Update loading system. This is the way to drop the cup in the European machine, which improves the fluency of the machine, reduces the probability of stuck cup, and makes the machine run at high speed.

- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

±0.2g

-

Packaging Type:

-

k cup, nespresso, DG, coffee capsule

-

Voltage:

-

220V/380V

-

Place of Origin:

-

China

-

Brand Name:

-

EXPAK

-

Dimension(L*W*H):

-

2990X1200X2250mm

-

Weight:

-

3000 KG

-

Product name:

-

Coffee Capsule Filling Line

-

Usage:

-

K cup Nespresso Custom Coffee Capsule Cup

-

Suitable for:

-

Ground Coffee Packaging

-

Capacity:

-

12000cups/h

-

Material:

-

Stainless Steel304

-

Control:

-

Servo Motor Control Filling Volume

-

Packing type:

-

plastic aluminum coffee capsule

-

Model Number:

-

CP5004

-

After Warranty Service:

-

Video technical support

-

After-sales Service Provided:

-

Field maintenance and repair service

Quick Details

-

Machinery Capacity:

-

12000Cups/H

-

Packaging Material:

-

Plastic

-

Filling Material:

-

Other, Oil, Powder, tea, broken tea, ground coffee

-

Filling Accuracy:

-

±0.2g

-

Packaging Type:

-

k cup, nespresso, DG, coffee capsule

-

Voltage:

-

220V/380V

-

Place of Origin:

-

China

-

Brand Name:

-

EXPAK

-

Dimension(L*W*H):

-

2990X1200X2250mm

-

Weight:

-

3000 KG

-

Product name:

-

Coffee Capsule Filling Line

-

Usage:

-

K cup Nespresso Custom Coffee Capsule Cup

-

Suitable for:

-

Ground Coffee Packaging

-

Capacity:

-

12000cups/h

-

Material:

-

Stainless Steel304

-

Control:

-

Servo Motor Control Filling Volume

-

Packing type:

-

plastic aluminum coffee capsule

-

Model Number:

-

CP5004

-

After Warranty Service:

-

Video technical support

-

After-sales Service Provided:

