- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

Custom

-

Material Option:

-

Aluminum, Plastic, Copper, Hardened Metals, Stainless Steel, Alloy...

-

Color Size:

-

Customer's request

-

Service:

-

OEM ODM Customized

-

CNC Machining:

-

Yes

-

Tolerance:

-

0.01- +/-0.005mm

-

Surface treatment:

-

Powder coat,Eletroplat,Oxide,Anodize,Etching, Chemical,Sand blasting

-

Quality Control:

-

ROSH, CE, ISO, TUV, ETL

-

Application:

-

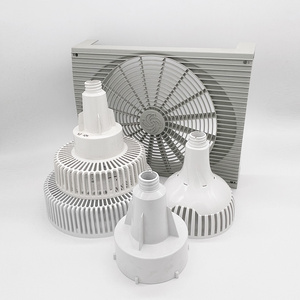

Appliance,Auto,Building,Equipment,Machinery,Household,Electrica. etc

-

Technics:

-

Bend, Weld, Stamping,Laser cutting, Machining, Cast,Wire EDM,Broaching

-

Brand:

-

YIJIAN

Quick Details

-

Shaping Mode:

-

Various

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

OEM

-

Model Number:

-

Custom

-

Material Option:

-

Aluminum, Plastic, Copper, Hardened Metals, Stainless Steel, Alloy...

-

Color Size:

-

Customer's request

-

Service:

-

OEM ODM Customized

-

CNC Machining:

-

Yes

-

Tolerance:

-

0.01- +/-0.005mm

-

Surface treatment:

-

Powder coat,Eletroplat,Oxide,Anodize,Etching, Chemical,Sand blasting

-

Quality Control:

-

ROSH, CE, ISO, TUV, ETL

-

Application:

-

Appliance,Auto,Building,Equipment,Machinery,Household,Electrica. etc

-

Technics:

-

Bend, Weld, Stamping,Laser cutting, Machining, Cast,Wire EDM,Broaching

-

Brand:

