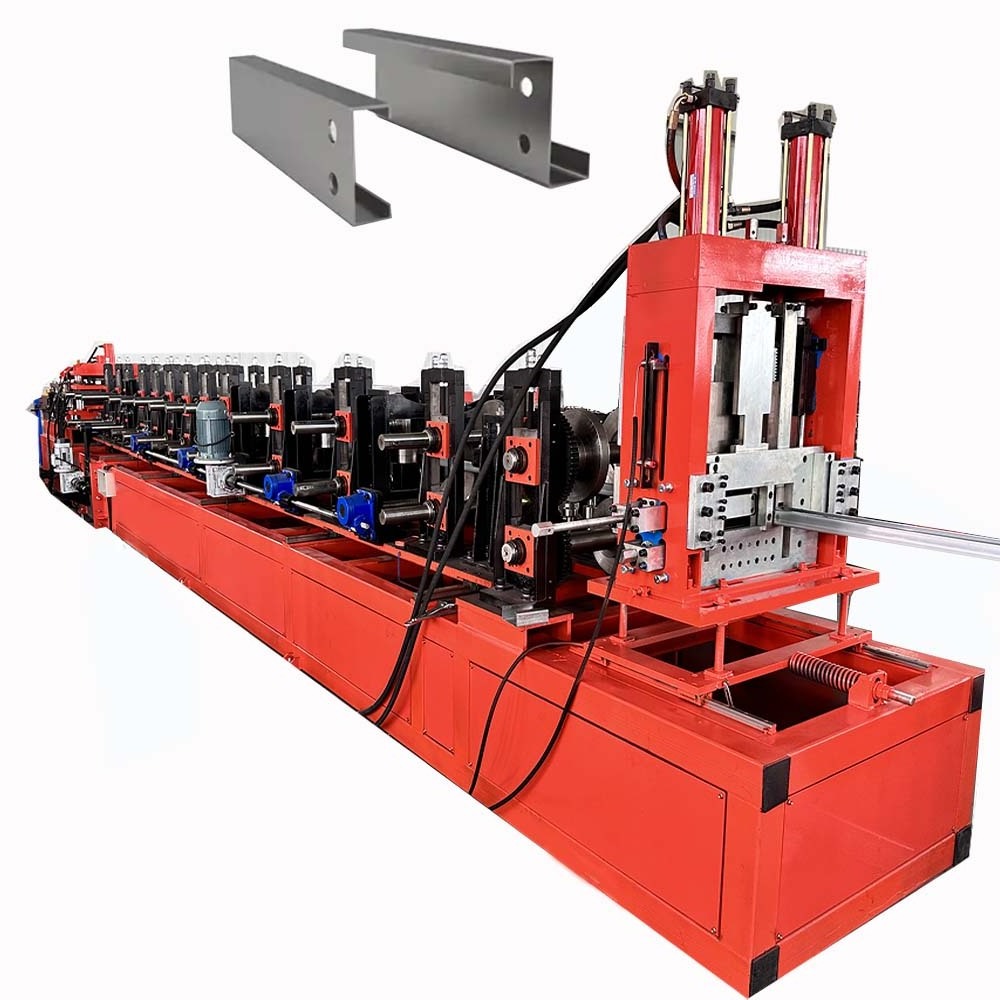

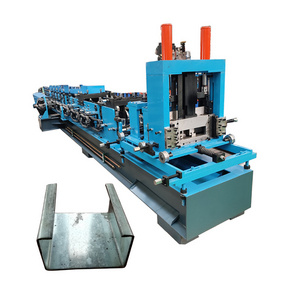

C Z purlin roll forming machine adopts welded steel frame structure, it make sure roof sheet machine can operation more stable

AC frequency conversion motor reducer drive, chain transmission, roller surfaces polishing, hard plating, heat treatment and chrome coating.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Hokang

-

Voltage:

-

220v/380v

-

Power:

-

7500W

-

Dimension(L*W*H):

-

11500*1100*1700

-

Weight:

-

9000 kg

-

Product name:

-

Cz purlin roll forming machine

-

Motor power:

-

22KW

-

Effective plate width:

-

80-300mm

-

Waist height:

-

30-80mm

-

Thickness of feed plate:

-

1.5-3.0mm

-

Discharging speed:

