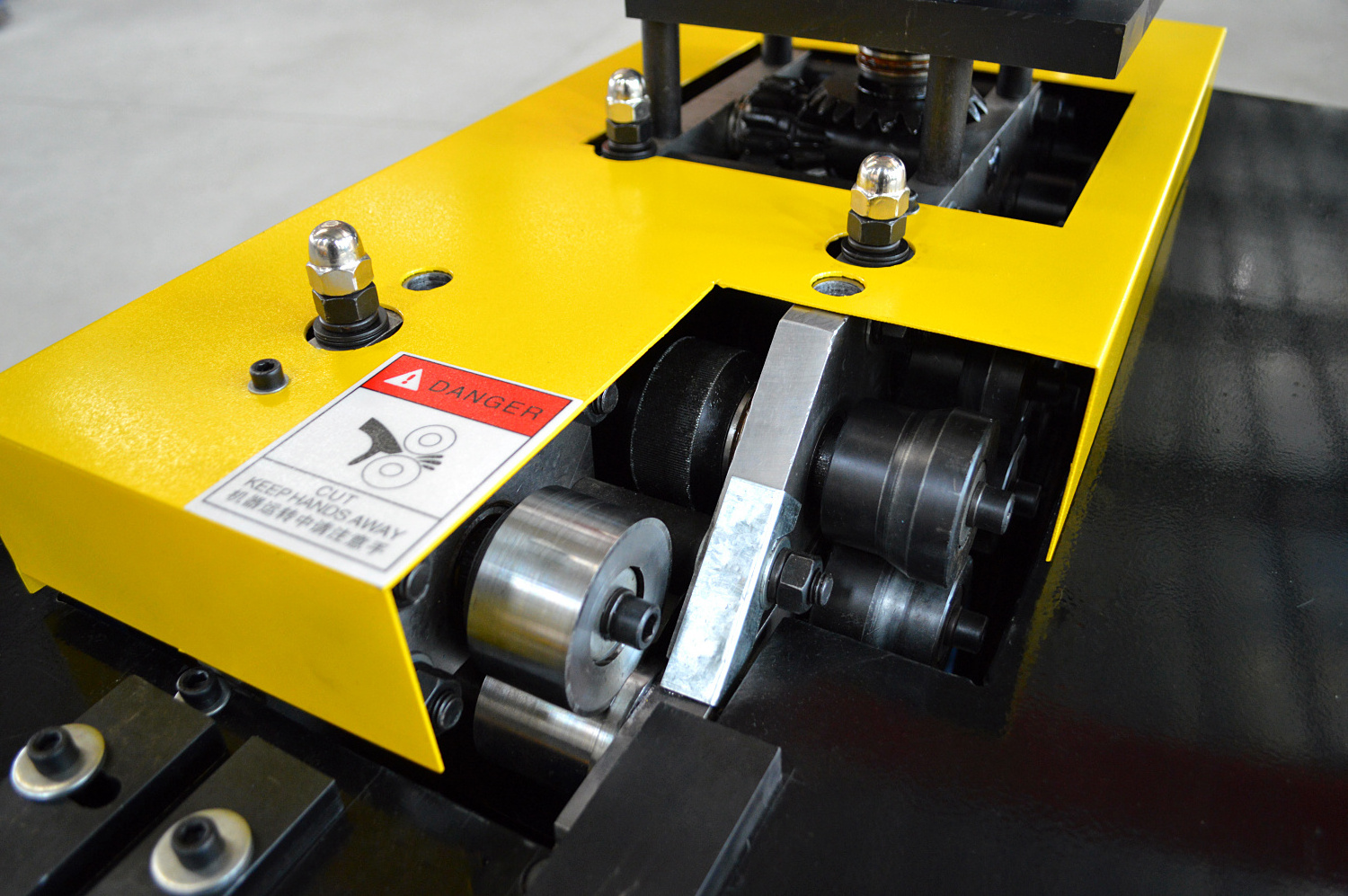

Locking machine is necessary in duct area because it can produce all kinds of types to meet locking requirements. Standard machine can process 0.5-1.5mm galvanized sheet metal, and our company would specially introduce high-strength rolling reels made of GCr15, a kind of steel which prolongs the machine life by more than 5 times and improve the efficiency dramatically.

- Product Details

- {{item.text}}

Quick Details

-

Sheet thickness:

-

0.5-1.5mm

-

Power:

-

1.5-2.2kw

-

Weight:

-

200-280kgs

-

Function:

-

Pittsburgh forming

-

Machine name:

-

Lock forming machine

-

Processing Material:

-

Stainess/Galvanized steel

Quick Details

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

SUNTAY

-

Model:

-

SA-12HB

-

Sheet thickness:

-

0.5-1.5mm

-

Power:

-

1.5-2.2kw

-

Weight:

-

200-280kgs

-

Function:

-

Pittsburgh forming

-

Machine name:

-

Lock forming machine

-

Processing Material:

-

Stainess/Galvanized steel

Pittsburgh lock former machine lock forming machine

|

Model

|

SA-12HB

|

|

Sheet thickness(mm)

|

0.5-1.2

|

|

Power(kw)

|

1.5

|

|

Weght(kg)

|

220

|

|

Dimension9(mm)