-

YIJIAN

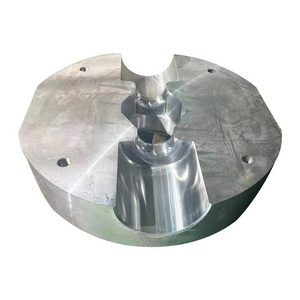

Product Specifications

|

Service

|

CNC Machining

|

Welding process

|

|

|

|

Sheet Metal Fabrication

|

Surface treatment

|

|

|

|

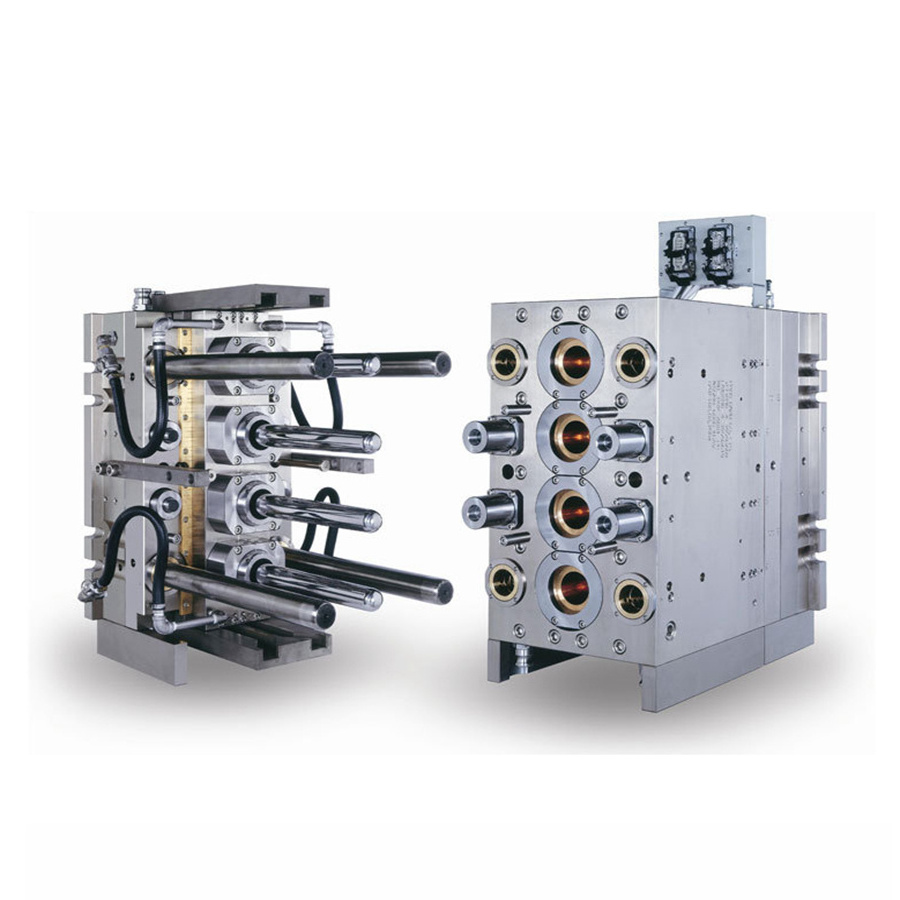

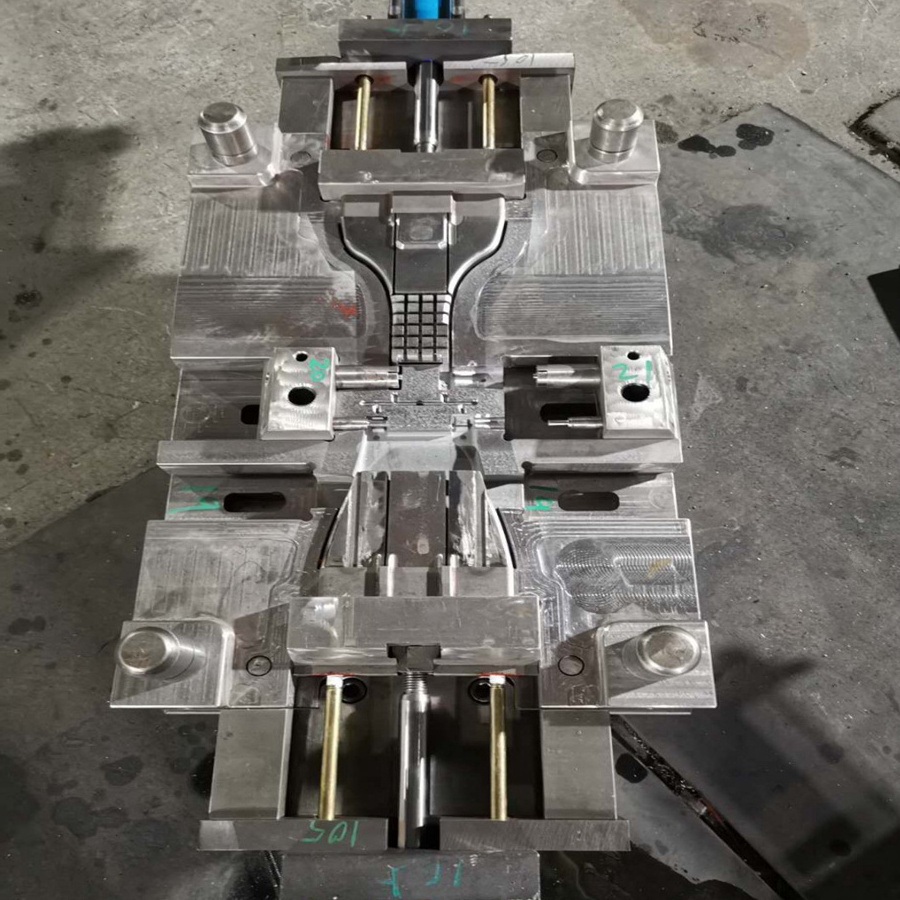

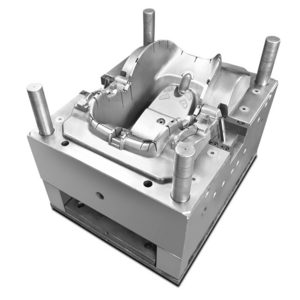

Die casting

|

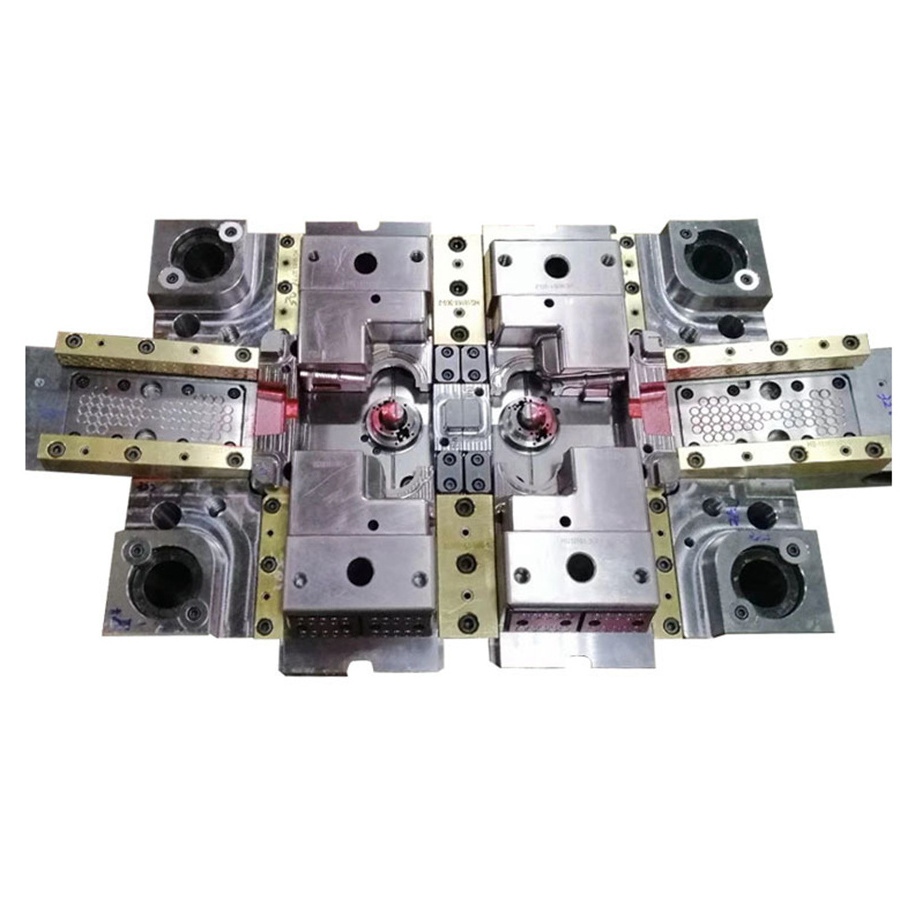

Injection(rubber&plastics)

|

|

|

|

Laser Cutting Service

|

F

orging

|

|

|

|

Molding

|

Drilling, milling, tapping

|

|

|

|

Stamping

|

Any other technology.......

|

|

|

Machinable materials

|

Aluminum, Steel, Stainless Steel, Copper, Brass, Plastic,Alloy, Molybdenum, Titanium, Etc.

|

|

|

|

Equipment types

|

CNC machining center(milling), CNC lathe, Griantry CNC machining center,Etc.

|

|

|

|

|

Cylindrical grinder machine, Drilling machine, Laser cutting machine,Etc.

|

|

|

|

|

Tube laser cutting machine,Flame cutting machine,Robert welding arm,Etc.

|

|

|

|

|

Bending machine,Stamping machine,Sand blasting machine,Powder coating line

|

|

|

|

Treatment

|

Surface treatment, Heat treatment, Anodizing,Blackening, Electroplating, Painting, Powder

coating,Passivate,Carburize,Polished,Mirror polished,Brushed, Sandblasted,Heat treatment etc.. |

|

|

|

QC

|

ROSH, SGS, CE, ISO, TUV, CSA, ETL, UL

|

|

|

|

Tolerance:

|

+/-0.001mm ~ +/- 0.00004 inch

|

|

|

|

Surface Roughness:

|

Ra 0.1-3.2

|

|

|

|

Delivery Time

|

7-50Days Depends On Quantities

|

|

|

Details Images

Partial factory equipment list

|

Equipment name

|

Model

|

Equipment name

|

Model

|

||

|

CNC lathe