-

8-15m/min, excluding punching and shearing

-

Molding passes:

-

16

-

Spindle diameter:

-

75mm

-

Main frame:

-

400 channel steel

-

Cutter material:

-

Cr12 bearing steel heat treatment

Quick Details

-

Marketing Type:

-

New Product

-

Production Capacity:

-

20 m/min

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Hokang

-

Voltage:

-

220v/380v

-

Power:

-

7500W

-

Dimension(L*W*H):

-

11500*1100*1700

-

Weight:

-

9000 kg

-

Product name:

-

Cz purlin roll forming machine

-

Motor power:

-

22KW

-

Effective plate width:

-

80-300mm

-

Waist height:

-

30-80mm

-

Thickness of feed plate:

-

1.5-3.0mm

-

Discharging speed:

-

8-15m/min, excluding punching and shearing

-

Molding passes:

-

16

-

Spindle diameter:

-

75mm

-

Main frame:

-

400 channel steel

-

Cutter material:

-

Cr12 bearing steel heat treatment

Products Overview

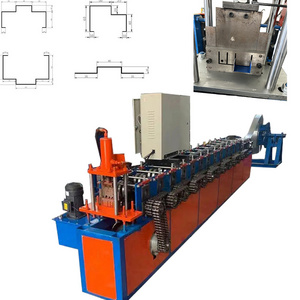

CZ Purlin roll forming machine with multiple shapes in one machine

The full-automatic CZ interchangeable section steel forming machine can exchange the CZ section steel, realize the rapid type change of any model of 80-300mm within one minute, and meet the product type change specification you need. The forming cutter can realize the endless cutting of any model of 80-300, without changing the cutter. Automatic centering and adjustment of feeding port, fixed length cutting, accurate precision, fast molding speed, saving labor cost and improving production efficiency.

1. Feeding: guide shaft + guide wheel

2. Leveling: three up and four down + two leads.

Material: 45#

Processing technology: rough turning + high frequency heat treatment hrc50-55 + cylindrical fine grinding + surface polishing and hard chromium plating

3. Main molding: 18 component type (one of which is waist height molding 87-95 degree arbitrary roll adjustment group), equipped with 13 groups of CZ exchange modules, which can be switched by rotating 180 degrees, and the specification can be changed through the electric button.

4. Pressing bar: straight bar

5. Alignment: Ten roll CZ special two axis alignment + four roll two axis alignment, a total of two alignment units

6. Guiding: equipped with transmission, driven by upper and lower shaft gears

7. Punching: punching single hole + punching double holes after forming, with round holes Φ 14mm and Φ 16mm and oval hole 28 ×16mm and 28 × 14mm optional.

8. Cutting: endless cutting system after forming, cutting does not need to change the knife, and manual type change is required.

Cutter material: Cr12

2. Leveling: three up and four down + two leads.

Material: 45#

Processing technology: rough turning + high frequency heat treatment hrc50-55 + cylindrical fine grinding + surface polishing and hard chromium plating

3. Main molding: 18 component type (one of which is waist height molding 87-95 degree arbitrary roll adjustment group), equipped with 13 groups of CZ exchange modules, which can be switched by rotating 180 degrees, and the specification can be changed through the electric button.

4. Pressing bar: straight bar

5. Alignment: Ten roll CZ special two axis alignment + four roll two axis alignment, a total of two alignment units

6. Guiding: equipped with transmission, driven by upper and lower shaft gears

7. Punching: punching single hole + punching double holes after forming, with round holes Φ 14mm and Φ 16mm and oval hole 28 ×16mm and 28 × 14mm optional.

8. Cutting: endless cutting system after forming, cutting does not need to change the knife, and manual type change is required.