-

Field maintenance and repair service

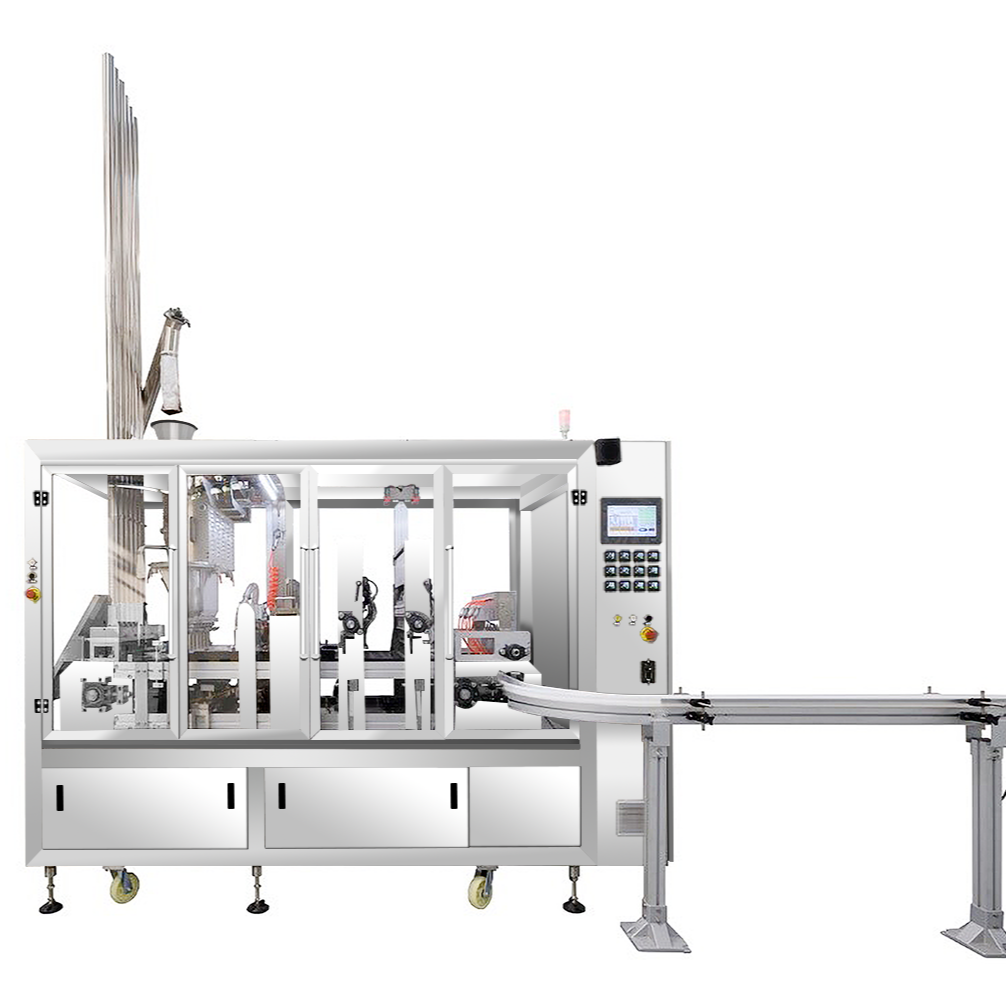

Product Overview

1 High Output Linear Four lane K Cup filling machine.

Capacity is up to 12000 Pods/Hour with updated Nitrogen Injection function.

Apply dual heat sealer station in order to better closure.

2 Based on the different needs of customers for the production of coffee pods, this model can be customized for Nespresso , which is lidding station change to punching device can online cutting and sealing.

3 This machine is super popular with medium-sized and large companies. On the one hand, the production capacity of the machine can meet their requirements, over 11000 K-Cups per hour. Note, most of our machine accessories are SMC, Omron, Schneider and other famous brands , make machine with excellent performance

2 Based on the different needs of customers for the production of coffee pods, this model can be customized for Nespresso , which is lidding station change to punching device can online cutting and sealing.

3 This machine is super popular with medium-sized and large companies. On the one hand, the production capacity of the machine can meet their requirements, over 11000 K-Cups per hour. Note, most of our machine accessories are SMC, Omron, Schneider and other famous brands , make machine with excellent performance

|

Product

|

|

CP5004 For K Cup

|

|

|

|||

|

Suitable sealing

|

|

K Cup with Precut Lid

|

|

|

|||

|

Capacity

|

|

up to 200cups per min

|

|

|

|||

|

Filling weight range

|

|

0-20g (set by customer)

|

|

|

|||

|

Accuracy

|

|

±0.2g

|

|

|

|||

|

Voltage

|

|

220V/380V 50/60hz need confirm by customer

|

|

|

|||

|

Dimension(Vertical load) (LxWxH)

|

|

3420(L)X850(W)X2200(H)

|

|

|

|||

|

Dimension(Horizontal load) (LxWxH)

|

|

4560X850X2200(mm)

|

|

|

|||

|

Packed Weight

|

|

3000KG

|

|

|

|||

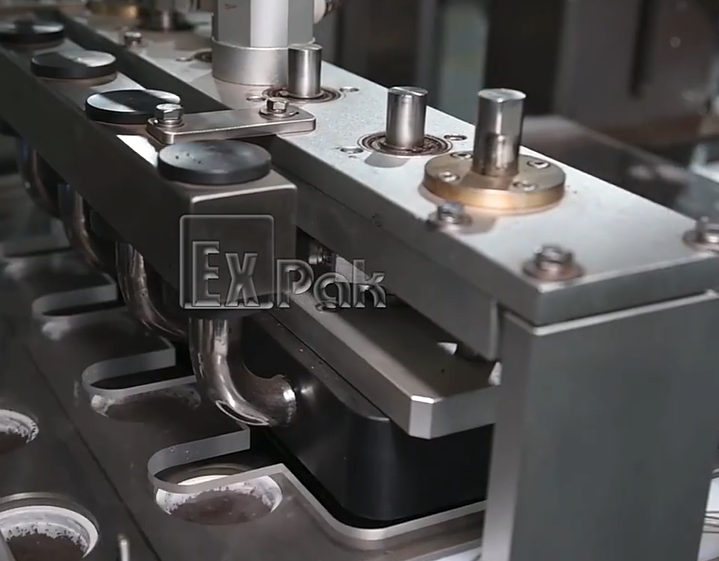

Empty Cup Loading System

Auger Filler for ground coffee

Four augers as volumetric dosing unit, drive by Schneider servo motor precisely control the auger spinning, achieve high output while ensuring stable mechanical action. Also install a compact agitator inside the hopper and making the coffee flow more uniform so that could guarantee accuracy of filling. Cone shaped hopper made of stain steel with a feature of quick dropping coffee.

Details Images

Nitrogen flush and auger filling station

Nitrogen flush can keep coffee fresh and servo motor drives auger filling accuracy.

Clean system

A clean system after filling, it can clean coffee around the cup edge, indirectly keep

tightness

with heatsealing.

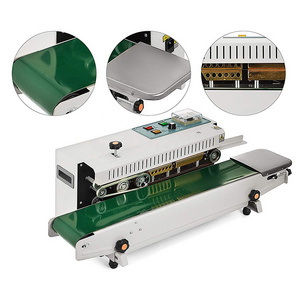

Heat Seal

Double Heat Seal (seal by two steps for a better sealing)

Feedback

The complete production line can be customized

Hot Searches