|

CKA6150, KWV—850, DTX1050, LY—D2020, HTM-4228G, HTM-2028G, LGMC-1370

|

Isolation transformer

|

SG-10KVA

|

||

|

CNC machining-center

|

KMV-850, DTX1060 CNC

|

Large sawing machine

|

GB4245/65,

|

||

|

CNC vertical gantry machining-center

|

SDM-7215, HT-6428, HT-4228, LY-D2020

|

laser cutter

|

XL6015T,

|

||

|

Air compressor

|

UD18A-7CVFD, UD15A-8, DSR-30AV, V-1 05/10

|

Lathe machine

|

C630, C620-1B

|

||

|

Argon fluorine welding machine

|

AFT-300, WSME-500, WS-200, WS-300

|

Milling machine

|

3H

|

||

|

bench drill

|

ZX-16J, 228279

|

Plasma cutting machine

|

KLA-90

|

||

|

Bench drilling machine

|

24116

|

radial drilling machine

|

Z3080

|

||

|

Bending machine

|

WC67Y-700/400

|

Resistance welding machine

|

DNT615, DN-35

|

||

|

Chamfering machine

|

GD-900H

|

Riveting machine

|

THW-5B

|

||

|

Drill press

|

23080*25, 23040

|

Rolling machine

|

W11-2X100

|

||

|

Dust collector

|

KH-HY1500, HCD-120DY, KH-HY300, JN-301T, HCHYD4800, 2400

|

Small sawing machine

|

GB4230/40

|

||

|

Flame cutting machine

|

GS-4000

|

Vertical Milling Machine

|

X5034

|

||

|

Flow welder

|

BX1-400

|

welder

|

ZXEI-500

|

||

|

Other Equipment

|

CNC Bending Machine, CNC flame cutting machine, CNC Lathe machine, Welding machine, TIG welding machine, Gas metal arc welding

machine, Hoisting equipment, Aluminum alloy cutting machine, Hydraulic press, High Precision Laser cutting |

|

|

||

Why Choose Us

One-stop Solution

From mold design, mold making, machining, fabrication, welding, surface treatment, assembly, packing to shipping