Cutter material: Cr12

Specification

|

No

|

Item

|

Data

|

|

1

|

Equipment size

|

11500*1350*1750mm

|

|

2

|

Weight

|

9t

|

|

3

|

Motor power

|

22KW

|

|

4

|

Effective plate width

|

80-300mm

|

|

5

|

Waist height

|

30-80mm

|

|

6

|

Thickness of feed plate

|

1.5-3.0mm

|

|

7

|

Discharging speed

|

8-15m/min, excluding punching and shearing

|

|

8

|

Molding passes

|

16

|

|

9

|

Feeding material

|

Q195/Q235 hot rolled strip steel

|

|

10

|

Forming roller

|

GCr15 bearing steel finish machining and heat treatment, hard chromium plating, wire drawing and polishing

|

|

11

|

Forming spindle

|

40Cr fine machining, quenching and tempering, hard chromium plating

|

|

12

|

Spindle diameter

|

75mm

|

|

13

|

Main frame

|

400 channel steel

|

|

14

|

Cutter material

|

Cr12 bearing steel heat treatment

|

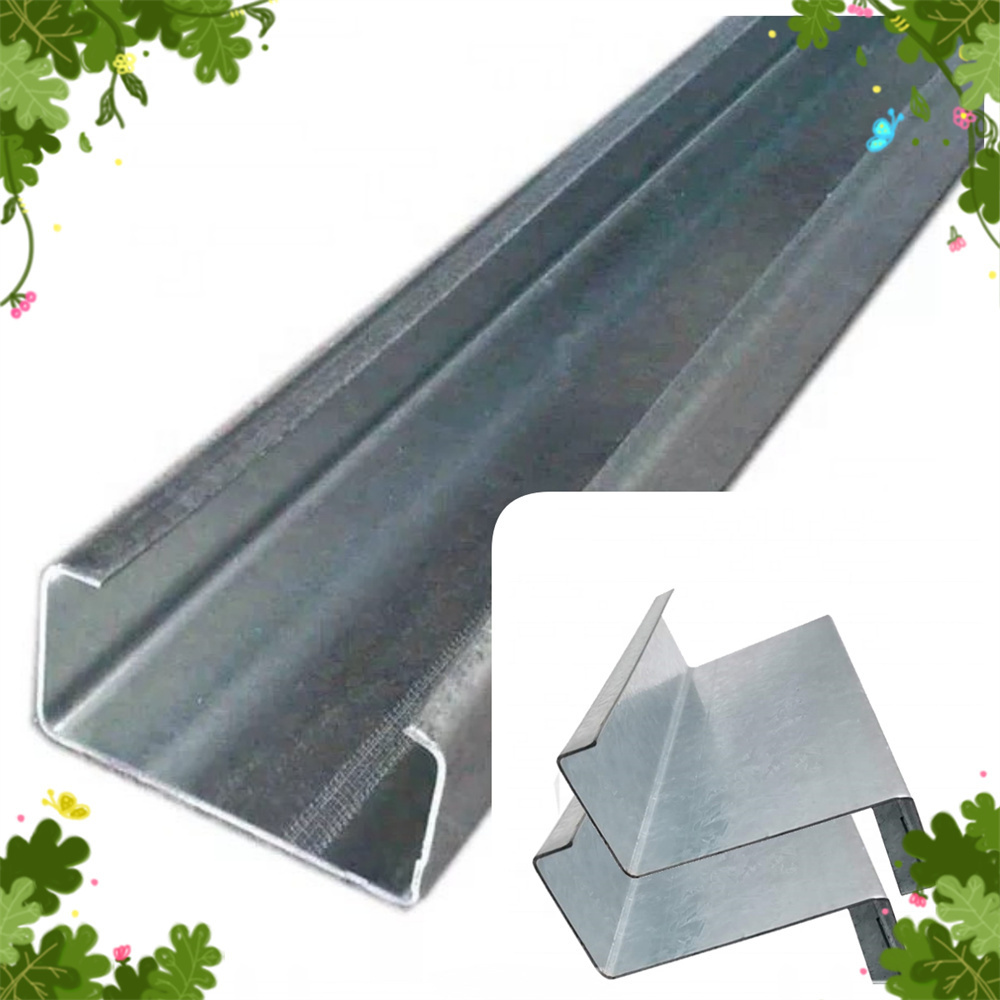

1. Product specification:

1). C width (80-300mm) and Z width (120-300mm) can be changed arbitrarily Replace;

2).Waist height (40-80mm) can be changed arbitrarily;

3). Small side (10-25mm);

4). Plate thickness t(1.5-3.0mm) adjustable

2. Discharging speed: high speed 25m / min (according to the number of holes punched)

3. Applicable material: Q195, Q235 hot rolled strip steel or hot rolled galvanized strip steel (1.5-3.0mm)

1). C width (80-300mm) and Z width (120-300mm) can be changed arbitrarily Replace;

