with Paper" before using, don't reverse it and operate it according to the arrow.

3. Wrap the top of oiled axle with plastic bag while fixing, don't be soiled with grease; if there is grease, please wash it with gas before operating.

4. The felt must be spread and sprinkled with water before pressing. When it is evenly wetted, strain it and slowly operate the machine.

5. Press the felt before adding paper. Meanwhile, soften the polyamide fiber of felt surface with soda water to improve its adaptability.

6. Adopt the way of double-sides sprinkling to wash felt. Adopt high pressure (5~20kgf/cm2)moving sprinkling pipe to wash the reverse side; and adopt frequent pressure(1~3 kgf/cm2)fan sprinkling to wash the obverse side.

7. In normal operation, the standard line is straight, if not, please correct to avoid affecting the quality. Correcting method: strain the front side of standard line according to the operating direction; soften the back of standard line. Adjust a little once until finding standard line is level and straight.

8. After used for a period, the felt should be washed regularly, and choose special detergent for different felt. Wash alkaline felt with acid detergent, acid one with alkaline detergent; neutral one with non-ion active detergent. To the special part, adopt the high-pressure water-gun to sprinkle.

Packaging: plastic burlap bags, wooden boxes, containers

Transportation: express delivery, air freight, sea freight

Pre-Sales Service

1.Offering comprehensive technical and business consultation services

2.Proposing the most suitable scheme and equipment for our clients

3.Designing and fabricating targeted products according to the special requirements of clients

After-Sales Service

1.Highly inspecting equipments in every working procedure, quality comes first

2.Fast & Safe Delivery

3.Dispatching engineers to install and debug equipments

4.Training the first-line operators

5.Regularly visit clients to solve production problems

6.Providing life-long maintenance service and technical exchanging