Quality Guarantee

We have a professional team to control the quality. Experienced engineers, precision machines, CMM and closed-loop QC system

Customer Service

Every client is served by a specialized sales for timely technical support and after-sales service

From mold design, mold making, machining, fabrication, welding, surface treatment, assembly, packing to shipping

Quality Guarantee

We have a professional team to control the quality. Experienced engineers, precision machines, CMM and closed-loop QC system

Customer Service

Every client is served by a specialized sales for timely technical support and after-sales service

We promise:

1. All the parts from our company have no sharp edge. All dimensions are controlled according to your drawings. Every product will be fully inspected and carefully packed to prevent the bump and rust in transit.

2. The craftsmanship of all parts we machined is controlled rigorously, Every product has its own process card and process chart.

3. Our quality inspection procedure is quite strict.it must self-inspected during production, we have flow inspectors and professional inspectors.

4. Each size of product must be tested one by one after completing production and provide quality report.

5. The most important point, we are the entity factory, not trading company. Price is the composition of the actual product quality price. Quality can guarantee more controllable higher than trading company. The price is competitive, at least reducing the trade company's service fee.

6.We have many years of export experience,exports to the US,Europe, Japan and other countries and regions.

7.Our team are more professional. We have more reasonable price and better quality controlling than trade company. And our language ability is also diversified.

Shanghai Yijian Machinery Equipment Co., Ltd.

was established in 2002 and is located inJinhui Town Industrial Park, Fengxian District, Shanghai City.

Our company is a professional manufacturer who is an one-stop services

OEM

and

ODM

company ,

we providenot only a machining part but also a final machine, we are specialized in many industry OEM

and ODM

service such as Mid-large parts precision machining parts making,

All kinds of material’s welding ,mechanical and electrical assembling and painting ,

we have three independence production area(mechanical workshop,

assembling workshop and painting workshop) them are covers 10000 square meters.

1.Mechanical workshop: we have from 10 meters CNC to 850mm CNC , we can also doing all kinds of material welding process and sheet metal parts making.

2.Assembling workshop: we have a high quality and fully training team they have more than 20 years final machine assembling experience can afford any requirement you want

3.Painting workshop: we have 8 meters oven, sand blast equipment,and powder coating equipments.

High Speed, High Quality, High Cost Performance ,High Satisfaction" 4H is our service concept.

We are specialized on OEM ink jet print parts, aerospace products, automobiles, instruments and meters, metallurgy, hydraulic pressure, tunnel construction, machine facture and other fields.

The products are exported to US, Canada, Germany, France,

Japan,

and other oversea markets.

FAQ

FAQ

Q1: What certificates do you have?

A1: We have CE, COC,TUV,GS,ROHS certificates.

Q2:What is the MOQ policy?

A2: It is depending on items. The more the quantity, the cheaper our production cost and the cheaper the price. Customize color, print a logo on the item or customize the packaging, please contact

our sales department

Q3:What is your payment term

A3: Payment<=1000USD, Alibaba in advance.

Payment>=1000USD, T/T ,Alibaba,in advance

Q4:Which countries will the products be sold?

A4: UK, HK, Unites States,Germany, France , Australia, Ukraine, over 100 countries and regions

Q5:How soon can I get your response?

A5:

Our company rules that we must reply customers within 12 hours, however, the average responding time is within 5hours. If it is not a Chinese break, we will reply immediately

Q6:How soon can I get your quotation?

A6:

We are trying to quote you within 24 hours, however, it depends on drawings quantity and complicating rate. If you are really very urgent, call us or email us so that we will put it in priority.

Q7:How can I get a sample for quality check?

A7:

After quotation, if needed, you can ask for samples to check quality. We will provide you free samples(value under 15$ without tooling invest) as long as you pay freight cost by yourself.

Q8:What's your leading time for samples?

A8:

For custom metal parts, normally we can send them out within 10days.For custom stainless steel parts and aluminum parts, we can send them out within 15 days.For custom control box and meter box without electronics, we can send them out within 20days.For custom control box and meter box with electronics UL certificated. This will need long time about 60days or even longer, if only CE certificate and no assigned brand, about 30days are needed.For grommet machine, we can send them out without 10days."

Hot Searches