2).Waist height (40-80mm) can be changed arbitrarily;

3). Small side (10-25mm);

4). Plate thickness t(1.5-3.0mm) adjustable

2. Discharging speed: high speed 25m / min (according to the number of holes punched)

3. Applicable material: Q195, Q235 hot rolled strip steel or hot rolled galvanized strip steel (1.5-3.0mm)

Support customization!!! For example profiled, color, logo,Just tell us what you need~

You can provide design drawings, or tell us the material, profiled, feeding width and thickness, and we will customize for you.

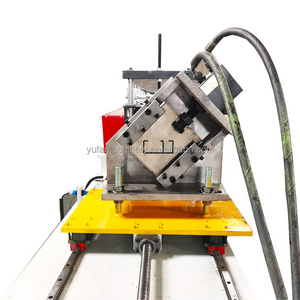

Details Images

Machine Frame Of

Roll Forming Machine

Forming Roller Of

Roll Forming Machine

C Z purlin roll forming machine forming roll quality will decide roof sheet shapes, we can according to your local roof shape

customized different type rollers

Roller chrome coated thickness: 0.05 mm

Roller material: Forging Steel 45# heat treatment.

customized different type rollers

Roller chrome coated thickness: 0.05 mm

Roller material: Forging Steel 45# heat treatment.

Decoiler

Of Roll Forming Machine

C Z purlin roll forming machine load parts, decoiler loading frame we can offer different type can choose. standard type are manual,also can choose electric loading frame or hydraulic loading frame.

This loading frame decoiler also can use in other type machine, customer can buy it alone.

This loading frame decoiler also can use in other type machine, customer can buy it alone.

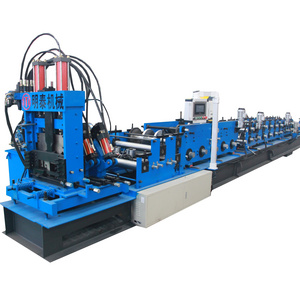

Control Part Of

Roll Forming Machine

C Z purlin roll forming machine control parts have different types, standard type are button control, through press buttons to

realize different function.

realize different function.

PLC touch screen type can setting data on the screen, its price is little higher, but is more intelligent and automatic.

Why Choose Us

♥ Over 20 years of experience.

♥ Customized according to customer requirements with OEM ODE Services.

♥ Favorable price and easy operation.

♥ For many years, we have always adhered to quality first and service foremost, and have developed high-quality agents in

Chile,Brazil, the Philippines, Malaysia, India, and other countries

♥ Professional technical team strictly controls every step of production to ensure the quality of each equipment.

♥ Provide technical guidance, production, installation, commissioning and maintenance services for our customers.

Our Technical Personnel Provide On-Site Services Overseas:

Our technical personnel arrive at the customer's site in Malaysia for technical guidance and training,If a customer encounters technical problems that are difficult to solve during use, we usually send professional and technical personnel to foreign customer sites for guidance and training. Therefore, if you want to do business in cold bending forming equipment, please feel free to contact our customer service personnel at any time.

♥ Customized according to customer requirements with OEM ODE Services.

♥ Favorable price and easy operation.

♥ For many years, we have always adhered to quality first and service foremost, and have developed high-quality agents in

Chile,Brazil, the Philippines, Malaysia, India, and other countries

♥ Professional technical team strictly controls every step of production to ensure the quality of each equipment.

♥ Provide technical guidance, production, installation, commissioning and maintenance services for our customers.

Our Technical Personnel Provide On-Site Services Overseas:

Our technical personnel arrive at the customer's site in Malaysia for technical guidance and training,If a customer encounters technical problems that are difficult to solve during use, we usually send professional and technical personnel to foreign customer sites for guidance and training. Therefore, if you want to do business in cold bending forming equipment, please feel free to contact our customer service personnel at any time.

Product Application

C Z purlin roll forming machine is widely used in the construction of various industrial plants, villages, warehouses, supermarkets, hotels, exhibition, family construction, shopping malls shutter doors and etc. It has the advantage of beautiful, classical appearance and grace taste.

Hot Searches