L*W*H

|

1050*570*1020

|

Normalized multi-function locking machine

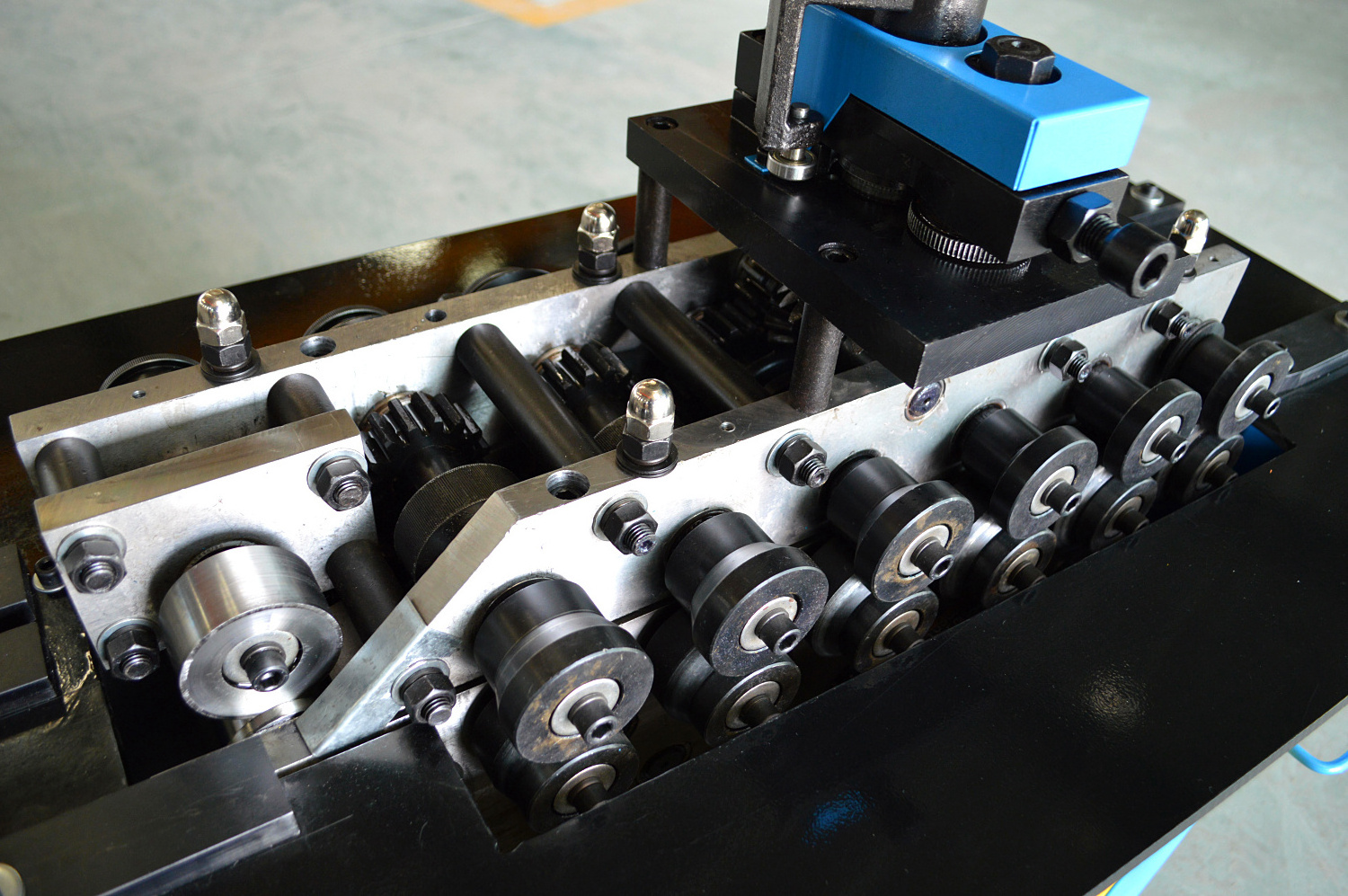

The rolling wheel is made of 45# carbon steel, which is processed by oil quenching heat treatment, and its hardness reaches to 40-60 degrees. The service life is 2-3 years.

Bearing steel locking machine

The material of the pressure wheel is bearing steel GCR15, which is processed by vacuum heat treatment。After that we process it second time , It will become small runout and fine forming. The hardness reaches 55-60 degrees and the service life increases to 3-5 years.

Motor

We use a copper motor with high power, strong power, low noise, low vibration, easy to conduct electricity, high precision rotor output more stable.

Elbow detail

The forming wheel is made of bearing steel GCR15 with a hardness of 55-60 degrees, forming more stable and durable. Wear plate is spring and heat treatment, hardness is 50-55 degrees,It’s more durable.

Gear

The gear is made of 40CR with 45-50 degrees hardness.The Inner hole is fine grinding, low noise and durable. It also has high strength

Guiding ruler

The guiding ruler material is high quality spring steel with hardness of 55-60 degrees, It's Durable after oil quenching and heat treatment

Hot Searches